Waste tire to oil pyrolysis plant has become an engineered solution that combines resource recycling and economic benefits. Facing the pressure of managing billions of waste tires globally each year, pyrolysis technology represents a way to transform waste into valuable resources. Tire pyrolysis plant not only recovers high-value pyrolysis products, enabling resource regeneration, but also addresses environmental pollution problems.

With the continuous strengthening of global environmental awareness and strong support from relevant policies, the market demand for waste tire to oil pyrolysis plant will continue to grow. Many countries and regions have introduced strict environmental regulations to restrict the landfilling and incineration of waste tires, encouraging the use of environmentally friendly and efficient pyrolysis technology for processing.

The European Union has formulated relevant waste management policies, requiring member states to increase the recycling rate of waste tires. The proportion of waste tire to oil pyrolysis is expected to increase gradually.

Some local governments provide financial subsidies to newly established waste tire to oil pyrolysis plants, reducing the investment costs for businesses. They also offer preferential policies (tax reductions) to companies engaged in waste tire pyrolysis, improving their profitability.

Waste Tire to Oil Pyrolysis Projects in the World

Bridgestone is building a new waste tire pyrolysis plant in Seki City, Gifu Prefecture, Japan. The plant, covering 15,000 square meters, will process 7,500 tons of waste tires annually and is expected to be completed and operational in 2027. As a key component of Bridgestone’s “EVERTIRE INITIATIVE” strategy, this pilot project aims to transform waste tires into recyclable resources through precision pyrolysis technology.

By precisely controlling key parameters such as heating temperature and time, it efficiently recovers decomposition oil and reclaimed carbon black from waste tires. Ultimately, these recovered resources will be recycled as raw materials for tires, providing a groundbreaking technological solution for the low-carbon transformation of the tire industry.

On September 23, 2025, Enviro, a globally renowned company specializing in waste tire recycling, announced that the construction of its waste tire pyrolysis plant in Uddevalla, Sweden, is progressing smoothly. The plant will be able to process 34,500 tons of waste tires annually, equivalent to 40% of the total waste tires generated in Sweden each year. This waste tire to oil pyrolysis plant offers a new solution to the global problem of black pollution.

The tyre pyrolysis plant converts waste tires into four high-value products: approximately 40% pyrolysis oil, 30% recovered carbon black, 20% steel wire, and 10% combustible gas. The products from the pyrolysis process can be used to support the sustainable raw material commitments of tire manufacturers. Environmental organizations estimate that processing 10,000 tons of waste tires can reduce carbon emissions by approximately 30,000 tons.

How to Plan a Waste Tire Pyrolysis Project?

Plant Site Selection and Layout

The waste tire to oil pyrolysis project needs to be located near the supply chain for waste tire raw materials and product applications.

