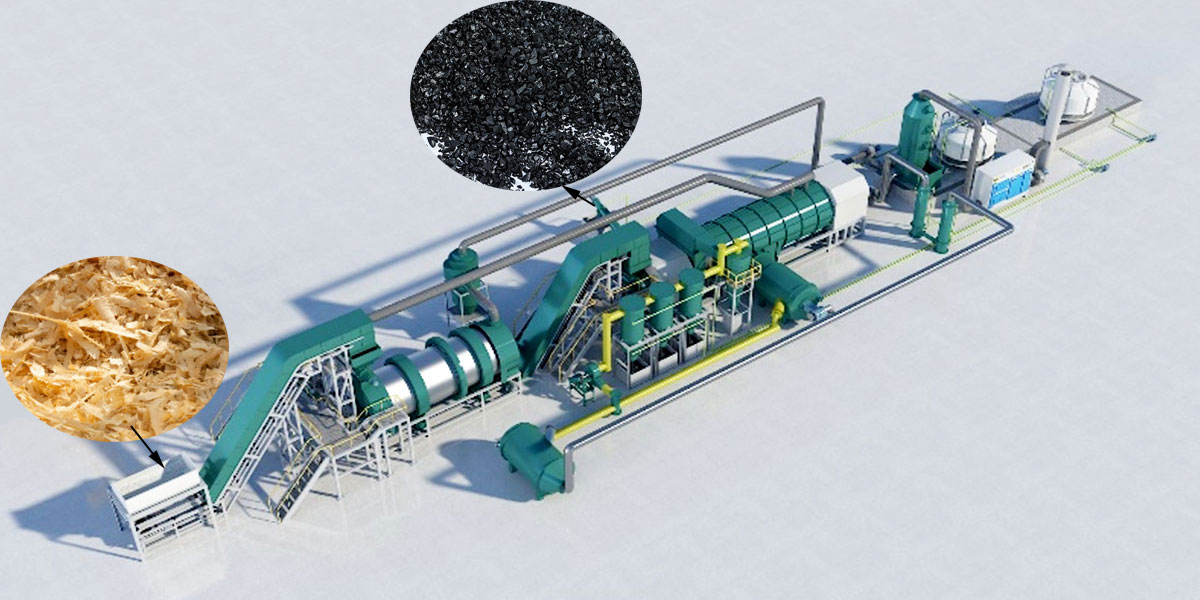

Choosing the right bamboo biochar production equipment is crucial for reducing costs and improving efficiency. Pyrolysis is the most common method for producing bamboo biochar. Biomass pyrolysis plant heats bamboo in the absence of oxygen, breaking it down to form biochar, bio-oil, and syngas.

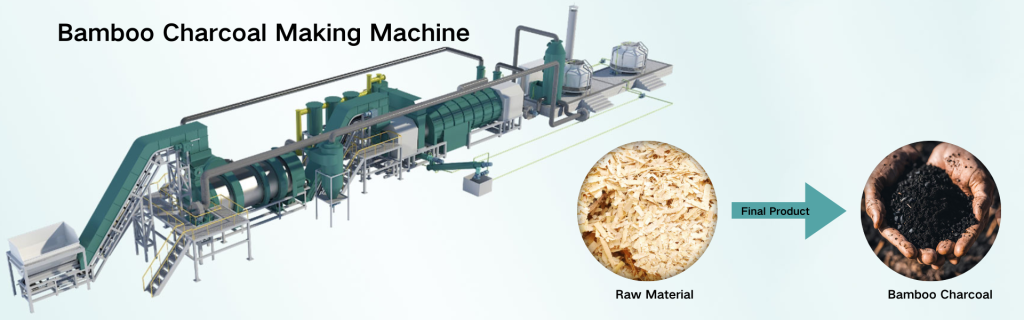

Mingjie Group provides continuous pyrolysis equipment for bamboo charcoal production, which efficiently processes waste bamboo chips. Continuous biomass carbonization plant utilizes continuous feeding and discharging systems, and automated systems significantly improve production efficiency and reduce labor costs.

