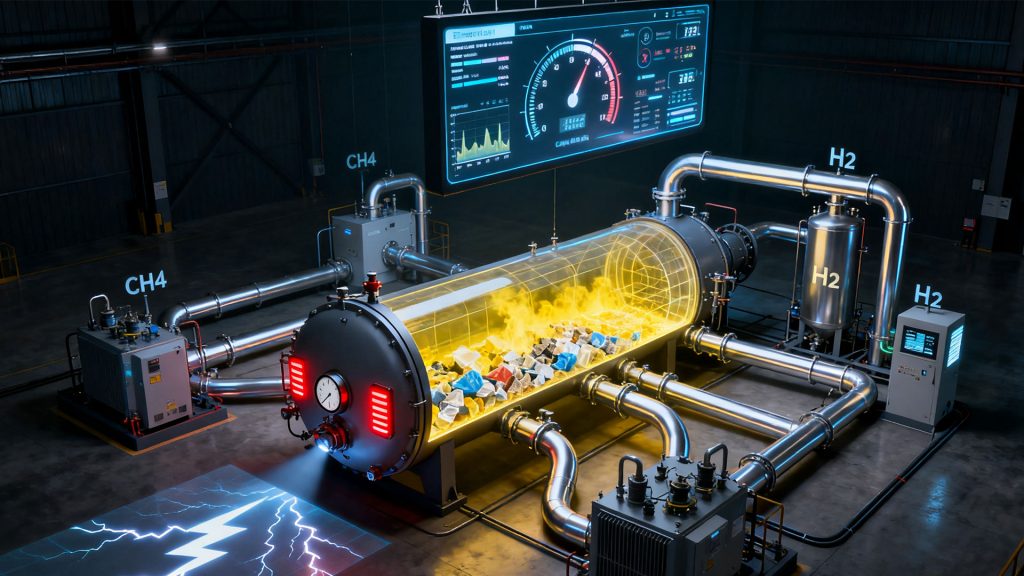

With its unique ability to transform waste into energy, pyrolysis waste to oil machines have demonstrated significant application value in a wide range of fields. Pyrolysis equipment has brought new vitality and solutions to the industrial, environmental, and energy sectors.

In the vast industrial production system, pyrolysis waste-to-oil machines have become a valuable tool for processing waste plastics, tires, and oil sludge. Pyrolysis equipment can convert these wastes into useful fuel oil. This not only solves the waste disposal challenge for businesses, but also opens up a new resource acquisition channel.

In the environmental protection sector, pyrolysis waste to oil machines are a true green guardian of the environment. They process municipal solid waste, converting it into economically valuable fuel oil and carbon black while effectively reducing environmental pollution. Furthermore, the pyrolysis waste to energy process purifies the exhaust gas before it meets emission standards, ensuring harmless waste treatment.

In the energy sector, waste to oil machines have made a significant contribution to easing energy shortages. The process of converting waste into fuel is effectively a form of energy recovery. Pyrolysis oil can be used as a fuel in industrial boilers, power plants, and transportation. Pyrolysis waste reduces dependence on traditional fossil fuels for energy, mitigating energy supply risks.

Application Scenarios for Pyrolysis Waste

Pyrolysis technology is highly adaptable and can process most types of organic solid waste. Currently, pyrolysis technology has been widely applied in plastics, rubber, agricultural and forestry waste, and medical waste. It has become a key solution for “waste resource conversion” across various industries.

Plastic Waste Pyrolysis to Fuel

Plastic waste, due to its resistance to natural degradation, has long been a major source of “white pollution.” Traditional landfill disposal occupies land and easily causes soil contamination, while recycling faces the challenges of difficult sorting and high purity requirements. Pyrolysis technology provides a new solution for plastic waste treatment.

A German plastic pyrolysis plant processes 15,000 tons of waste plastic annually, producing 12,000 tons of refined pyrolysis oil. This reduces CO2 emissions by 18,000 tons annually and avoids soil contamination caused by plastic landfills.

Rubber Waste Pyrolysis to Oil

Used tires are another typical difficult-to-treat waste type. Traditional landfill disposal can easily lead to “black pollution,” and harmful substances in tires can leach into groundwater. Pyrolysis technology reduces the volume of scrap tires and recovers high-value resources.

A waste tire pyrolysis project in China processes 100,000 tons of scrap tires annually. It produces 42,000 tons of pyrolysis oil, 33,000 tons of recycled carbon black, and 12,000 tons of steel wire. The use of recycled carbon black reduces the rubber industry’s reliance on virgin carbon black. It also reduces tire production costs, creating a win-win situation for both environmental protection and economics.

Pyrolysis Biomass Waste to Biochar

Traditional methods for disposing of agricultural and forestry waste involve incineration or random dumping, which not only wastes resources but also contributes to air pollution. Biomass pyrolysis equipment converts agricultural and forestry waste into “energy + fertilizer,” providing technical support for rural revitalization.

The primary product of pyrolysis waste biomass is biochar, a high-quality soil conditioner that can also be used to make activated carbon and slow-release fertilizer carriers.

Pyrolysis of Medical Waste

Medical waste contains pathogens and toxic and hazardous substances. Traditional medical waste treatment relies primarily on incineration, but this process can generate secondary pollutants such as dioxins and heavy metal fly ash. Pyrolysis technology, thanks to its high-temperature decomposition in an oxygen-free environment, has become a “safe option” for medical waste treatment.

The core goal of medical waste pyrolysis is to render it harmless. High temperatures completely kill pathogens in the waste, while the oxygen-free environment prevents the formation of dioxins. Furthermore, the small amount of solid residue produced after pyrolysis can be safely landfilled after testing and meeting standards, achieving a volume reduction rate of over 90%. Furthermore, the pyrolysis gas generated by medical waste pyrolysis can be used to heat the pyrolysis reactor itself, achieving an energy cycle.

Benefits of Pyrolysis Waste to Energy

Waste Reduction and Resource Recycling: Pyrolysis plants can convert up to 90% of organic waste into energy products. This significantly reduces landfill pressure and is one of the ultimate practical applications of the “Zero Waste City” concept.

Energy Source and Security: Pyrolysis oil can be used as an alternative fuel for boilers and kilns. After distillation and refining, it can be used in diesel engines, reducing dependence on external energy sources.

Dual Environmental Benefits: On the one hand, pyrolysis waste avoids the greenhouse effect and leachate pollution caused by landfills. On the other hand, by replacing fossil fuels, it reduces carbon emissions throughout the entire life cycle.

Economic Potential and Industrial Opportunities: With the fluctuation of crude oil prices and the implementation of carbon tax policies, the economic benefits of pyrolysis products are becoming increasingly prominent. It can also catalyze a new waste resource recovery industry chain and create green jobs.