Marine pollution has become a major environmental issue threatening global ecosystems. Pollutants such as plastic waste, oil spills, and ship debris continue to disrupt the marine ecosystem. Among numerous pollution control technologies, due to the advantages of reduction, resource utilization, and harmlessness, pyrolysis equipment has become a crucial technical support for marine pollution solution. Pyrolysis equipment plays an irreplaceable role in pollutant treatment, resource recovery, and ecological restoration.

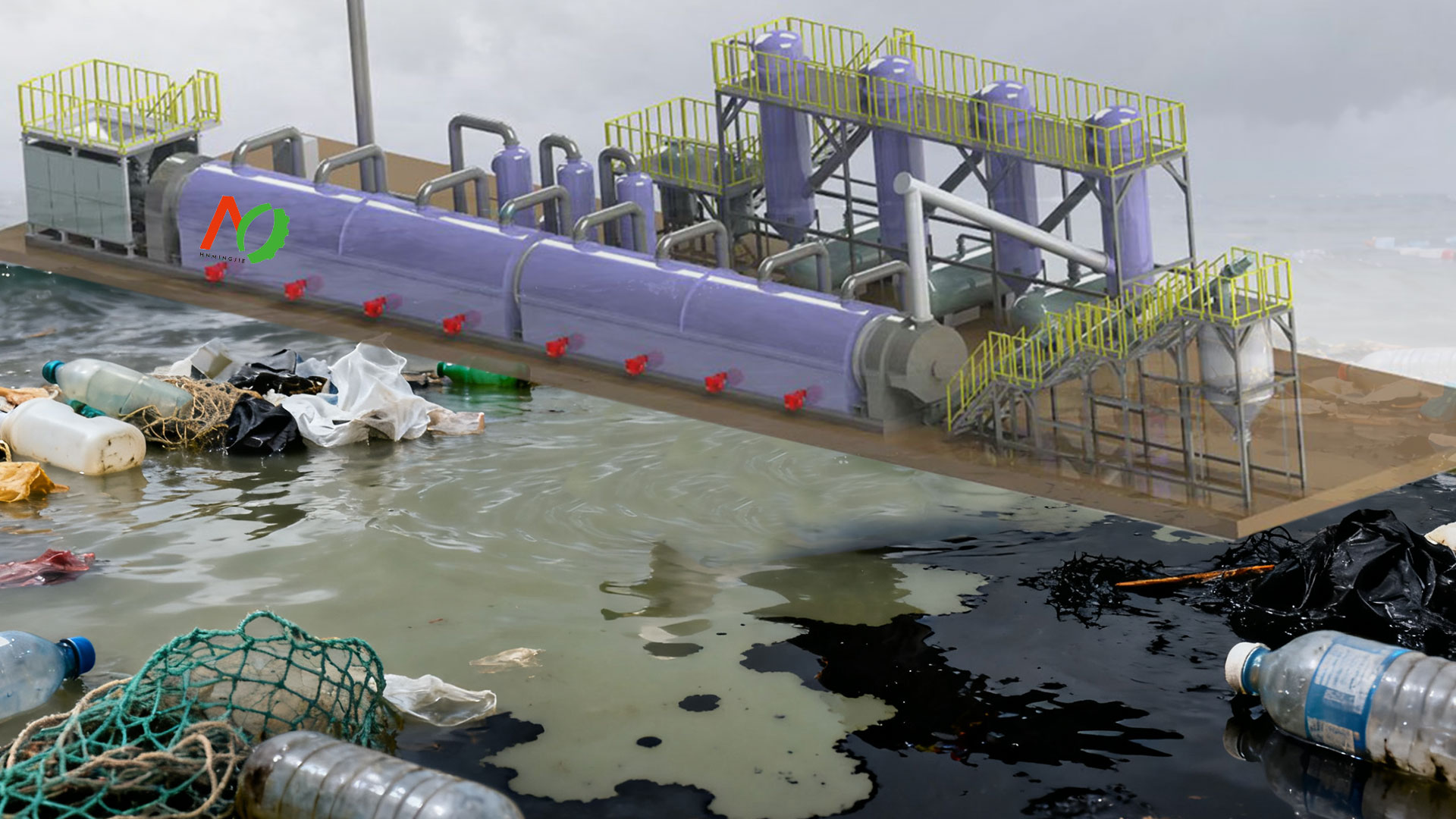

Marine Pollution Solution -Pyrolysis Plastic to Fuel Oil

Plastic marine pollution is one of the most serious marine environmental issues currently facing the ocean, with approximately 8 million tons of plastic waste entering the ocean annually. These plastics gradually decompose into microplastics in the seawater environment, permeating various links in the marine food chain. Pyrolysis equipment, using high-temperature, oxygen-free pyrolysis technology, provides an efficient solution for marine plastic waste treatment.

Plastic pyrolysis equipment decomposes common marine plastics (polyethylene, polypropylene) into small molecular compounds in an oxygen-free environment at temperatures between 300-800°C. The final products are pyrolysis oil, combustible gas, and carbon black. The volume reduction rate of plastic waste can exceed 90%, while preventing the formation of toxic substances such as dioxins, thereby eliminating the continued harm of plastic waste to the marine ecosystem at the source.

The pyrolysis oil produced by the pyrolysis can be further refined into fuels such as diesel and gasoline. Combustible gases (such as methane and ethane) can be used as energy for the pyrolysis equipment itself. Solid carbon black can be used for soil improvement or adsorption materials.

