In recent years, the global waste tyre pyrolysis industry has shown a booming trend. In Europe, waste tyre pyrolysis plant is rapidly rising and gradually becoming one of the important ways to treat waste tires. The tire recycling market size in Europe reached 3.728 billion US dollars in 2024, accounting for more than 30% of the global total. Among them, waste tyre pyrolysis is one of the fastest-growing sub-sectors.

Europe generates approximately 3.6 million tons of waste tires each year. Although the proportion of pyrolysis treatment is low, it is growing rapidly.

In 2024, the tyre pyrolysis processing capacity in Europe was approximately 62,400 tons, accounting for only 1.4% of the global total. However, it is planned to increase the annual processing capacity to 672,000 tons in the coming years, accounting for 11% of the global market.

Waste Tires Pyrolysis Recycling Market in Europe

The UK, Germany and France account for over 60% of the European waste tire recycling market. Enterprises such as Circtec, Pyrum and Enviro lead the technological research and development and large-scale production.

Poland ReOil processes 60,000 tons annually and Germany’s CRR processes 20,000 tons annually. They expanded rapidly relying on lower raw material costs and policy subsidies.

BB&G Recycling in Portugal processes 16,000 tons annually. It provides Bridgestone with pyrolysis oil for tyre recycling production.

Pyrolysis Project Support

The goal of the circular economy: The EU’s Circular Economy Action Plan requires that the recycling rate of used tires reach 85% by 2030 and promotes enterprises to use low-carbon raw materials through the Carbon Border Adjustment Mechanism (CBAM). Pyrolysis carbon black (rCB) is classified as a “highly sustainable industry” in the EU classification system, and each ton of rCB can reduce carbon dioxide emissions by 3.1 tons. It attracts tire enterprises to purchase pyrolysis plants to meet sustainable production goals.

Technological commercialization breakthrough: The EU’s 4.8 billion euro development fund supports pyrolysis projects, promoting the popularization of pyrolysis systems throughout Europe.

Emerging market demand: The EU’s ReFuelEU plan requires that SAF (Sustainable Aviation fuel) account for 2% of jet fuel starting from 2025. Waste tyre pyrolysis oil can be used as SAF raw material, and the UK has taken the lead in using it in the aviation industry.

Pyrolysis plant for Sale

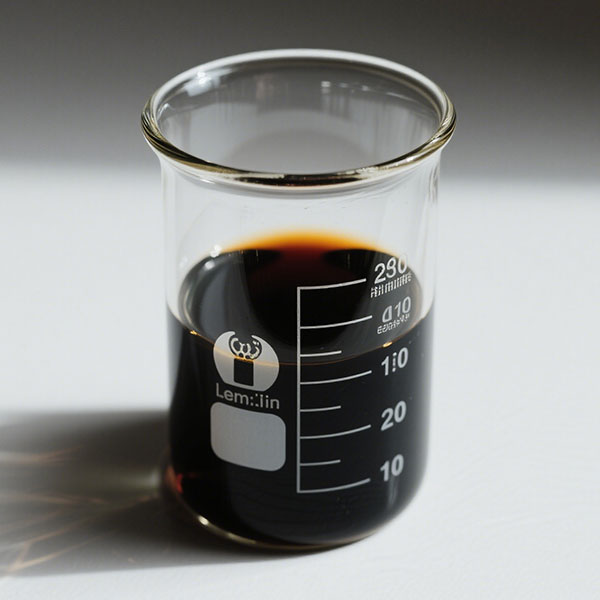

Mingjie pyrolysis plants are key equipment for the resourceful reuse of carbon black from waste tires. The waste tyre pyrolysis equipment pyrolyzes waste tires under specific temperature, anaerobic or anoxic conditions. The pyrolysis products mainly include pyrolysis oil, synthesis gas, carbon black and steel wire.

Our pyrolysis plant is designed in accordance with international standards and has a powerful processing capacity. The pyrolysis system includes a pyrolysis reactor, a condensation system, a heating system and a purification system. It has positive significance for improving work efficiency, reducing energy consumption and protecting the ecological environment.

Mingjie pyrolysis plants are divided into Portable Small Pyrolysis Plant, Batch Pyrolysis Plan, Semi-continuous Pyrolysis Plant and Fully Automatic Pyrolysis Plant according to different operating methods and capacities. They can be used to process waste tires, plastics, sludge, municipal solid waste, medical waste, etc. And customers can choose different models according to the size of the raw materials and production requirements.

Challenge of Waste Tyre Pyrolysis Industry

The waste tyre pyrolysis industry faces many challenges in its development.

First, the high technical cost is one of the important factors that restrict its large-scale promotion. The investment in tire pyrolysis plant is large, and the operation and maintenance costs are relatively high. This makes many companies discouraged when they get involved in this field.

Taking a medium-sized tyre pyrolysis production line as an example, the pyrolysis equipment cost may be as high as tens of millions of dollars. Coupled with the subsequent energy consumption, pyrolysis equipment maintenance and other costs, the operating cost cannot be underestimated.

Secondly, the recycling system of waste tires is not yet perfect. At present, the recycling channels of waste tires are relatively scattered and lack effective organization and management. This leads to low recycling efficiency of waste tires and increased recycling costs. Many waste tires are scattered all over the country, making it difficult to collect and transport them in a centralized manner. This affects the stability of raw material supply in the pyrolysis industry.

The lack of people’s understanding and acceptance of waste tyre pyrolysis technology has also hindered the development of the industry to a certain extent. Some people have doubts about the quality and safety of pyrolysis products and lack understanding of the environmental protection of pyrolysis technology. This makes pyrolysis products face certain difficulties in the market promotion process.