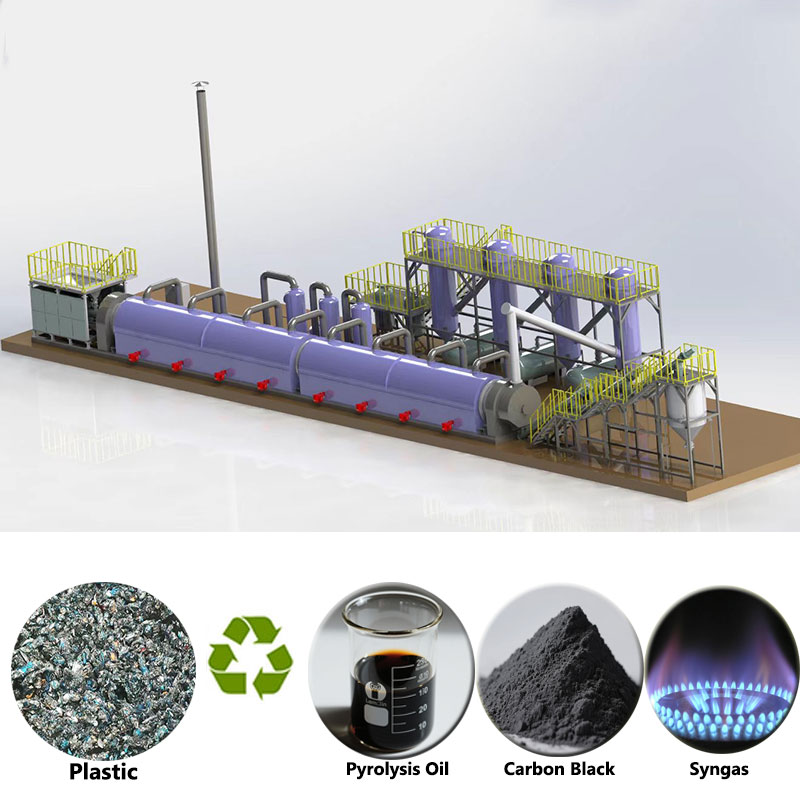

Plastic pyrolysis plant can transform discarded plastics into valuable products, such as fuel oil, synthesis gas, and carbon black. These plastic pyrolysis products have broad application prospects in various fields, including energy, chemicals, and materials. It is gradually changing our view of plastic waste and providing a new way to achieve resource recycling and environmental protection.

Main Plastic Pyrolysis Products

During the pyrolysis process, plastic undergoes a series of complex chemical reactions, breaking down into various product forms, primarily gases, liquids, and solids.

Gaseous Products – Syngas

Plastic pyrolysis produces a rich variety of gaseous products, primarily including hydrogen, methane, ethylene, propylene, and other small hydrocarbon molecules. The plastic pyrolysis products synthesis gases have high calorific value and are highly useful in the energy sector. Their presence creates a virtuous cycle of plastic pyrolysis products, providing strong support for the sustainable development of the plastics industry.

Hydrogen, for example, is a clean energy source, producing only water upon combustion and causing no environmental pollution. Hydrogen is widely used in fuel cell vehicles and other applications, offering new hope for addressing energy crises and environmental pollution.

Methane is also an important component of natural gas, playing a key role in home heating and power generation. Ethylene and propylene are crucial building blocks of the chemical industry, and are important raw materials for the production of plastics, such as polyethylene and polypropylene.

Liquid Products – Pyrolysis Oil

The main liquid product is pyrolysis oil, a complex mixture containing a variety of organic compounds, including alkanes, alkenes, and aromatics.

Due to differences in chemical structure and composition, the composition of the plastic pyrolysis products pyrolysis oil varies depending on the source of the plastic. The pyrolysis temperature also significantly affects the composition of pyrolysis oil. At lower temperatures, pyrolysis oil may contain higher concentrations of long-chain alkanes and olefins. As the temperature increases, the aromatic content in the oil gradually increases.

Plastic pyrolysis oil has a wide range of uses. Plastic pyrolysis oil is refined and processed in pyrolysis oil distillation plant into fuels such as gasoline and diesel for use in transportation. Plastic pyrolysis oil can also be used as a chemical raw material in the production of various chemicals.

Solid Products – Carbon Black

The solid product is primarily carbon black. Carbon black is an industrially valuable material with excellent reinforcing, coloring, and electrical conductivity. Plastic pyrolysis products carbon black plays an indispensable role in industries such as rubber, inks, and coatings.

In the rubber industry, carbon black significantly improves the strength, wear resistance, and aging resistance of rubber products. In the ink and coating industries, carbon black serves as a high-quality colorant, enhancing the aesthetics and quality of products.

Energy Applications of Plastic Pyrolysis Products

With the growing demand for energy, the combustible gases and pyrolysis oils from plastic pyrolysis products have become a hot new fuel source, attracting considerable attention in the fuel industry. Syngas from plastic pyrolysis products, such as hydrogen and methane, are high-quality fuel components.

Pyrolysis oil also possesses significant fuel value. After proper refining and blending, it can serve as a gasoline and diesel alternative. Compared to traditional fossil fuels, pyrolysis oil offers several unique advantages. Derived from waste plastics, it is a renewable resource. This means its use can reduce dependence on finite fossil fuels and mitigate energy supply risks.

The production process for pyrolysis oil is relatively simple, and Mingjie pyrolysis plant and distillation plant can convert plastics into diesel, making it economically competitive. Plastic pyrolysis oil has excellent combustion properties and can provide stable engine power.

In many regions, fuel produced from plastic pyrolysis is already being used for power generation and heating.

Large-scale plastic pyrolysis plant projects are being built to convert large quantities of waste plastic into combustible gas and pyrolysis oil. Th pyrolysis products are then transported to nearby power plants and heating stations for use in power generation and heating.

According to statistics, plastic pyrolysis projects can reduce carbon dioxide emissions by hundreds of thousands of tons annually, equivalent to planting millions of trees. They also enable the resource utilization of waste plastic, reducing the amount of landfill and incineration, and reducing environmental pollution.