Plastic waste to energy pyrolysis technology is moving from the laboratory to industrial scale. It’s not the sole solution to the plastics crisis, but rather a powerful and indispensable complement to mechanical recycling. Pyrolysis plant can transform plastic waste into a valuable resource, contributing to a sustainable future.

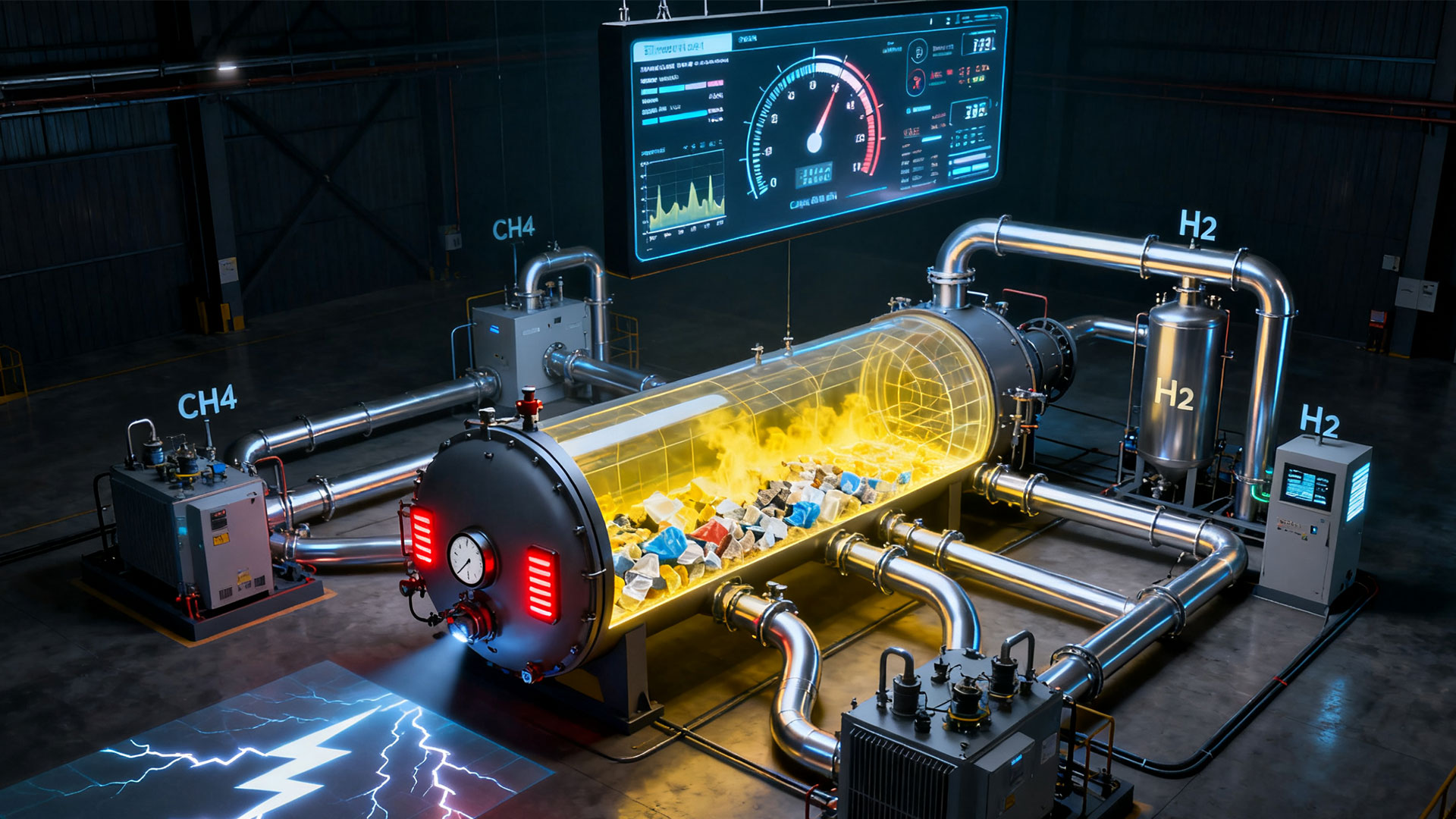

The main products of plastic waste to energy pyrolysis include pyrolysis oil, pyrolysis gas, and solid carbon black. All of these can be used as new energy sources. Plastic pyrolysis oil, a mixture similar to crude oil or diesel, can be used to refine new plastic raw materials or as fuel. Pyrolysis gas, a non-condensable combustible gas (methane and ethylene), is typically recovered for self-heating in the reaction process. Carbon black can be used as a filler or solid fuel.

