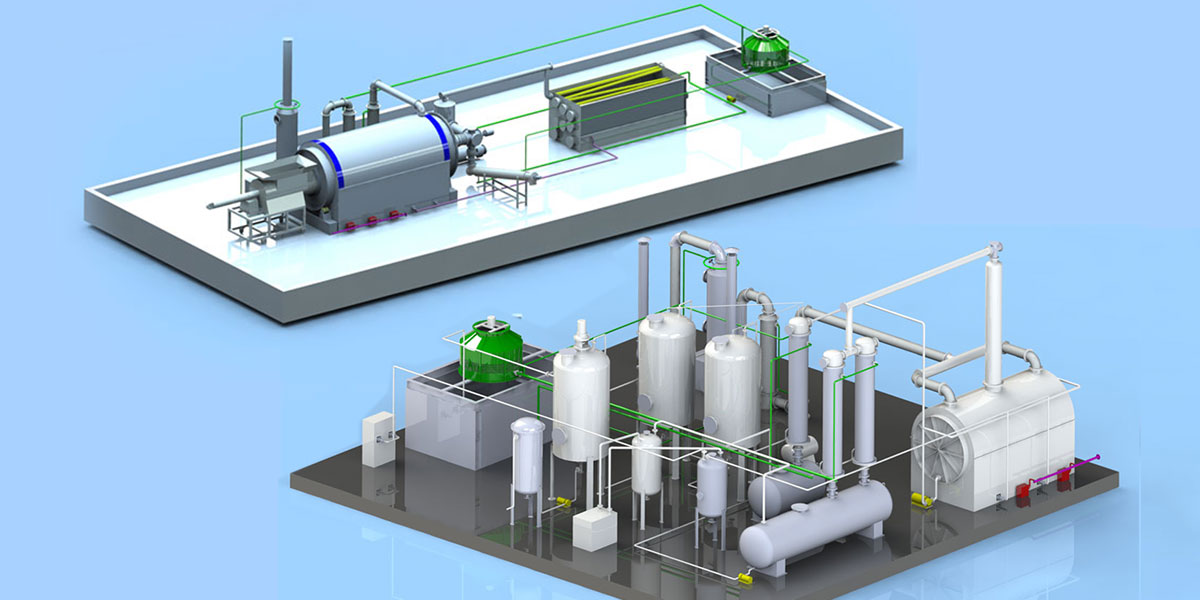

Mingjie Group provides plastic pyrolysis plant and pyrolysis oil distillation plant for pyrolysis plastic to diesel. They play a key role in connecting upstream and downstream in the plastic waste resource utilization industry chain, and jointly realize the transformation of “waste plastic → pyrolysis oil → diesel”.

The core of plastic pyrolysis plant is decomposition, breaking down large plastic molecules in a high-temperature, oxygen-free environment.

The core of pyrolysis oil distillation plant is purification from pyrolysis oil to diesel. Raw pyrolysis oil, like mixed crude oil, contains a large number of olefins and impurities. It must be distilled into different fractions.

How to Choose Pyrolysis Plastic To Diesel Equipment

When selecting equipment for pyrolysis plastic to diesel production, environmental compliance and economic costs must be fully considered.

From an environmental perspective, the plastic pyrolysis process produces a large amount of harmful gases and solid waste. If not properly handled, these can cause serious environmental pollution. Therefore, it is important to choose a pyrolysis system equipped with advanced exhaust gas treatment and solid waste disposal equipment.

From an economic perspective, equipment price, operating costs, and maintenance costs are all important considerations. When purchasing pyrolysis plastic to diesel equipment, it is important to select cost-effective equipment, comprehensively evaluating factors such as performance, quality, and service life.

Main System of Waste Plastic Pyrolysis To Fuel Oil Plant

The core function of plastic pyrolysis plant is to convert mixed/low-value waste plastics into primary pyrolysis products (pyrolysis oil, syngas, and carbon black). The pyrolysis plant can process waste plastics unsuitable for mechanical recycling (such as films, composite packaging, and contaminated plastics).

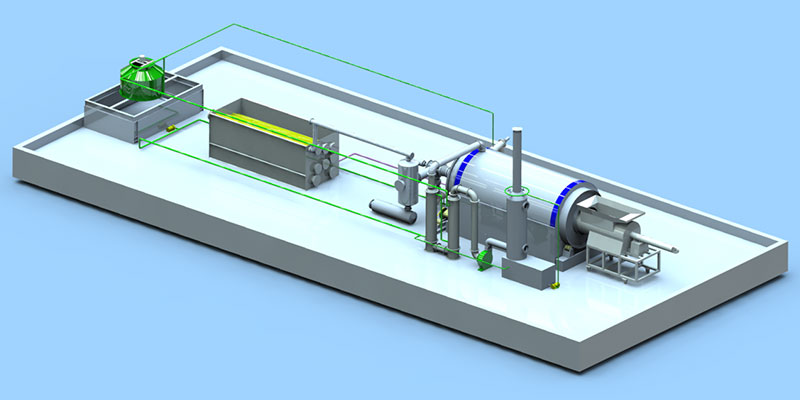

Plastic pyrolysis plant includes feeding system, pyrolysis reactor, condensation system, slag discharge system, purification system, and control system. The pyrolysis oil distillation plant mainly includes distillation reactor and refining system.