Efficient Oil Pollution Management

Crude oil, fuel, and lubricating oil leaks from ships are the primary source of marine oil pollution. This type of pollution forms an oil film on the sea surface, hindering gas exchange between seawater and the atmosphere, leading to oxygen deprivation and the death of marine life. Furthermore, toxic components in the oil can accumulate in marine organisms for a long time. Pyrolysis equipment, combining mobile and fixed deployments, provides a flexible solution for oil pollution management.

For small-scale oil spills from ships, mobile pyrolysis equipment can be deployed directly to the site of the spill. Surface oil is first collected using oil absorbent mats and booms, and then the pyrolysis equipment is used to pyrolyze the oil (and oily waste). During the pyrolysis process, hydrocarbons in the oil are decomposed into combustible gases and pyrolysis oil. This not only prevents further spread of the oil on the sea surface but also converts pollutants into usable energy.

Daily ship operations generate oily wastes such as oily sludge and waste engine oil. If discharged directly or with ballast water into the ocean without treatment, these wastes can become a significant source of land-based marine pollution. Oil sludge pyrolysis equipment centrally processes this type of oily waste. Pyrolysis technology separates the oil from solid impurities. The recovered oil can be refined into marine fuel, while the solid residue can be used as construction material or disposed of safely in landfill.

Co-processing Marine Solid Waste

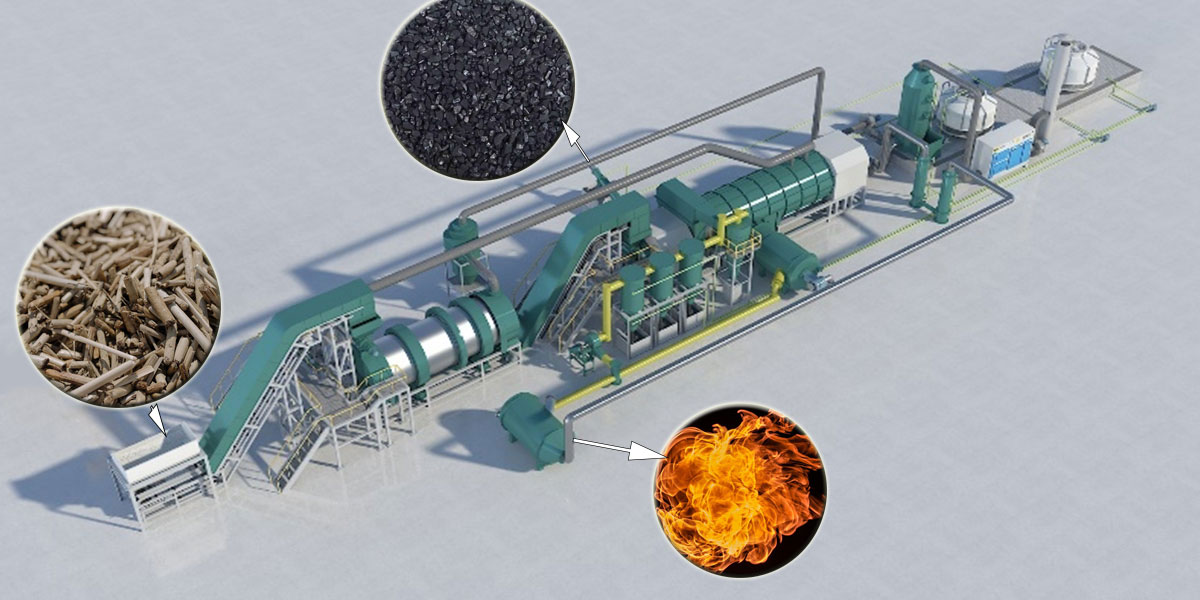

In addition to plastic and oil pollution, marine waste from fisheries (such as discarded catches and shells) and ship waste (such as paper and wood waste) also contribute to marine pollution. Pyrolysis equipment, with its wide applicability, can co-process a variety of marine solid wastes.

For fishery waste (which contains large amounts of organic matter), biomass pyrolysis equipment can convert it into biochar. Biochar can be used to improve coastal saline-alkali land and enhance soil water and fertility retention.

The biochar produced by pyrolysis has a porous structure and high adsorption capacity, making it suitable for adsorbing heavy metal ions and organic pollutants from seawater. Biochar can not only reduce pollutant concentrations in seawater, but also improve the living environment of benthic organisms, promoting the restoration of marine biodiversity.

For paper and wood materials in ship waste, the pyrolysis process efficiently breaks down their cellulose structure. The resulting combustible gas can be directly used for heating or power generation, achieving the dual goals of waste reduction and energy recovery. This prevents these wastes from rotting and deteriorating in the ocean, releasing harmful substances and contaminating the seawater.

Pyrolysis Equipment – Effective Tool for Marine Pollution Control

Amid the increasingly urgent need for global marine pollution control, pyrolysis equipment serves as a technological bridge between pollutant treatment and ecological restoration. From treating marine plastic waste and oil pollution to synergistically recycling a variety of marine solid waste, pyrolysis equipment is becoming a key force in addressing marine pollution challenges.

With further optimization and large-scale application of pyrolysis plants, their contribution to marine pollution control will become even more significant. They will provide a solid technical foundation for protecting the blue ocean ecosystem.