The continuous waste tyre pyrolysis oil production line is used to recycle waste tyres. It can convert waste tires into pyrolysis oil, carbon black, steel wire and synthesis gas.

The fully automatic tyre pyrolysis plant can achieve large-scale waste tire disposal under the premise of safe, environmentally friendly, continuous and stable operation. Emerging markets and application areas will also bring broad development space for tire pyrolysis oil.

In the field of new energy vehicles, with the popularization of electric vehicles, the amount of waste tires will also increase accordingly, providing a richer source of raw materials for the tire pyrolysis oil industry.

In the field of aerospace, tyre pyrolysis oil can be used to produce aviation fuel after further refining and modification to meet the aviation industry’s demand for high-performance fuel.

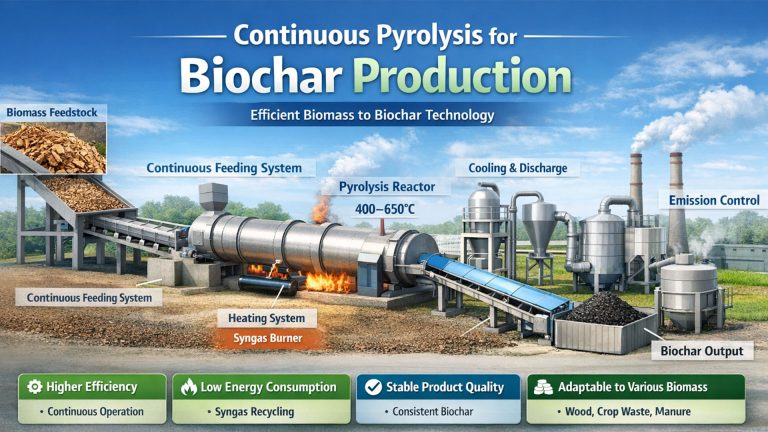

The fully continuous waste tyre pyrolysis oil production line mainly includes a feeding system, a pyrolysis system, an oil and gas condensation system, a non-condensable combustible gas purification system, a discharging system, a flue gas purification system, a circulating water cooling system and an intelligent control system.

How is Tyre Pyrolysis Oil Produced?

Tyre pyrolysis oil (TPO) is a liquid product produced by high-temperature pyrolysis of waste tyres under anaerobic or anoxic conditions. It is one of the core products of waste tyre pyrolysis process.

The entire fully continuous tyre pyrolysis process does not produce wastewater, waste gas or waste residue, achieving 100% utilization of waste tire resources.

The feeding system can quantitatively and continuously deliver the crushed waste tires to the pyrolysis reactor. The material completes the pyrolysis reaction in a pyrolysis reactor with a slight negative pressure, set temperature, oxygen-free or oxygen-deficient.

After the oil and gas obtained by tyre pyrolysis are cooled and separated, the tyre pyrolysis oil is pumped to the tank area. Crude tire pyrolysis oil can significantly improve the quality of fuel oil through waste oil distillation plant and be converted into diesel or gasoline.

The non-condensable combustible gas enters the subsequent purification system. After purification, the non-condensable combustible gas is transported to the continuous heating device for combustion to provide heat for the pyrolysis of waste tires. The solid product obtained by the pyrolysis of tires is cooled to obtain carbon black.

The recycled waste flue gas is cooled and purified and discharged to the standard. The water pump delivers circulating water to each process equipment for heat exchange with the tire pyrolysis product. The warm water after heat exchange returns to the cooling tower for cooling and recycling.

The control system automatically controls the equipment according to the process requirements, and has functions such as data collection, calculation, recording and safety warning to ensure the safe, stable and continuous operation of the tire pyrolysis oil production line.

Tire Pyrolysis Oil Market

In recent years, the global tire pyrolysis oil market has shown a steady growth trend. According to statistics and forecasts from QYResearch, the global tyre pyrolysis oil market sales reached US$44 million in 2023, and is expected to reach US$89 million in 2030, with a compound annual growth rate (CAGR) of 10.5% during 2024-2030.

In terms of regional distribution, North America, Asia Pacific and Europe are the main markets for tire pyrolysis oil in the world.

Among them, North America has the largest market size of tyre pyrolysis oil, accounting for about 39% in 2023. As the main economy in North America, the United States has a huge number of cars and a complete waste tire recycling system. It provides sufficient raw materials and a broad market space for the development of the tire pyrolysis oil industry.

The Asia-Pacific region follows closely, tyre pyrolysis oil market accounting for about 31%, and the growth rate is relatively fast. In countries such as China and India, as the amount of waste tires generated increases sharply, the market demand for tire pyrolysis oil is also growing. At the same time, the government’s strong support for the environmental protection industry has introduced a series of preferential policies and subsidy measures, further promoting the development of the tire pyrolysis oil market in the Asia-Pacific region.

The European tyre pyrolysis oil market accounts for about 22%, and the region attaches great importance to environmental protection and sustainable development. This has prompted companies to actively explore ways to recycle waste tires. As an environmentally friendly product, tire pyrolysis oil has received widespread attention and application in the European market.

The global tire pyrolysis oil market is highly competitive, and a diversified competitive landscape has been formed. Major companies include Reoil, Bolder Industries, Green Distillation Technologies, ENRESTEC and MODUL LTD. These companies have their own advantages in technology research and development, production scale, product quality and market channels, leading the development direction of the industry.

In addition to the above companies, there are a large number of small and medium-sized enterprises in the market. Although these companies are small in scale, they have also occupied a place in the market with flexible business strategies and deep cultivation of market segments.

Custom Tire Pyrolysis Plant Manufacturer

Mingjie Group is a professional pyrolysis plant manufacturer, we will continue to develop in the direction of improving the quality of tyre pyrolysis oil and reducing the cost of tyre pyrolysis equipment.

Mingjie Group mainly provides customized solutions and equipment for tire pyrolysis. Our batch pyrolysis plant can help small and medium-sized enterprises process 6-15T/D of waste tires. The fully continuous pyrolysis plant has a large processing capacity, which can process 35-40T tires and 30T plastics per day.