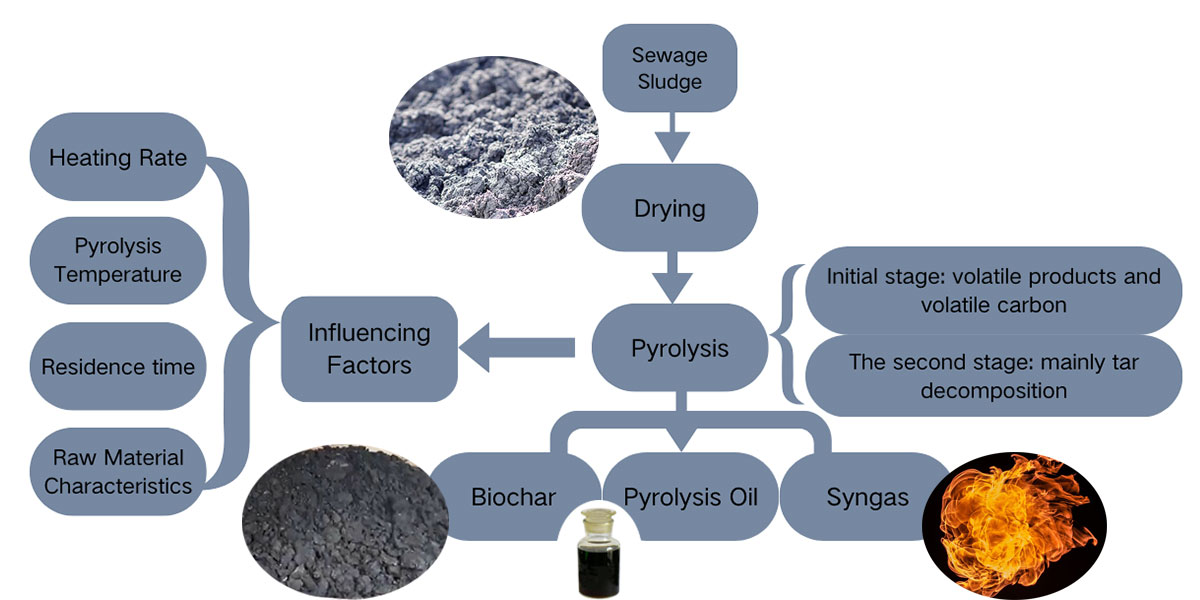

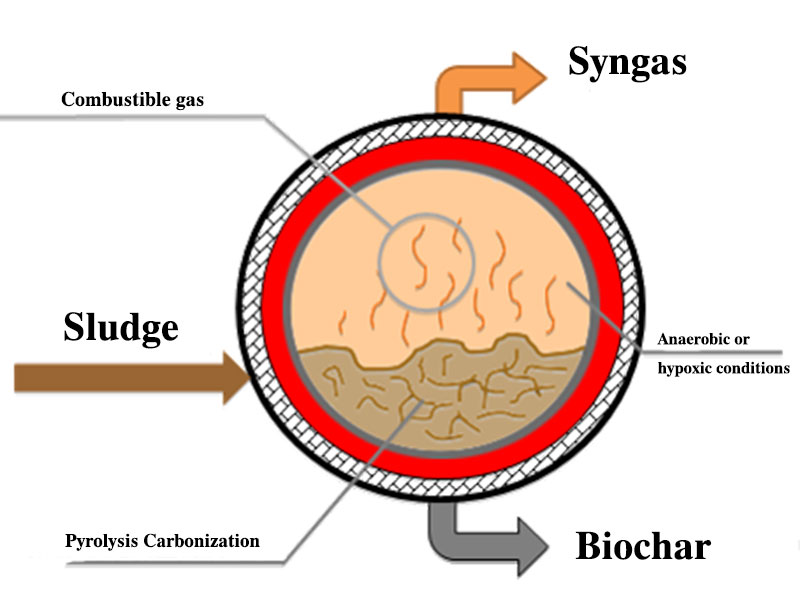

The pyrolysis of sewage sludge is a perfect environmental solution, transforming the burden of sewage sludge into energy and resources. Pyrolysis, as an emerging thermochemical conversion technology, achieves sludge reduction, harmlessness, and energy conversion. It perfectly aligns with the development concepts of a circular economy and zero-waste cities.

Sewage sludge has a complex composition, containing a large amount of organic matter, pathogens, heavy metals, and microplastics. Pyrolysis of sewage sludge effectively destroys organic pollutants and pathogens. It also fixes heavy metals in solid residues, significantly reducing environmental risks.

Pyrolysis plant can convert organic matter in sewage sludge into valuable products, such as solid biochar, syngas, and tar. While reducing environmental pollution, it can also generate significant economic benefits.

Four Factors Influencing Pyrolysis of Sewage Sludge

There are four main factors that affect pyrolysis of sewage sludge: heating rate, pyrolysis temperature, residence time and raw material characteristics.

Heating Rate

The heating rate plays a crucial role in the sewage sludge pyrolysis process, depending on the properties and composition of the final product. The sludge pyrolysis process is divided into three main stages: dehydration, organic matter weight loss, and inorganic salt decomposition. The second stage, with the highest weight loss rate, is the primary pyrolysis process.

