The tire to oil plant is an industrial facility specifically designed to convert waste tires into reusable resources. It plays an increasingly important role in resource recycling and environmental protection.

The tire to oil plant operates on the principle of pyrolysis technology. This is a process that decomposes organic matter into smaller molecules at high temperatures in an oxygen-free or low-oxygen environment.

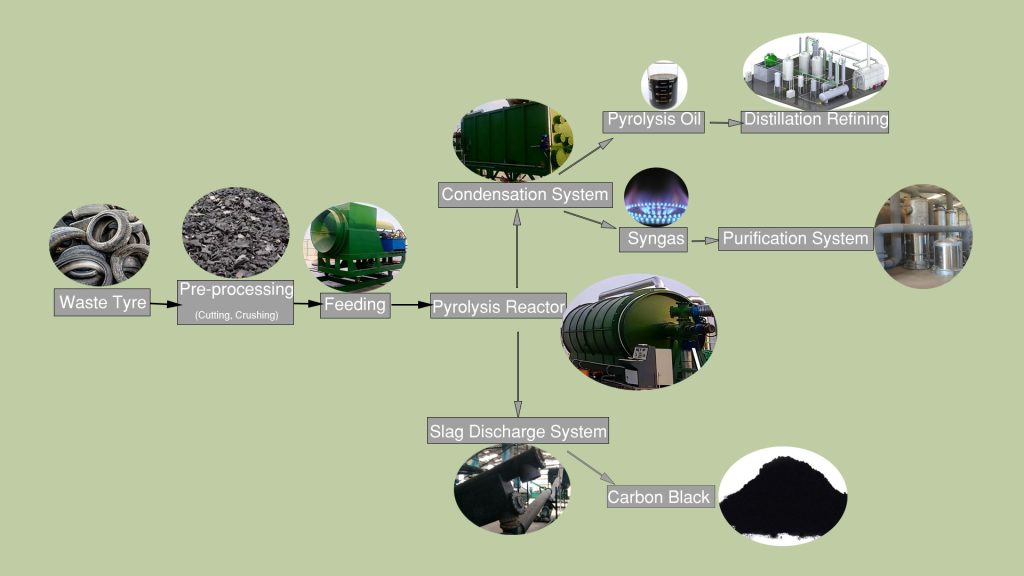

In the tire to oil plant, waste tires are fed into a pyrolysis reactor. Tires are mainly composed of rubber, steel wire, carbon black, and various additives. Rubber, the main organic component, is derived from petrochemical products and undergoes a pyrolysis reaction at high temperatures.

As the temperature inside the pyrolysis reactor gradually rises to a slightly positive-pressure, oxygen-free environment of 280-320°C, the chemical bonds of the high-molecular polymers (such as rubber) in the tires begin to break, gradually decomposing into smaller molecular chains. These smaller molecular chains further react to generate tire oil, gases, and residues.

The resulting oil and gas then enter a condensation unit, where they are cooled and transformed into liquid tire oil, which is collected and stored. The non-condensable gases mainly contain alkanes and alkenes. After purification, it can be reused as fuel in the reactor, achieving energy recycling.

After tyre pyrolysis, the remaining solid residue mainly consists of carbon black and a small amount of incompletely separated steel wire and other impurities. The carbon black, after further processing, such as magnetic separation to remove the steel wire and grinding, can be reused in the rubber industry as a reinforcing agent and filler. The steel wire can be recycled and reprocessed for manufacturing other metal products.

Benefits of Tire to Oil Plant

The value of tire to oil pyrolysis plant lies in the combination of economic and environmental benefits.

Tire to Oil Plant, as key facilities for the resource utilization of waste tires, play an irreplaceable role in resource recycling and environmental protection. It effectively solves the environmental pollution problems caused by waste tires. Furthermore, by converting waste tires into usable resources (tire oil and carbon black), the pyrolysis plant achieve resource recycling.

The profitability of tire to oil pyrolysis projects is directly linked to processing scale, oil yield, and downstream markets. Besides reducing fuel costs through internal use, the sale of pyrolysis oil generates substantial profits. Furthermore, sales revenue from carbon black and steel wire also contributes to profits.

Compared to landfilling and illegal incineration, pyrolysis technology achieves resource recycling, reducing the consumption of virgin petroleum and carbon black. Modern tire to oil plant is equipped with comprehensive exhaust gas purification, wastewater recycling, and safety systems. This ensures that the entire tire oil production process complies with environmental regulations.

Development Prospects of Tire Pyrolysis Industry

Currently, a policy paradigm shift is underway globally. This will be a key force driving the tire pyrolysis industry from the periphery to the mainstream.

From Energy Recovery to Circular Feedstock: EU regulations clearly state that using pyrolysis oil as a feedstock for the production of new plastics or chemicals is considered advanced recycling. If it is only burned as fuel, it is classified as energy recovery, with lower value. This is driving European operators to channel pyrolysis oil into the chemical industry chain.

Manufacturing Identity and the Carbon Credit Market: More than 24 US states have redefined pyrolysis as manufacturing rather than waste disposal, simplifying project approval. More importantly, market mechanisms such as California’s Low Carbon Fuel Standard (LCFS) create trading credits for low-carbon intensity fuels. Since the carbon in the natural rubber (biomass) portion of tires is considered carbon neutral, pyrolysis oil fuel may obtain a better carbon intensity value, thus generating additional credit gains.

Under the global trend of sustainable development, pyrolysis plants are expected to become a key pillar industry in the resource recycling sector. Tire to oil plant will make a greater contribution to addressing global resource shortages and environmental pollution, helping us move towards a greener, lower-carbon, and more sustainable future.