Waste plastic pyrolysis oil (WPPO) is a new and potentially valuable raw material produced during the pyrolysis process of waste plastics. Plastic waste to energy plant recycles waste plastics through pyrolysis. They use heat at 300°C-600°C in the absence of oxygen to decompose waste plastics and municipal solid waste, producing the corresponding pyrolysis oil.

Pyrolysis of plastics is a chemical recycling technology. Compared to traditional plastic mechanical recycling plants, pyrolysis plastic waste to energy plant can produce higher-value fuel oil.

Amidst the growing global threat of plastic pollution, the application of pyrolysis technology is expected to expand. And the waste plastic pyrolysis oil industry is expected to expand accordingly. Internationally, waste plastic pyrolysis oil producers include ExxonMobil, Shell, Petronas Chemicals Group (PCG), Neste, ENVIRO Industries, Japan, and SK Geo Centric, South Korea.

The liquid oil produced from plastics is of exceptional quality. It can be used in a variety of applications, including furnaces, boilers, generators, and diesel engines. Waste plastic pyrolysis oil can be used as a substitute for fossil fuels, and its application can reduce the dependence of various fields on fossil fuels.

Furthermore, the syngas from plastic plastic waste to energy plant has a high calorific value, making it suitable for meeting the energy needs of the plastic pyrolysis plant itself.

Compared to traditional recycling methods, plastic pyrolysis is preferred due to its simpler and more flexible handling. Unlike recycling, pyrolysis does not pose water pollution issues. It is considered a green technology, and the syngas byproduct of pyrolysis has a high calorific value and can be recycled to meet the energy needs of the pyrolysis plastic waste to energy plant.

How to Get Fuel from Plastic Waste To Energy Plant

Pyrolysis technology is currently the most widely used conversion method in plastic waste to energy plant. It involves heating plastics to 300-800°C in an oxygen-free or oxygen-deficient environment, breaking down the macromolecular chains into smaller hydrocarbons. This ultimately produces pyrolysis oil, combustible gas, and solid carbon black.

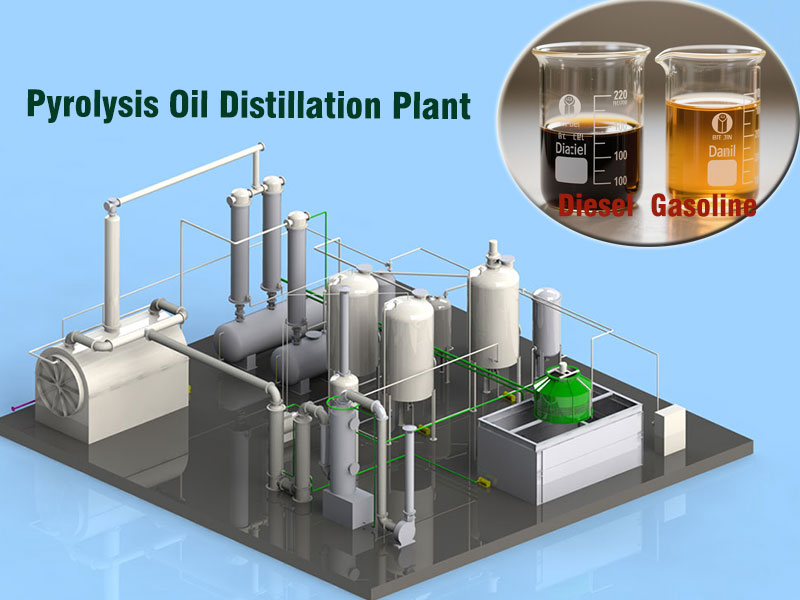

Pyrolysis oil, with a composition similar to diesel. It can be used directly as boiler fuel or further refined into diesel, gasoline by pyrolysis oil distillation plant.

Mingjie continuous pyrolysis plant can efficiently convert waste plastics into pyrolysis oil, producing approximately 0.7 tons of pyrolysis oil per ton of waste plastic. The key to converting plastics into energy lies in precisely controlling temperature and reaction time. High temperatures can lead to carbonization of the products, while too low temperatures can result in incomplete conversion of the plastics into fuel oil.

Syngas needs to be purified before use. It can be used in the heating system of pyrolysis plant. We provide dust removal and purification systems for pyrolysis plants, which can help remove hydrogen sulfide, carbon dioxide and solid particles from the combustible gas.

Plastic Pyrolysis Technology Application

The global commercial application of pyrolysis technology for the plastic waste treatment is booming. Pyrolysis plastic waste to energy plants are being implemented worldwide, effectively addressing plastic waste pollution and generating substantial economic benefits through resource conversion. As the technology continues to mature and improve, pyrolysis technology is expected to play an even more important role in the global plastic waste treatment sector.

Mingjie Group provides both batch and continuous pyrolysis plants for plastic waste to energy plant. These pyrolysis plants can process municipal solid waste, medical plastic waste, and mixed plastic waste. Through pyrolysis reactions, they convert waste into high-quality pyrolysis oil, carbon black, and syngas.

Mingjie plastic pyrolysis plant currently exports to dozens of countries worldwide. The Czech customer uses semi-continuous pyrolysis equipment to achieve a complete closed-loop chemical recycling of waste plastics. The Thai customer utilizes semi-continuous pyrolysis equipment to recycle plastic waste from household waste that is difficult to physically recycle. The resulting pyrolysis oil undergoes further processing to produce gasoline and diesel fractions, which are then blended and used as fuel.