During the sewage sludge pyrolysis stage, the primary losses are residual water and easily decomposable organic compounds, such as aliphatic compounds and cellulosic biomass. Generally, the mass loss rate increases with increasing heating rate. Samples with higher moisture content have higher maximum water loss rates and lower maximum volatile release rates. As the moisture content decreases, volatile release characteristics gradually increase.

Pyrolysis Temperature

Effect of Pyrolysis Temperature on Biochar

Sludge biochar, the primary product of the sewage sludge pyrolysis process, is rich in carbon matrix. Increasing the pyrolysis temperature decreases the biochar’s total nitrogen content, water absorption capacity, and cation exchange capacity (CEC). This increases the stability of heavy metals in the biochar.

Effect of Pyrolysis Temperature on Syngas

The main gas components produced by pyrolysis of sewage sludge are H₂, CO, CO₂, and CH₄, along with C₂-C₆ hydrocarbons. Gases produced at low temperatures are primarily composed of non-condensable gases such as CH₄, CO₂, and CO.

As the temperature increases, the pyrolysis reaction rate accelerates, leading to increased thermal decomposition of organic matter and the formation of more pyrolysis gas. The gas composition changes with increasing temperature. In addition to non-C₂, more condensable gases (hydrogen, ethane, and ethylene) are also produced.

Effect of Pyrolysis Temperature on Pyrolysis Oil

Pyrolysis oil produced from sewage sludge is a complex mixture containing water, organic compounds, and other components. It is a potential source of light hydrocarbons, such as benzene, toluene, and xylene.

After pyrolysis, sludge pyrolysis oil becomes more viscous due to the loss of volatile matter. Sludge with lower ash and volatile content is more suitable for bio-oil production. However, acids, aldehydes, and other compounds in sludge give pyrolysis oil a noticeable unpleasant odor.

Residence time

Residence time refers to the time that sewage sludge remains in the pyrolysis equipment during pyrolysis. Conventional sludge pyrolysis is generally categorized into rapid pyrolysis, slow pyrolysis, and flash pyrolysis. Flash pyrolysis and rapid pyrolysis (shorter residence times) produce higher bio-oil yields. Slow pyrolysis (longer residence times) significantly increases solid product yields.

In terms of sludge pyrolysis product yields, the following order is achieved: flash pyrolysis > rapid pyrolysis > slow pyrolysis (bio-oil), and slow pyrolysis > rapid pyrolysis > flash pyrolysis (biochar and pyrolysis gas).

Raw Material Characteristics

Sludge from different sources can contain significantly different elements, which can also affect the pyrolysis products. The quality of biochar depends largely on the fixed carbon content in the sludge.

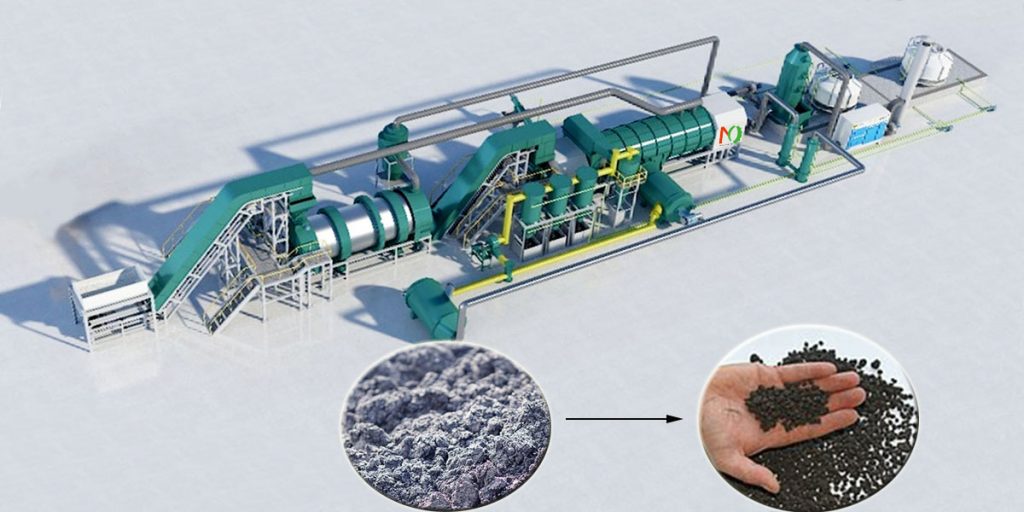

Solution for Sewage Sludge Pyrolysis

To address these factors affecting sewage sludge, the Mingjie biomass pyrolysis plant adopts an advanced intelligent control system. This intelligent temperature control system uses sensors to monitor temperature changes during the pyrolysis process in real time. It automatically adjusts heating power according to a preset temperature curve, achieving precise temperature control. Optimized flow guides and agitation devices within the pyrolysis reactor also help improve material flow and temperature distribution.

To separate the sludge pyrolysis products, the biochar production equipment utilizes a combination of multi-stage condensation and adsorption. This deeply purifies the pyrolysis gas, first removing most of the water vapor and tar through multi-stage condensation. Then, adsorbents such as activated carbon are used to further remove any remaining impurities, enhancing the purity of the pyrolysis gas.