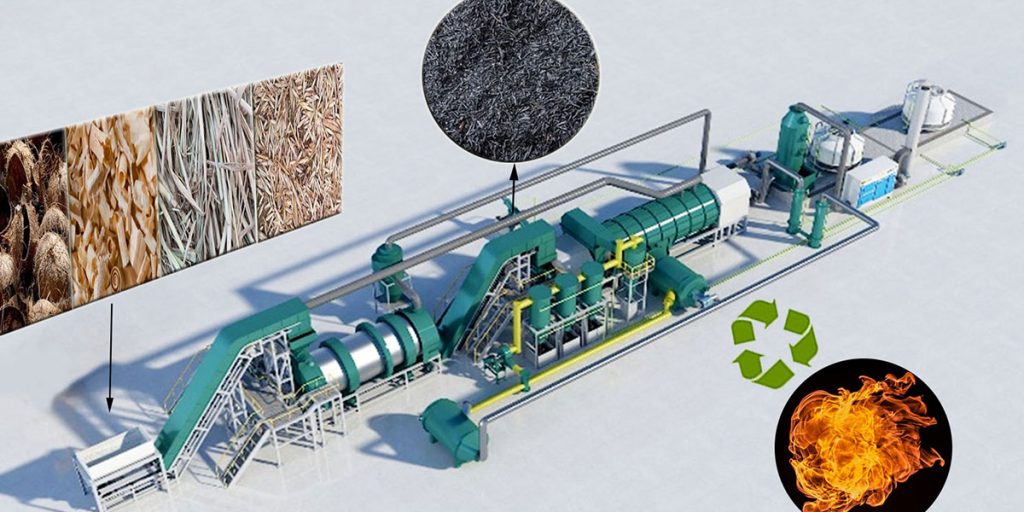

Continuous pyrolysis carbonization equipment for charcoal production is an industrial system that converts biomass into biochar (charcoal). Its core principle is to isolate oxygen and heat to decompose organic matter to produce solid biochar, combustible gas (pyrolysis gas) and liquid by-products (wood tar, wood vinegar).

The continuous biomass carbonization plant solves the problems of high pollution and low efficiency of traditional carbonization through efficient pyrolysis. So carbonization equipment is also called biomass pyrolysis equipment, biochar production equipment, and charcoal making machine.

Continuous pyrolysis carbonization equipment for charcoal making has many significant advantages, which make it stand out in the field of charcoal production and become an ideal choice for achieving efficient, environmentally friendly and economical production.

Advantages of Continuous Pyrolysis Carbonization Equipment

High Efficiency of Charcoal Making

In terms of production efficiency, continuous pyrolysis carbonization equipment for charcoal making has shown excellent performance. Continuous biochar production equipment adopts a continuous production method. It can realize the continuous feeding of raw materials and the continuous discharging of charcoal, which greatly improves production efficiency.

Generally speaking, the heating time of traditional equipment may take several hours. The heating time of continuous pyrolysis carbonization equipment for charcoal making only takes tens of minutes. This enables the equipment to enter the production state faster and improves the utilization rate of the equipment.

Long Service Life

In terms of cost control, continuous pyrolysis carbonization equipment performs well. Although the initial investment of continuous pyrolysis carbonization equipment is relatively high, its long-term operating cost is low. Due to the high production efficiency of biochar and the large output per unit time, the fixed cost allocated to each unit of product is greatly reduced.

In addition, the biomass carbonization plant adopts an automated control system, which reduces the manual operation links and reduces labor costs. The automated control system can accurately control the operating parameters of the equipment, such as temperature, pressure, feed rate, etc. This avoids production accidents and product quality problems caused by manual operation errors. Compared with traditional manually operated equipment, continuous pyrolysis carbonization charcoal making equipment can save about 40% of labor costs.

Moreover, biochar making machine has a long service life and low maintenance cost. Continuous pyrolysis carbonization equipment uses high-quality stainless steel materials and advanced manufacturing processes. It has good wear resistance and corrosion resistance, reducing the number of equipment repairs and the frequency of replacement of parts.

Environmental Protection

From the perspective of environmental protection characteristics, the continuous pyrolysis carbonization plant for charcoal making is a green and environmentally friendly equipment. The continuous carbonization equipment uses an oxygen-free or oxygen-deficient environment to pyrolyze biomass, which greatly reduces the generation of harmful gases.