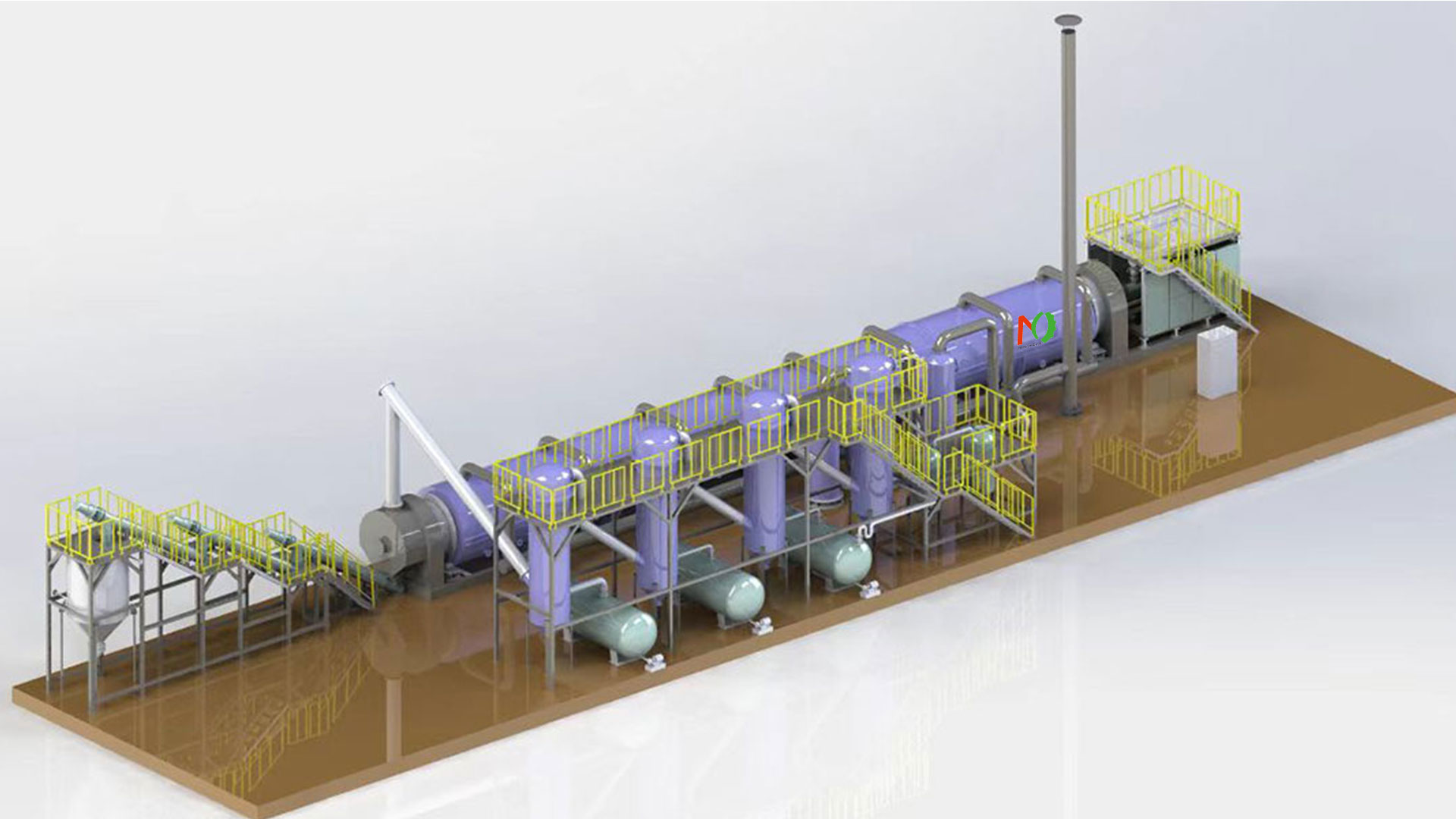

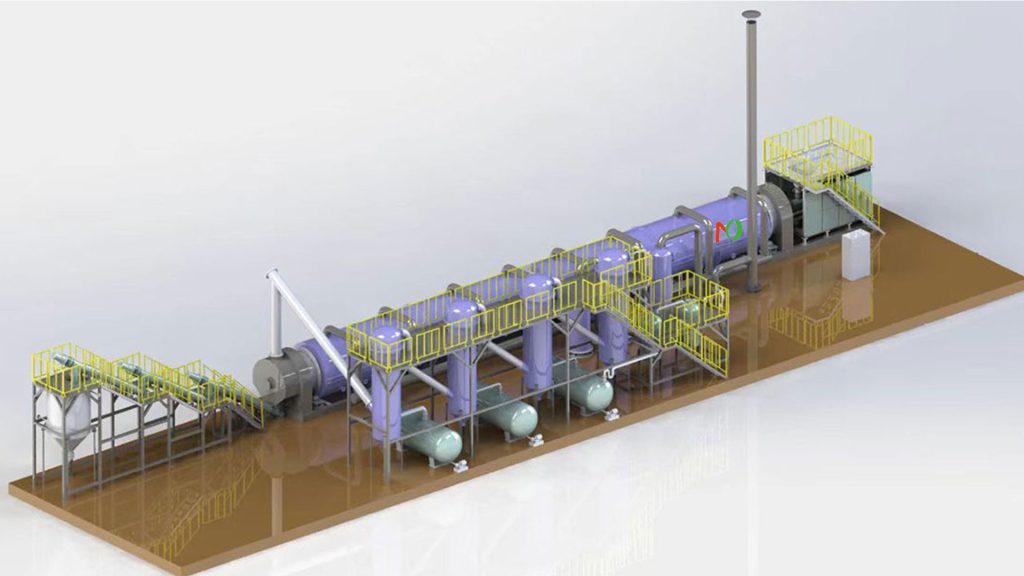

The layout includes a raw material storage area, pyrolysis workshop, carbon black deep processing workshop, raw material pretreatment workshop, carbon black finished product warehouse, gas supply area, power distribution room, oil tank area, desulfurization and denitrification area, circulating water system, emergency fire fighting area, fire fighting tank area, loading area, sewage treatment area, gas storage device area, air combustion area, emission area, and office area.

The pretreatment workshop should be located near the raw material storage area and should be large enough to meet the required production capacity.

Processing Scale and Benefits

The processing scale is determined based on the amount of waste tires available at the pre-selected site, and further refined based on funding and market demand.

- Raw Material Supply: We maintain a reserve of raw materials sufficient for more than two months of operation.

- Equipment Configuration: The pretreatment equipment has high capacity and low energy consumption. The continuous waste tyre pyrolysis plant has a high oil yield and excellent oil quality. The carbon black deep processing equipment and testing instruments are comprehensive, and each stage features a high degree of safety and production automation control. Outdoor utilities are fully equipped.

- Operating Cost Control: Hire professionals to control operating costs.