The entire tire lifecycle consists of three key steps: tire production, waste tire collection, and waste tire recycling. Waste tyre recycling plants prioritize waste tires based on quality, from high to low. High-quality tires are directly retreaded, medium-quality tires are used to produce recycled rubber and rubber powder, and low-quality tires are pyrolyzed to produce pyrolysis oil, carbon black, and other products. This maximizes the value of waste tires and minimizes waste.

Today, the global waste tyre recycling industry is becoming more mature. It is effectively promoting the development of the green economy and moving towards a more sustainable and efficient direction.

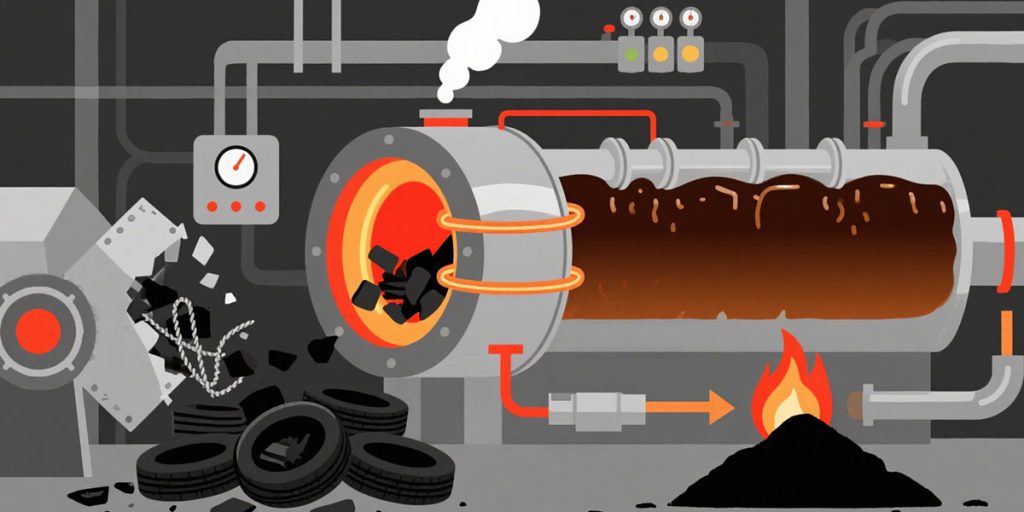

The waste tire pyrolysis process operates in the absence of oxygen or anoxic conditions, eliminating the production of significant quantities of hazardous gases, such as dioxins. Furthermore, it reduces the need for landfill and incineration of waste plastics, thereby reducing pollution to soil, air, and water sources.

Waste Tyre Recycling Market

The global waste tyre recycling market is home to a number of leading companies. In overseas markets, major players include Michelin Group, Genan Group, and Bridgestone.

In 2024, the global waste tire generation will be about 40 million tons, the recycled volume will be about 30 million tons, and the recycling rate will be about 75%.

Downstream demand for scrap tire recycling products continues to grow. These products are mainly concentrated in traditional application areas such as construction and transportation, especially for recycled rubber, rubber pellets/powder, and pyrolysis oil.

The primary challenge facing the waste tyre recycling pyrolysis industry lies in the upstream raw material supply. As waste tires are a core raw material, their collection faces fierce competition from other applications, such as tire retreading, recycled rubber, and rubber powder.

The downstream consumption of the waste tire pyrolysis recycling industry chain mainly involves two major products: pyrolysis oil and carbon black. Pyrolysis oil and carbon black are widely used in the fuel oil market and recycled carbon black.

Tyre Pyrolysis Recycling Plant

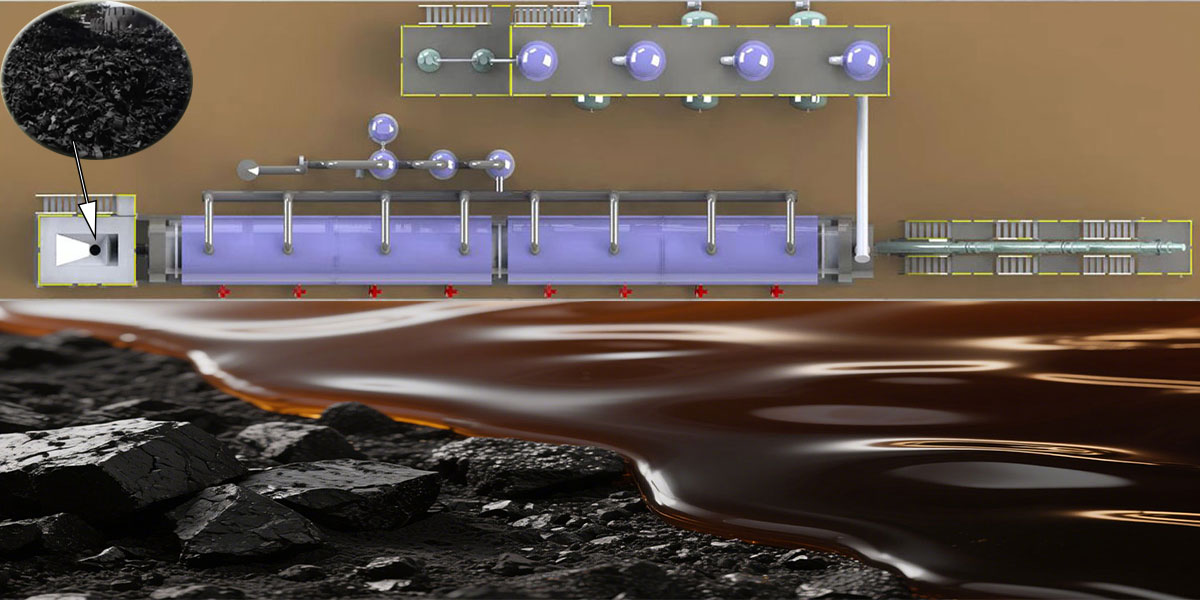

Tyre pyrolysis recycling plant offers a sustainable and profitable solution for waste tire disposal. Pyrolysis plant converts waste tires into pyrolysis oil, carbon black, syngas and steel wire. It achieves resource recycling and improves resource utilization.

Tyre pyrolysis recycling plants are booming globally. According to market research, the number of tire pyrolysis recycling plants has grown at an annual rate of approximately 10% over the past few years, particularly in developed countries and regions such as the United States, Europe, and Japan.

Due to a high level of awareness of environmental protection and resource recycling, the scrap tire processing market is relatively mature, leading to the rapid development of tyre pyrolysis recycling plants.

Governments around the world have introduced policies to strongly support the development of tire pyrolysis recycling plants.

The European Union has established strict waste management regulations, requiring member states to increase the recycling rate of scrap tires. Tyre pyrolysis recycling, as a key resource utilization method, has been actively promoted.

The US government, through tax incentives and subsidies, encourages businesses to invest in tire pyrolysis recycling plants, promoting the resource utilization of scrap tires.

Mingjie batch and continuous tyre pyrolysis plant are both mature and generally meet current regulations and market requirements.

Continuous pyrolysis plant enables continuous feeding and discharging of waste tires, reduces downtime and energy consumption during the production process. It also enhances the stability and controllability of the waste tire pyrolysis reaction, resulting in more uniform and stable pyrolysis product quality.

The generated pyrolysis gas is directly recycled and used to heat the pyrolysis reactor, replacing external fuels (such as natural gas or coal).

In terms of post-processing technology for tire pyrolysis products, Mingjie pyrolysis oil distillation plant further distills and refines the pyrolysis oil, increasing its value.