In recent years, plastic waste to energy pyrolysis technology has garnered widespread attention and rapid development worldwide. Numerous research institutions and enterprises have invested heavily in technology research and development and project implementation, propelling plastic waste pyrolysis technology from the laboratory to industrial application.

Challenges Faced by Plastic Pyrolysis Projects

Although plastic waste to energy pyrolysis projects demonstrate significant potential, they still face numerous significant challenges in their practical implementation and application. These challenges encompass key areas such as energy consumption, costs, raw materials, environmental protection, and regulation.

From an energy and cost perspective, plastic pyrolysis is an energy-intensive process. The pyrolysis reaction requires heating waste plastics to temperatures ranging from 300°C to 900°C. This process consumes significant amounts of energy, much of which relies on external sources.

For example, a typical pyrolysis reactor can require significant amounts of natural gas or other fossil fuels to generate heat for every ton of waste plastic processed. The initial investment required to establish a pyrolysis plant is also substantial. The plastic pyrolysis equipment, supporting pretreatment facilities, and product separation and purification equipment all require specialized design and manufacturing, resulting in significant costs. The subsequent operating costs of a plastic pyrolysis plant are also significant, including energy consumption, equipment maintenance, and personnel management.

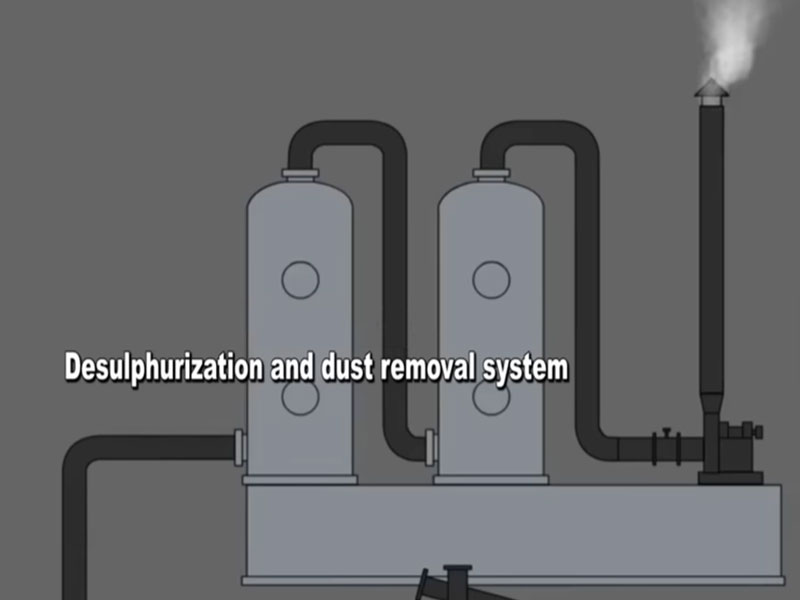

Environmental protection is also a significant concern, requiring significant investment in environmental protection facilities. It can effectively capture and treat the exhaust gas generated during the plastic pyrolysis process.

Plastic Waste to Energy Pyrolysis Plant Manufacturer

Mingjie Group designs and manufactures skid-mounted pyrolysis equipment, batch pyrolysis plant, and continuous pyrolysis plant for plastic waste to energy pyrolysis projects. These pyrolysis plants have been proven in numerous waste plastic pyrolysis projects in the Philippines, the Czech Republic, Thailand, South Korea, and China.

The waste plastic pyrolysis plant is an innovative plastic waste treatment equipment. It has the advantages of wide adaptability to raw materials, good environmental friendliness, high resource utilization efficiency and significant economic benefits.

Advantages of Waste Plastic Pyrolysis Technology

First, it is adaptable to a wide range of raw materials. Pyrolysis technology can effectively process both single-type waste plastics, such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), and mixed waste plastics with complex compositions.

Second, plastic waste to energy pyrolysis technology is environmentally friendly. Compared with traditional incineration, pyrolysis operates in an oxygen-free or oxygen-deficient environment, avoiding the production of harmful substances such as dioxins. This significantly reduces the risk of atmospheric pollution. We provide advanced exhaust gas purification systems to meet national exhaust emission standards.

Furthermore, the pyrolysis gas produced during the pyrolysis process can be partially reused in heating and other process steps, reducing reliance on external energy sources and lowering carbon emissions. Pyrolysis technology for waste plastics offers high resource utilization efficiency.

The pyrolysis oil produced during the pyrolysis process is a potentially valuable raw material with properties similar to crude oil. After processing in pyrolysis oil distillation plant, it can be converted into high-quality chemical products, such as diesel and gasoline. This ultimately transforms waste plastics into a new energy source.

Finally, plastic waste to energy pyrolysis technology offers excellent economic benefits. As the pyrolysis technology continues to mature and is applied on a large scale, its investment and operating costs gradually decrease.