Pyrolysis Reactor

The pyrolysis reactor is the core equipment in the entire pyrolysis plastic to diesel process. Under high temperature, it breaks down the plastic’s molecular chains, causing a pyrolysis reaction and converting high-molecular-weight polymers into low-molecular-weight compounds. This process is a key step in pyrolysis plastic to diesel. The performance of the pyrolysis reactor directly affects the pyrolysis efficiency, product quality, and the energy consumption and cost of the entire plastic pyrolysis to fuel oil production process.

After the pyrolysis reaction in the pyrolysis furnace, the plastic pyrolysis products are primarily a mixture of gases, liquids, and carbon black. To obtain high-purity fuel oil products, the plastic pyrolysis oil require further processing in oil-gas separation and refining equipment.

Condenser System

The condenser system plays a key role in the oil-gas separation process. The high-temperature mixed gas produced by pyrolysis enters the condenser and undergoes heat exchange with the cooling medium (water) within the condenser. Because the cooling medium’s temperature is lower than the dew point of each component in the mixed gas, the gaseous substances in the mixed gas gradually release heat, cooling down. This leads to a phase change, from gas to liquid.

Take a common water-cooled condenser as an example. The pyrolysis mixture enters the condenser through a pipe, while cooling water flows outside the pipe. The two exchange heat through the pipe walls. The water vapor in the mixture is first cooled and condensed into liquid water. As the temperature further decreases, the pyrolysis oil vapor gradually condenses into a liquid state.

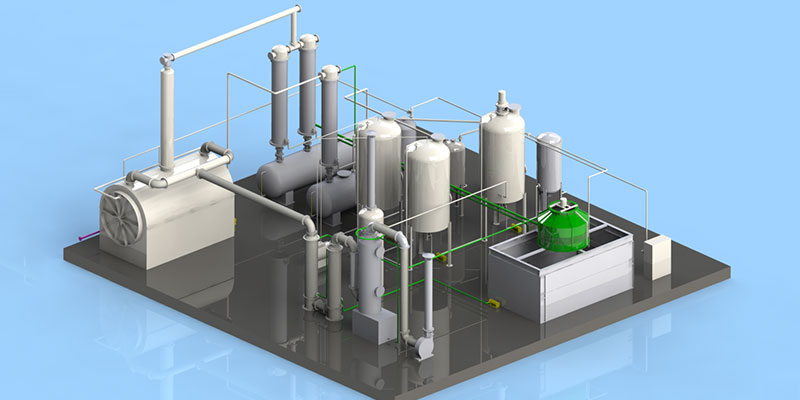

Distillation Reactor

The distillation reactor is a key pyrolysis plastic to diesel equipment for separating components in a mixture. After the mixed liquid exiting the condenser enters the fractionating tower, it begins to boil and vaporize under the influence of a heat source at the bottom of the tower, producing vapor that rises.

In the fractionation process for producing diesel from plastic pyrolysis, the low-boiling-point gasoline fraction is first separated at the top of the tower. The diesel fraction is collected at a suitable location in the middle of the tower, while the remaining high-boiling-point residue, such as residue, remains at the bottom.

The filler within the fractionating tower provides a place for sufficient gas-liquid contact, enhancing the efficiency of mass and heat transfer between the gas and liquid. This effectively separates the different components in the mixed liquid, allowing us to obtain a relatively pure diesel fraction.

Refining System

The diesel fraction obtained after fractionation may still contain impurities such as sulfur, nitrogen, oxygen compounds, and unsaturated hydrocarbons. These impurities can affect the quality and performance of diesel, necessitating further treatment through refining equipment.

The operating principles of refining equipment are primarily based on chemical reactions and physical adsorption processes. These refining processes can effectively reduce the impurity content in diesel and improve its cetane number, combustion performance, and other indicators.

Exhaust Gas Treatment System

The pyrolysis plastic to diesel process produces exhaust containing a variety of harmful gases. If these gases are released directly into the atmosphere, they pose a serious threat to the environment and human health. Therefore, exhaust gas treatment equipment is essential. Its purpose is to purify the exhaust gas generated by pyrolysis and ensure it meets environmental standards before discharge.

Common exhaust gas treatment equipment includes spray towers, activated carbon adsorption units, and catalytic combustion units. They remove pollutants from exhaust gas using different principles.