Compared with the traditional charcoal burning method, the continuous pyrolysis carbonization equipment for charcoal making can significantly reduce the emission of harmful gases such as carbon dioxide, carbon monoxide, and sulfur dioxide.

Relevant data show that when traditional earth kilns burn charcoal, about 1.5 tons of carbon dioxide and 0.2 tons of carbon monoxide are emitted for every ton of charcoal produced. However, for every ton of charcoal produced by a continuous pyrolysis carbonization plant, the carbon dioxide emissions can be reduced to less than 0.5 tons.

At the same time, the biomass carbonization plant is also equipped with an advanced tail gas treatment system. It can purify the tail gas generated during the biomass pyrolysis process to meet environmental emission standards. The tail gas treatment system uses a variety of technologies such as condensation, adsorption, and combustion to effectively remove pollutants such as tar and dust from the tail gas.

Energy Recycling

The continuous biomass pyrolysis plant also realizes the recycling of energy during the production process. The synthetic gas produced by pyrolysis is collected and reused as fuel for heating the equipment. This reduces dependence on external energy and reduces energy consumption. It is estimated that through energy recycling, the continuous pyrolysis carbonization charcoal making equipment can save about 30% of energy costs.

Market of Continuous Pyrolysis Plant

Continuous pyrolysis carbonization equipment for charcoal production, as a key link in the green industry, has huge development potential and broad expansion space.

Countries have introduced strict environmental protection policies to restrict traditional highly polluting charcoal production methods and encourage the use of green and environmentally friendly production technologies and equipment. This makes continuous pyrolysis plant the first choice for many companies and investors with their environmental advantages.

As an important part of renewable energy, biomass energy has received more and more attention. Continuous pyrolysis carbonization plant can convert biomass waste into energy charcoal and combustible gas. It provides a new option for energy supply, and market demand continues to grow.

Continuous Biomass Carbonization Plant Manufacturer

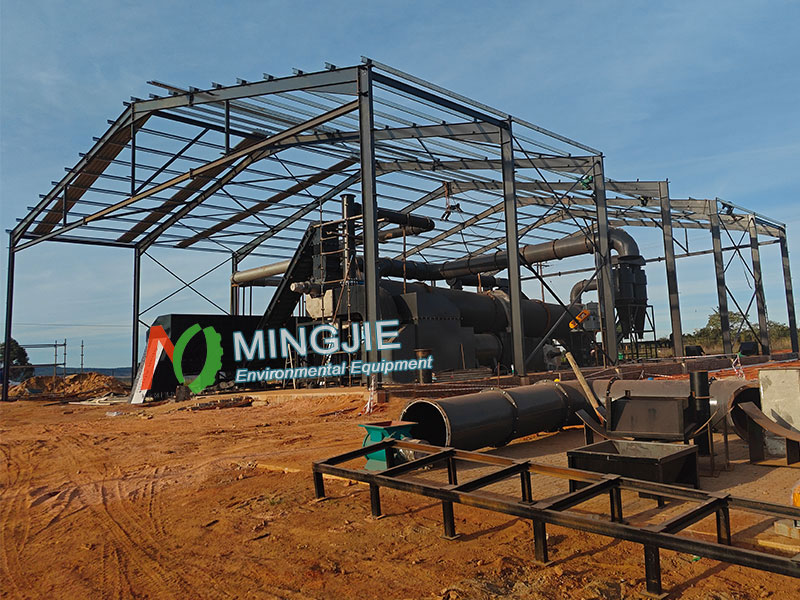

As a professional pyrolysis plant manufacturer, Mingjie Group provides one-stop services for biochar production, including customized solutions, biomass pyrolysis carbonization equipment manufacturing, installation, operation, and after-sales services such as worker training.

The following is a picture of our technical workers installing the carbonization plant in South Africa.

The biochar production line includes a feeding system, a pyrolysis carbonization reactor, a cooling system, a gas purification system, and a PLC control system.

These systems are matched with the core pyrolysis carbonization reactor to ensure the coordinated operation of the entire production system. The automated control system can achieve real-time monitoring and precise control of the production process.