The continuous waste tyre to oil pyrolysis plant demonstrates exceptional environmental performance, making it a green pioneer in the field of waste tire processing. Its pyrolysis process takes place in a completely enclosed system, effectively placing an environmental shield over the entire process. This tightly controls potential pollution within the system. By operating in an oxygen-free or low-oxygen environment, the pyrolysis reaction avoids the large amounts of harmful gases produced by traditional incineration processes.

In terms of environmental performance, continuous pyrolysis equipment is typically equipped with a highly efficient exhaust gas treatment system. Such as desulfurization and denitrification devices, dust collectors, and activated carbon adsorbers.

Relevant research data shows that the emissions of sulfur dioxide and nitrogen oxides from continuous waste tyre to oil pyrolysis plant are reduced by more than 80% compared to traditional incineration methods. The emission of highly toxic substances such as dioxins is almost zero, completely eliminating pollution to the atmosphere at the source.

At the same time, the amount of wastewater and waste residue generated during the pyrolysis process is also very small. After proper treatment, they all meet environmental emission standards, and will not cause pollution to soil and water bodies. This effectively avoids secondary pollution and provides strong protection for the ecological environment.

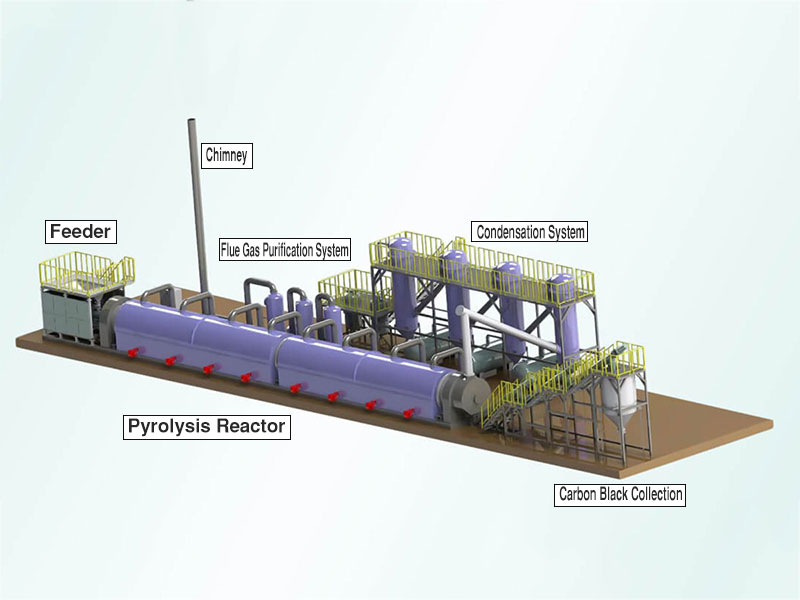

Continuous Waste Tyre to Oil Pyrolysis Plant for Waste Recycling

Continuous pyrolysis technology will play an increasingly important role in waste tire to oil pyrolysis plants. With continuous technological advancements and gradual cost reductions, continuous waste tyre to oil pyrolysis plant will be promoted and applied in more countries and regions. The processing capacity and resource recovery rate of waste tires will be significantly improved.

The high efficiency and stable operation characteristics of continuous pyrolysis technology make it highly competitive in the field of waste tire processing. Continuous waste tyre to oil pyrolysis plant has become the ideal choice for large-scale industrial processing of waste tires.

Industrial Processing of Waste Tires

The continuous waste tyre to oil pyrolysis plant adopts an advanced automatic control system, enabling continuous operation 24/7. It functions as a tire oil production line, continuously processing waste tires.

The MLL-30T continuous waste tyre to oil pyrolysis plant can process 35-40 tons of waste tires per day. Furthermore, the main structure of the continuous pyrolysis equipment is rationally designed and manufactured using high-quality high-temperature and corrosion-resistant materials. This ensures the long-term stable operation of the tire pyrolysis equipment at high temperatures.

In addition, through precise control of the pyrolysis process and the application of waste heat recovery technology, the energy consumption of the continuous pyrolysis equipment has been effectively reduced. Using pyrolysis gas as heating energy not only achieves energy recycling but also reduces external energy consumption. This reduces the energy consumption per ton of waste tires processed by 30%-40%, further improving the economic efficiency and sustainability of continuous tire oil production.

High Resource Recovery Value

In the continuous tire pyrolysis process, waste tires are converted into a variety of products with high economic value.

The yield of fuel oil typically reaches 35% to 45%. This fuel oil can be directly used as industrial fuel for power generation, heating, and other applications. It can also be further refined to produce gasoline, diesel, and other fuel products that meet standards, providing a new resource supplement for the energy sector.

The yield of carbon black is approximately 30% to 35%. Pyrolysis carbon black has high purity and good performance and can be widely used in rubber products, inks, coatings, plastics, and other industries. Recycled carbon black can replace some virgin carbon black, reducing production costs and improving product quality.

In addition, the steel wires in waste tires can be efficiently recovered, with a recovery rate of 10% to 15%. After processing, the recovered steel wires can be reused in steel production, achieving the circular utilization of metal resources.

The synthesis gas produced during the pyrolysis process, such as hydrogen, methane, and ethylene, can be used to meet the energy needs of the pyrolysis reaction itself, and the excess can be used for power generation.