In May 2018, Mingjie Group completed the installation of two MJL-15 tyre recycling pyrolysis plants for sale to Lebanon. The MJL-15 semi-continuous pyrolysis equipment is equipped with an automatic feeding system. Feeding can be done at high temperature, no need to wait reactor temperature cooling down. Each can process 15-16 tons of waste tires per day.

Waste pyrolysis equipment is the best choice to completely solve the black pollution of waste tires. The tire pyrolysis plant can pyrolyze waste tires and completely transform them from solid state to liquid and gas state. It makes full use of the entire tire, “turning waste into treasure”.

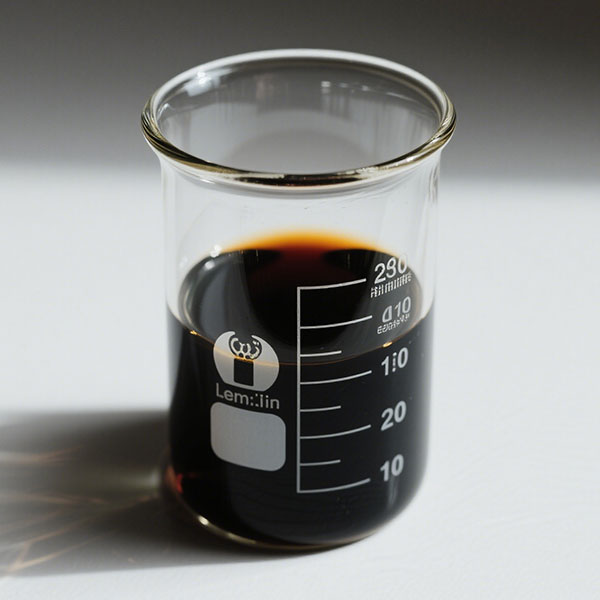

The final products of waste tire pyrolysis are fuel oil, carbon black, synthesis gas and steel wire.

The practice of tire pyrolysis project has proved that each ton of waste tire can produce about 40-50% fuel oil, about 5-10% synthesis gas, about 300 kg carbon black, and more than 160-200 kg steel wire.

Semi-continuous Tyre Recycling Pyrolysis Plant for Sale

The Mingjie semi-continuous pyrolysis plant for sale combines some features of batch and fully automatic pyrolysis plant. It is particularly suitable for scenarios with diverse materials, moderate scale, and both economic and environmental protection.

Semi-continuous tyre recycling pyrolysis plant achieves a balance between efficiency, cost and flexibility through the mode of continuous feeding and staged pyrolysis.

Advantages of Semi-continuous Pyrolysis Equipment

Semi-continuous tyre recycling pyrolysis plants are suitable for small and medium-sized solid waste treatment projects, resource utilization of plastic-rubber-biomass mixtures, and rapid harmless treatment of hazardous waste.

Efficient Processing and Capacity Balance

Semi-continuous tyre recycling pyrolysis plant can achieve periodic continuous feeding. This avoids the completely discontinuous operation of batch pyrolysis plant “feeding-pyrolysis-discharging”, and improves the processing volume per unit time.

Compared with fully continuous plant, it has stronger adaptability to materials. It is suitable for processing wastes with complex components and requiring phased adjustment of process parameters (such as plastics, rubber, and biomass mixtures).

Semi-continuous tyre recycling pyrolysis plant can not only meet the production capacity requirements of small and medium-sized projects, but also flexibly adapt to different processing scales by adjusting the operating cycle.

Process Flexibility and Adaptability

Semi-continuous tyre recycling pyrolysis plant can process a variety of waste types (such as waste plastics, waste tires, medical waste, etc.). It can achieve efficient conversion of different materials by adjusting parameters such as pyrolysis temperature and residence time.

Cost-effectiveness and Energy Saving

Compared with fully continuous pyrolysis plant, the mechanical structure of semi-continuous equipment (such as feeding system and furnace body sealing) is simpler. The initial investment can be reduced by 20%-40%, which is suitable for small and medium-sized enterprises.

The phased operation mode can start and stop the equipment according to production needs, avoiding the energy waste of long-term full-load operation of fully continuous equipment.

It adopts a heat storage design or waste heat recovery system to reduce heat loss. For example, the waste heat of the furnace after pyrolysis can be used to preheat the next batch of materials, reducing energy consumption by about 15%-25%.

Easy Operation and Maintenance

Equipped with a semi-automatic control system to reduce the intensity of manual operation. At the same time, it avoids the complexity and failure risk of the fully automated system.

The modular design allows key components (such as feeders and pyrolysis reactors) to be quickly replaced, reducing downtime and improving equipment utilization.

Controllable Safety Risks

Compared with the high-pressure and high-temperature continuous operation of fully continuous plant, the operating pressure of semi-continuous equipment is lower. There are also pressure relief and cooling stages between batches to reduce the risk of safety accidents, such as explosions and leaks. Semi-continuous pyrolysis plants are particularly suitable for processing materials containing volatile components (such as waste oil sludge).

Conclusion

Semi-continuous tyre recycling pyrolysis plant has unique advantages in processing efficiency, flexibility and cost control. With the increasing demand for small and medium-scale waste treatment in the circular economy, semi-continuous pyrolysis plants are expected to be more widely used in the field of solid waste resource utilization.