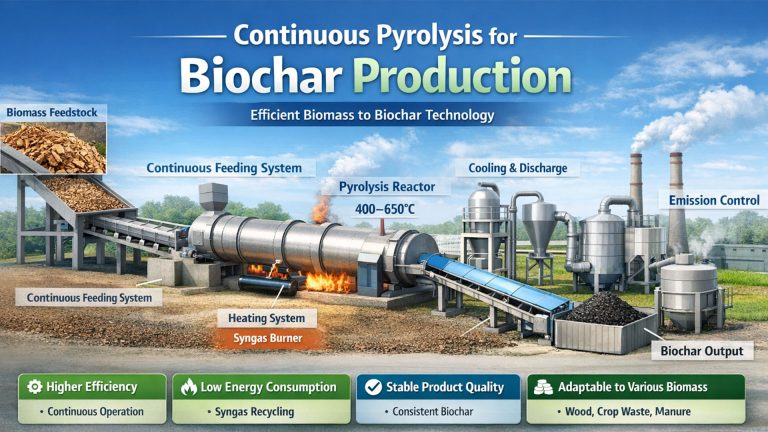

On July 24, 2025, Mingjie Group completed the shipment of MJT-2000 biochar making machine for sale to Saudi Arabia. The biochar making machine converts waste biomass such as agricultural and forestry waste, urban organic waste, livestock and poultry manure into biochar, tar and synthesis gas through pyrolysis technology. So the Biochar Making Machine is also called Biomass Carbonization Plant, Biochar Production Equipment, Biomass Charcoal Making Machine.

The MJT-2000 biochar production equipment can process up to 2000kg of biomass per hour. It rationally utilizes the synthesis gas generated by the material during the carbonization process, has a high carbonization rate, and is an ideal biomass carbonization equipment.

MJT-2000 biomass pyrolysis plant is a device that can efficiently process biomass waste and produce biochar at the same time. It realizes the resource utilization of waste, greatly reduces the environmental pollution caused by landfill and incineration, and alleviates environmental pressure from the source.

Biomass to Biochar Production Equipment for Multiple Uses

The biomass carbonization plant has a wider range of applications and can process a variety of carbon-containing wood materials such as straw, rice husks, sawdust, wood, and fruit shells.

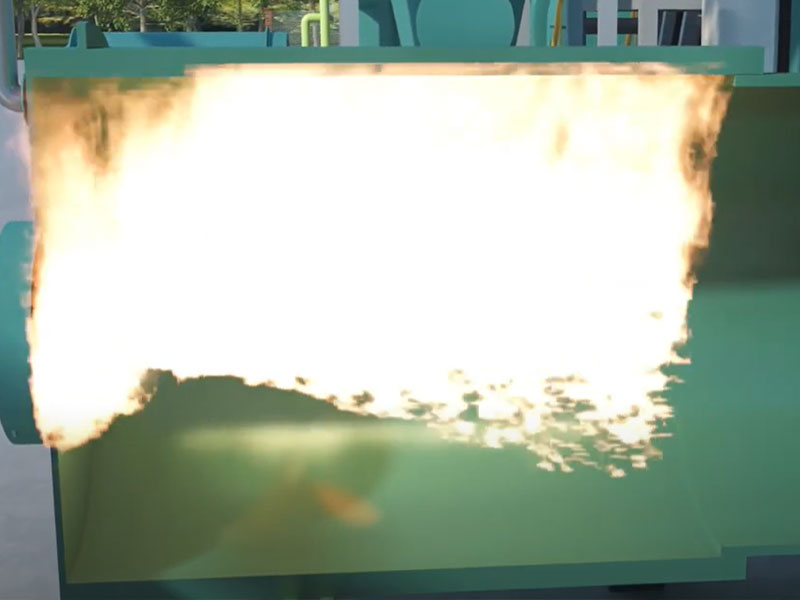

It adopts pyrolysis carbonization, which can effectively recycle and utilize the combustible gas generated during the carbonization process. This solves the problem of environmental pollution caused by the thick smoke generated in the carbonization project of ordinary carbonization furnaces. At the same time, it realizes the self-sufficiency of thermal energy of the pyrolysis equipment, and improves the continuity and economy of biochar production equipment.

