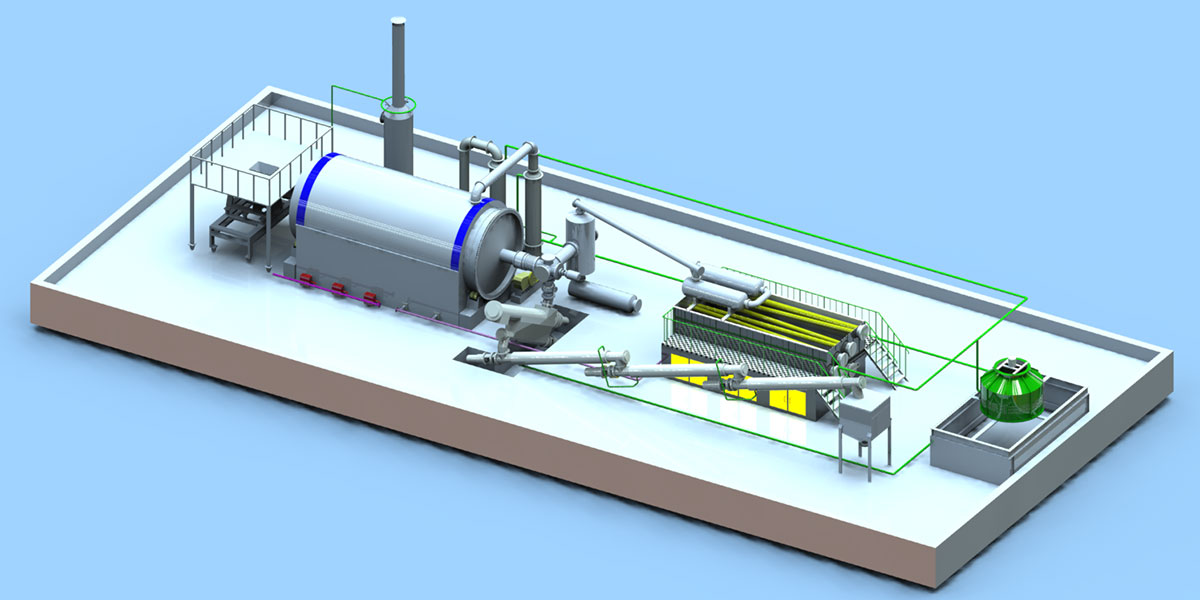

Potential cost components of plastic pyrolysis project include: plastic pyrolysis plant cost (reactor, pre-treatment, post-treatment), raw material handling, energy consumption, labor, permits, and environmental protection measures.

A small pyrolysis plant cost is may from $45,000 to $150,000. Assuming a $100,000 investment in equipment and an 8-year useful life, the annual equipment depreciation cost is approximately $12,500.

The purchase price of waste plastics varies depending on the type and quality, with an average purchase cost of about $100-200 per ton. The monthly raw material cost for processing 10 tons of waste plastics per day is between $30,000 and $60,000.

Operating costs include labor, water, electricity, and maintenance costs. Labor costs are about $5,000-8,000 per month, and water and electricity costs are about $3,000-5,000 per month. Equipment maintenance costs are about $2,000-3,000 per month. The total monthly operating cost is about $10,000-16,000.

The plastic pyrolysis plant cost varies widely, depending on capacity, equipment quality, and environmental requirements. For example, plastic pyrolysis plant may require more advanced pre-treatment equipment and emission purification systems to improve product quality, which may increase costs.

Plastic Pyrolysis Plant Cost

Small Pyrolysis Plant (2-15 t/d)

These batch pyrolysis units are ideal for small businesses or areas with limited waste supply. Batch plastic pyrolysis plant cost is typically between $20,000 and $1 million. For example, skid-mounted small pyrolysis plant starts at $20,000, while a 6-15 t/d batch pyrolysis plant costs about $60,000-100,000.

Medium-Sized Pyrolysis Plant (15-50 t/d)

Semi-continuous or fully continuous pyrolysis plant can process larger waste streams. Plastic pyrolysis plant cost ranges from $1.5 million to $5 million. These systems include advanced automation and higher emission purification systems.

Pre-treatment: The cost of shredders and dryers may add $200,000 to $1 million.

Post-treatment: A distillation unit to purify pyrolysis oil may cost $500,000 to $3 million, depending on capacity.

Large-Scale Pyrolysis Plant (50+ t/d)

The high-capacity fully automatic high-capacity plastic pyrolysis plant cost is from $5 million to $50 million+. A continuous pyrolysis plant with 25 t/d capacity and integrated pyrolysis oil distillation plant can cost between $8 million and $12 million. A fully automatic plastic pyrolysis plant with multiple reactors and purification units that processes 100 t/d can cost more than $30 million.

Plastic Pyrolysis Project Profit Analysis

Fuel oil produced by pyrolysis is one of the main sources of income. In the international market, the price of fuel oil is usually between 500 and 800 US dollars per ton. Assuming a small pyrolysis plant that processes 10 tons of waste plastics per day, the oil yield is calculated at 40%. 4 tons of fuel oil can be produced per day, and 120 tons per month (based on 30 days). If sold at 600 US dollars per ton, the monthly fuel oil sales revenue can reach 72,000 US dollars.

Carbon black produced by pyrolysis also has market value, and the price is generally between 200 and 400 US dollars per ton. Similarly, 10 tons of waste plastics are processed per day, and the carbon black output rate is 20%. 2 tons of carbon black can be produced per day, and 60 tons per month. If sold at 300 US dollars per ton, the monthly carbon black sales revenue is 18,000 US dollars.

The combustible gas produced during the pyrolysis process can be used for heating or power generation in the factory itself. This saves energy costs and indirectly increases profits. If it is purified and sold to the outside, it can also bring in a certain amount of income. However, this part of the market is relatively small and has high requirements for gas quality.

ROI of Plastic Pyrolysis Projects

The return on investment (ROI) of plastic pyrolysis project is a key indicator for measuring the profitability. It is affected by a combination of factors, such as raw material costs, product market prices, operating costs, and policy subsidies.

Assuming a small-scale plastic pyrolysis project with monthly revenue of $90,000, the total monthly cost is about $52,500 – $88,500. Taking the middle value of $70,500, the monthly net profit is about $19,500.

The annual net profit is about $234,000. The equipment investment is $100,000. According to this profit level, the payback period is about 0.43 years, and the return on investment = (annual net profit ÷ initial investment) × 100% = (234,000 ÷ 100,000) × 100% = 234%.

However, in actual situations, ROI is affected by fluctuations in many factors. For example, when fuel oil market prices fall and raw material supply is unstable, leading to rising operating costs, ROI will drop significantly. At the same time, some local governments provide tax incentives, subsidies and other policies for plastic pyrolysis projects, which can effectively improve the ROI of plastic pyrolysis projects.

In Summary

Plastic pyrolysis projects have a high return on investment under ideal conditions. However, in actual operations, it is necessary to pay close attention to market dynamics and cost control to ensure the profitability of the project. If you want to know more about the ROI of plastic pyrolysis projects, you can provide more information and Mingjie Group will provide you with further analysis.