We offer a variety of biomass pyrolysis equipment models to meet the needs of various biochar production scales, including the MJT-100, MJT-500, MJT-1000, MJT-2000, MJT-3000, and MJT-5000.

Choosing reliable and durable bamboo biochar production equipment is crucial. High-quality bamboo charcoal production equipment ensures long-term stable operation, reducing the need for frequent repairs and replacements, thereby reducing additional costs.

Furthermore, durable bamboo biochar production equipment can process large quantities of bamboo. Continuous carbonization equipment can operate 24 hours a day. It can increase production capacity and effectively reduce unit production costs.

Benefits of Bamboo Biochar Production

Covering waste bamboo biomass to biochar offers multiple benefits. It not only directly creates economic value, but also contributes to environmental protection and social development.

Economic Benefits

- Bamboo biochar can be sold directly as fuel, soil conditioner, or purification material.

- Certified biochar can earn Carbon Removal Certificates (CORCs) and participate in carbon market transactions.

- Byproducts such as wood vinegar and tar can be collected during the bamboo pyrolysis process, providing additional revenue streams.

Environmental Benefits

Bamboo biochar making machine can transform bamboo waste materials (bamboo shavings and sawdust) into valuable products, thereby aiding waste management. This reduces the amount of waste sent to landfills and incinerators and helps conserve natural resources.

The carbon sequestration potential of bamboo biochar makes it an important tool in combating global warming. By storing carbon in the soil, bamboo biochar can reduce atmospheric carbon dioxide levels, thereby contributing to climate change mitigation.

Bamboo biochar typically has a high carbon content, often exceeding 70%. This high carbon content makes it an effective carbon sequestering agent because it can store carbon in the soil for a long time.

Bamboo biochar production offers a sustainable and versatile solution for a variety of applications, from soil improvement and water treatment to energy production and waste management.

How Bamboo Biochar Achieves Continuous Production

Mingjie continuous carbonization equipment enables continuous and efficient production of bamboo biochar. Its greatest strength is its ability to operate 24/7, providing continuous support for biochar production. This significantly improves bamboo biochar production efficiency and meets the needs of large-scale production.

The pyrolysis process employed in continuous biomass carbonization equipment is the key to efficient bamboo biochar production. The entire bamboo pyrolysis and biochar production process is closely linked.

First, there is the continuous feeding stage. Fine bamboo raw materials are fed uniformly and continuously into the carbonization reactor through the feeding system.

Next, the process enters the drying and dehydration stage. A heat exchanger utilizes the waste heat generated during the carbonization process to dry the bamboo and remove moisture. This not only creates favorable conditions for subsequent pyrolysis and carbonization, but also achieves efficient energy utilization.

In the subsequent pyrolysis and carbonization stage, the bamboo undergoes complex thermochemical reactions in an oxygen-deficient, high-temperature environment. Organic matter gradually decomposes and transforms into biochar, producing byproducts such as combustible gases and tar.

After purification, a portion of these combustible gases and tar is recovered as fuel, providing continuous heat to the carbonization furnace, further improving energy efficiency. The remaining portion can be used as a chemical raw material for further processing.

Finally, the charcoal is discharged through water cooling. The biochar produced after pyrolysis carbonization is at a high temperature and is rapidly cooled by a water-cooling system. This ensures stable quality and performance of the bamboo biochar while preventing problems such as re-ignition caused by excessive temperatures.

The flue gas purification system also plays a vital role throughout the entire bamboo pyrolysis process. It effectively removes harmful gases and smoke generated during production, ensuring that emissions meet environmental standards and achieving green production.

The continuous carbonization plant, with its high efficiency and energy-saving features, has become the preferred equipment for large-scale bamboo biochar production. It provides strong technical support for the development of the bamboo biochar industry.