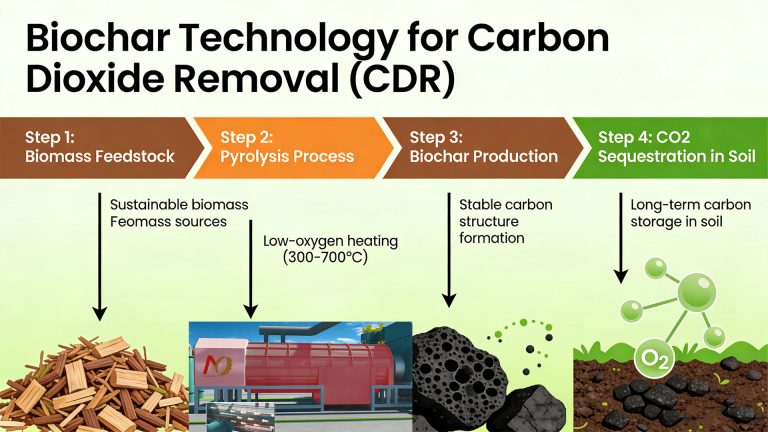

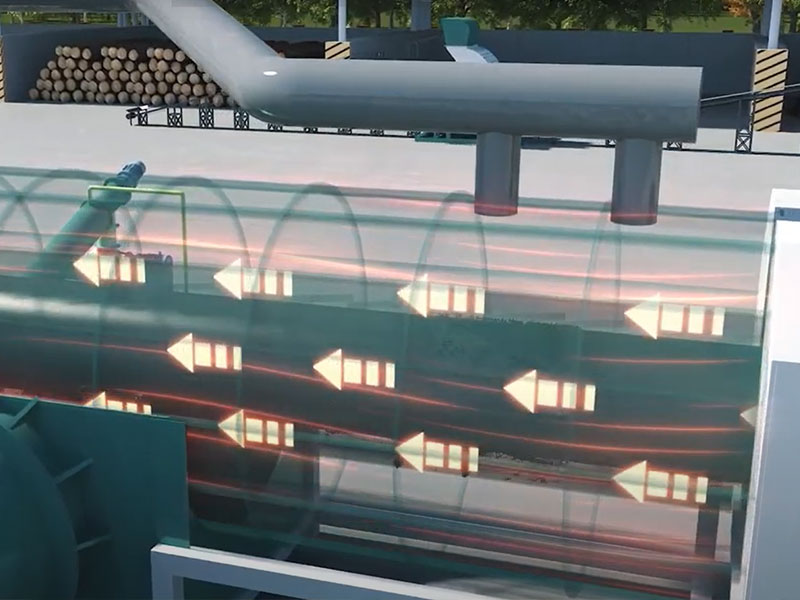

The conversion of biomass to biochar is a process of decomposing and converting biomass at high temperature in an oxygen-deficient or low-oxygen environment. When the biomass is fed into the charcoal making machine, an oxygen-deficient enclosed space is created inside the pyrolysis reactor. The temperature is then raised, and a series of complex chemical reactions begin to occur in the organic components of the biomass.

In the biomass pyrolysis products, synthetic gas escapes during the biomass pyrolysis process. After dust removal and purification, the combustible gas can be used to heat the pyrolysis reactor.

The solid part gradually carbonizes and eventually forms biochar. The pyrolysis temperature and time have a significant effect on the properties and yield of biochar. The appropriate pyrolysis temperature and time can ensure that the biomass is fully decomposed and converted, and improve the yield and quality of biochar.

Advantages of Large Biochar Making Machine for Sale

In order to improve the production efficiency and product quality of biochar, the biomass carbonization plant adopts a series of advanced technologies and unique designs.

Continuous Pyrolysis Carbonization

One of them is the continuous pyrolysis technology, which changes the traditional batch production mode and realizes the continuous feeding of biomass and the continuous discharging of biochar.

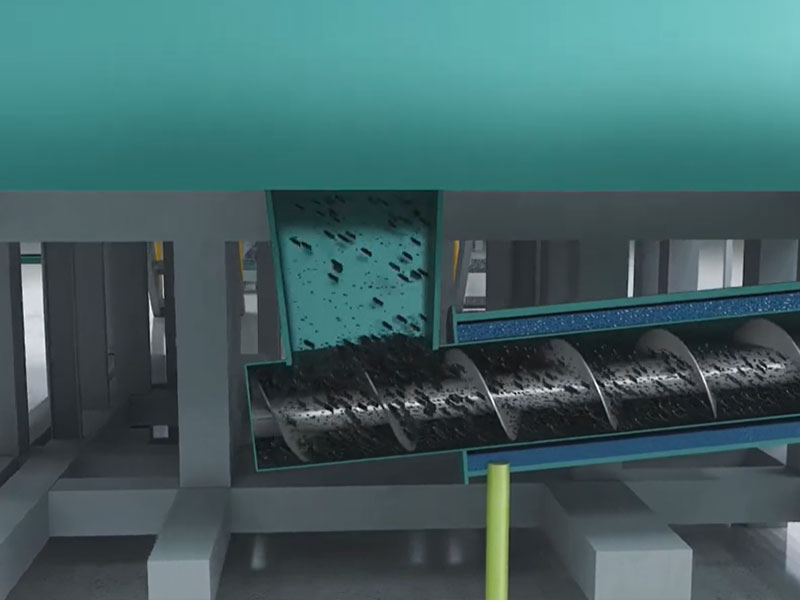

The MJT-2000 biochar making machine for sale is equipped with an automatic feeding conveyor belt and a spiral discharging device. The biomass raw materials continuously enter the pyrolysis reactor through the conveyor belt. After the pyrolysis process is completed in the reactor, the biochar is continuously output by the spiral discharging device, which greatly improves the production efficiency and reduces the production cost.

Compared with batch production, the efficiency of continuous biochar production can be increased by 3-5 times, which can meet the needs of large-scale industrial production.

High Efficiency Heat Exchange System

The efficient heat exchange system is also a major innovative design of the biochar making machine for sale. The system uses the waste heat of high-temperature flue gas generated during the pyrolysis process to preheat the biomass raw materials. Through this system, the energy consumption in the subsequent biomass pyrolysis process can be reduced. At the same time, the cooling system can quickly cool the biochar to room temperature for subsequent collection and storage.

It has been calculated that after adopting the efficient heat exchange system, the energy utilization rate of the charcoal making machine can be increased by 20-30%, effectively reducing the energy consumption cost.

Intelligent Control System

The biochar making machine for sale is also equipped with an intelligent control system. The system monitors the temperature, pressure, material flow and other parameters inside the manufacturing machine in real time through sensors, and automatically adjusts the operating status of the equipment according to the preset program. This intelligent control not only improves the stability and reliability of the biochar production process, but also reduces manual intervention.