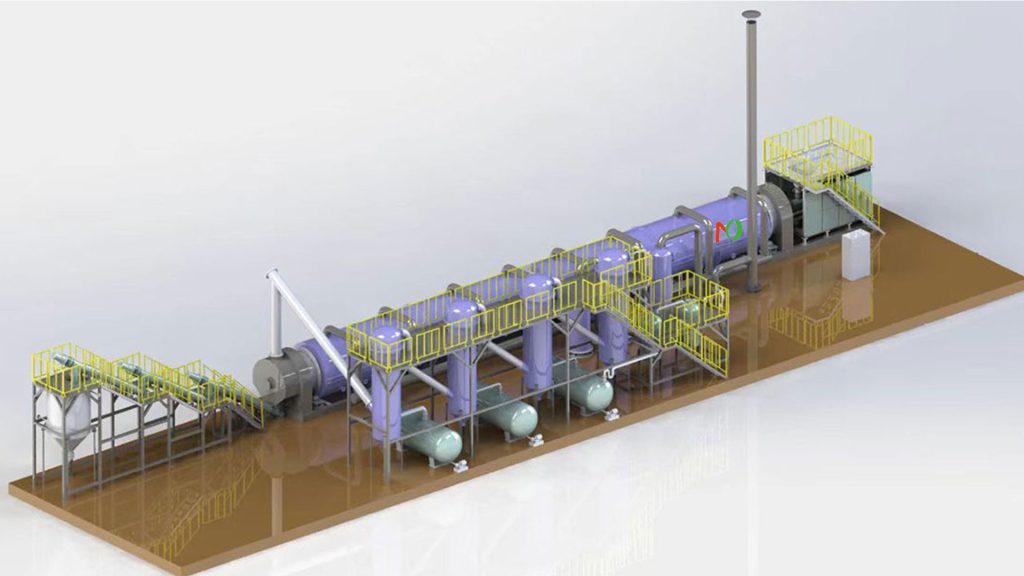

Waste plastic pyrolysis plant is an economical and efficient waste plastic treatment equipment that can convert waste plastics into fuel oil, combustible gas, and carbon black. However, the production of wax is a challenging problem during the pyrolysis process of plastic waste.

At lower pyrolysis temperatures, the degree of plastic molecular chain breakage is relatively small. This easily leads to the formation of large hydrocarbon molecules, which solidify into a waxy substance upon cooling. Its properties are similar to common paraffin wax. At room temperature, it is usually solid or semi-solid, with a high melting point and viscosity.

The production of wax causes numerous problems in the pyrolysis process of plastic waste. Wax easily adheres to and accumulates in parts of the plastic pyrolysis machine, such as pipes and condensers, gradually forming a thick layer of wax. This, in turn, reduces the inner diameter of the pipes or even completely blocks them. Ultimately, the pyrolysis products cannot be discharged smoothly, seriously affecting the continuity and stability of plastic to fuel oil production.

Therefore, effectively managing the wax produced during plastic pyrolysis is crucial for improving the efficiency of plastic pyrolysis recycling.

How to Handle the Wax Produced During the Pyrolysis Process of Plastic Waste?

Using Wax-Reducing Catalysts

For batch pyrolysis equipment, plastics and catalysts are thoroughly mixed in a specific ratio at the beginning of the production process to inhibit wax formation from the source. When the plastic raw materials are heated and decomposed in the pyrolysis furnace, the active components of the catalyst quickly interact with the plastic molecules. This changes the molecular cracking pathway, causing long-chain molecules to preferentially break down into smaller gaseous or liquid products.

Continuous pyrolysis equipment usually has a catalytic tower at the end of the production line. As the oil and gas produced by pyrolysis pass through the catalytic tower, they come into full contact with the catalyst, undergoing a catalytic reaction. At this point, the catalytic tower selectively converts the wax precursors in the oil and gas. This effectively decomposes or converts the waxy substances into other more easily handled substances before they enter subsequent pipelines and condensers. This achieves synchronous coordination of catalytic and pyrolysis reactions, minimizing the amount of wax generated throughout the entire pyrolysis system.

Temperature Control

The temperature at which wax solidifies is below 18℃. To prevent wax formation, the temperature of the plastic oil needs to be maintained above 18℃.

Insulation measures should be added to the outside of the buffer tank, such as installing heating belts and covering it with thermal insulation rock wool. This prevents the oil and gas from cooling and condensing in the buffer tank, thus preventing wax formation that could block pipes and equipment.

Configuring the De-waxing Tank

The de-waxing tank is a key piece of equipment for solving wax-related problems in pyrolysis process of plastic waste, and is usually installed between the buffer tank and the damping tank.

After the oil and gas produced by pyrolysis are discharged from the pyrolysis reactor, they first enter the buffer tank, where preliminary gas-liquid separation and pressure buffering take place. Subsequently, the oil and gas enter the de-waxing tank. The de-waxing tank uses a cooling medium to lower the temperature of the oil and gas inside the tank. When the temperature drops below the wax’s freezing point, the wax will condense and precipitate from the oil and gas, adhering to the tank wall.

By adding multiple de-waxing tanks, a large amount of wax is intercepted before entering subsequent pipelines and equipment. This effectively prevents wax accumulation in pipelines and condensers, ensuring the continuous and stable operation of the pyrolysis production line. This method of intercepting wax in advance not only reduces the risk of pipeline blockage but also lowers the cost of subsequent equipment cleaning and maintenance.

Regular Maintenance and Cleaning

Regular maintenance and cleaning are crucial measures to ensure the proper functioning of plastic pyrolysis equipment and reduce the impact of wax buildup.

For pipes prone to wax accumulation, mechanical cleaning tools can be used to scrape off the wax adhering to the inner walls of the pipes.

Chemical cleaning agents can also be adopted. Through circulating flushing, the wax reacts chemically with the cleaning agent, dissolving and removing it.

High-pressure water cleaning is another effective cleaning method. The powerful water jet produced by a high-pressure water gun is used to wash away the wax from the surfaces of pipes and equipment.