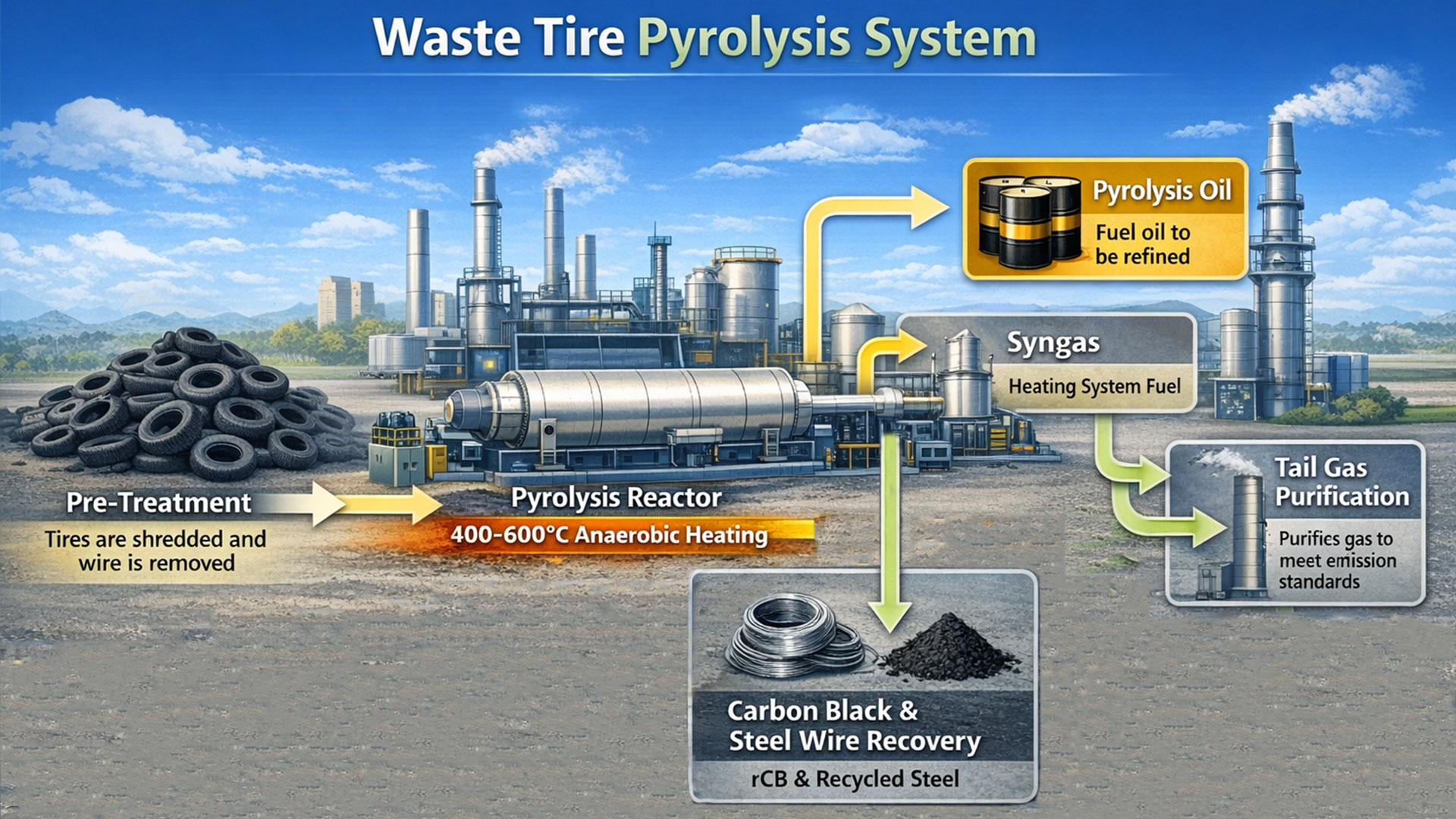

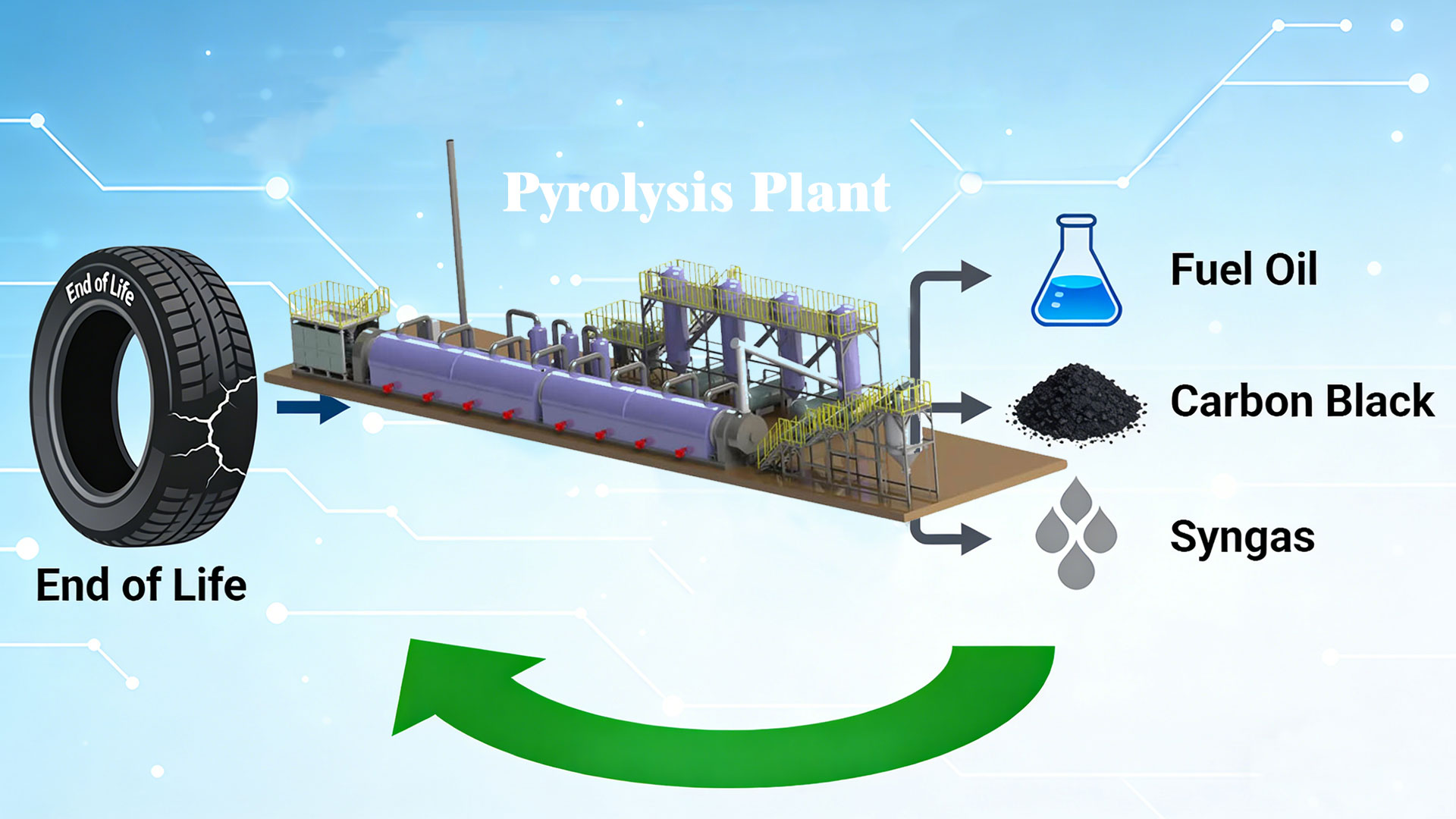

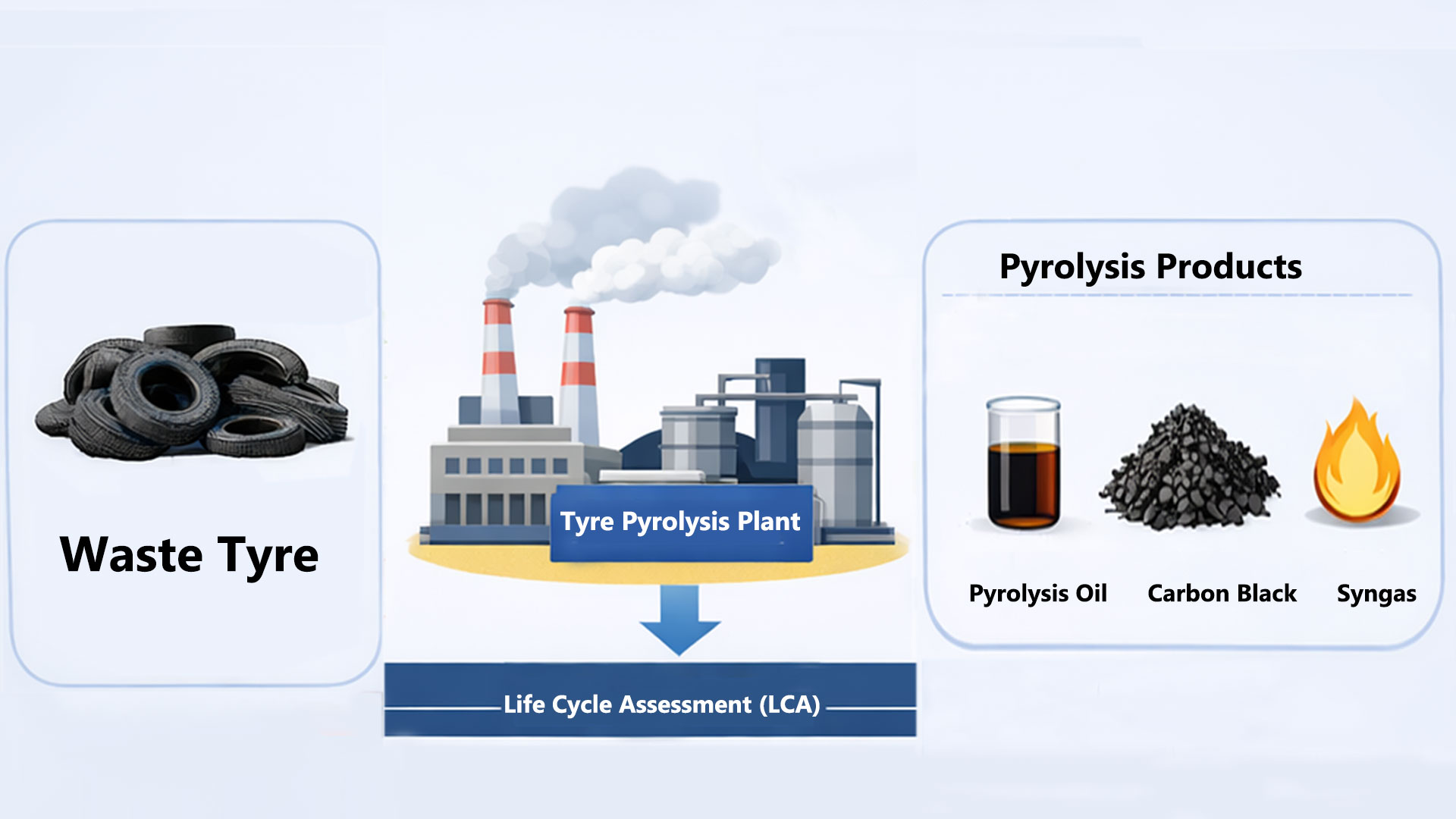

Waste Tire Pyrolysis System

The waste tire pyrolysis system, as a solution to the challenging problem of waste tire disposal, enables the resource utilization of waste tires. Through high-temperature decomposition, waste tires can be converted into various high-value products such as carbon black, pyrolysis oil, synthesis gas, and steel wire. Carbon black can be used in the reprocessing of … Read more