The waste tyre to oil plant have become key technological equipment for solving the challenges of solid waste and hazardous waste treatment. Because of its core advantages of reduction, harmlessness, and resource utilization. Tyre pyrolysis plant provides efficient and feasible solutions for sustainable waste management systems, and the market is experiencing strong growth.

Globally, over 1.5 billion waste tires are generated annually, the waste tyre to oil plant creates an increasingly urgent need for sustainable treatment solutions. Driven by industrial heating and alternative fuel applications, global demand for tire pyrolysis oil increased by 17% between 2022 and 2024.

The global waste tyre pyrolysis plant market size was US$101.72 million in 2025. The market size is projected to reach US$112.61 million by 2026 and US$281.1 million by 2035, exhibiting a CAGR of 10.7% during the forecast period.

Global Tire Pyrolysis Plants in Operation in 2024

North America

In 2024, North America’s tire pyrolysis capacity accounted for approximately 74% of the total capacity in the United States. According to statistics, the US has over 220 operational waste tyre to oil plants, processing approximately 2.8 million tons of waste tires annually. Canada also contributed approximately 30 operational tire pyrolysis plants. These pyrolysis plants primarily produce alternative fuels for heavy industry, consuming approximately 450,000 tons of tire-derived oil during the same period.

Europe

In 2024, over 300 tire pyrolysis plants were in operation. Germany alone had over 85 plants, recycling approximately 700,000 tons of tires annually. France, Spain, and the UK together accounted for nearly 40% of the total number of waste tyre to oil plants in Europe. Between 2022 and 2024, investment in continuous pyrolysis technology in Europe increased by 19%, and the average recycling rate improved by 11%. The use of recycled carbon black also increased significantly.

Asia Pacific

The Asia Pacific region had over 1,600 tire pyrolysis units built by 2024. China had over 950 units, processing approximately 8 million tons of waste tires annually. India followed closely, adding over 450 units between 2022 and 2024, a growth of 20%. Thailand, Vietnam, and Indonesia together built 180 waste tyre to oil plants during the same period.

Middle East and Africa

In the Middle East and Africa, emerging investments have driven the operation of over 80 waste tyre to oil plants by 2024. South Africa dominates the African market with 35 plants, while the UAE and Saudi Arabia lead in the Middle East. The region generated over 2.5 million tons of waste tires in 2023, creating an urgent need for recycling solutions.

Continuous Waste Tyre to Oil Plant

The waste tyre to oil plant market is undergoing significant technological innovation. By 2024, over 30% of new plants will integrate automated systems. In particular, continuous pyrolysis technology is growing at a rate of 18% annually. Compared to batch pyrolysis systems, continuous pyrolysis plants enable uninterrupted operation and achieve a 25% higher fuel recovery rate.

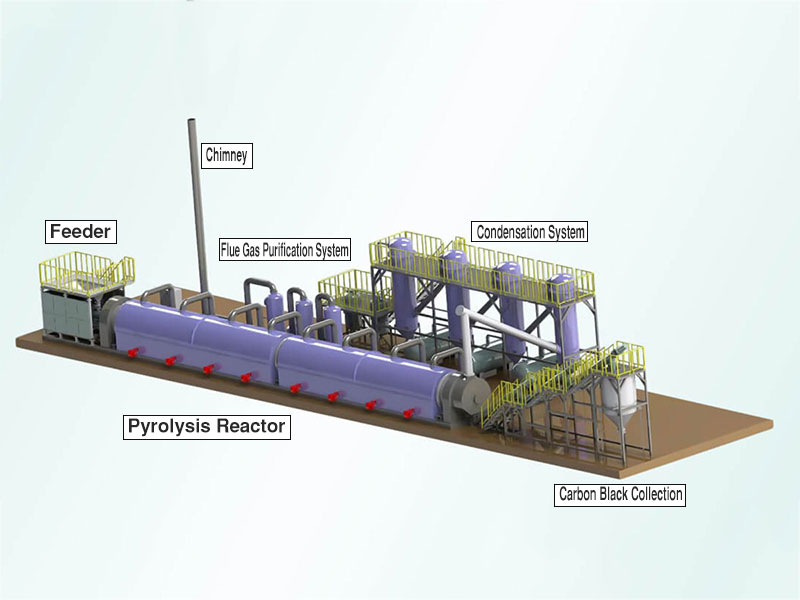

The continuous pyrolysis plant utilizes an industrial assembly line approach. Pre-treated tire shreds are continuously and uniformly fed into a high-temperature reactor through a closed system, undergoing uninterrupted pyrolysis in an oxygen-free environment. The pyrolysis oil and gas, along with the solid residue (carbon black and steel wire), are simultaneously and continuously extracted and discharged, enabling stable 24-hour operation.

Pyrolysis machine, as a low-carbon and environmentally friendly waste treatment technology, has significant industrial value and social significance.

On the one hand, the pyrolysis process enables the resource recovery of waste. It reduces reliance on traditional fossil fuels and lowers carbon emissions during energy production.

On the other hand, pyrolysis machine can effectively treat organic waste, reducing methane gas emissions from landfills. It also avoids the large amount of carbon dioxide emissions generated during incineration, providing strong support for achieving carbon emission reduction targets.