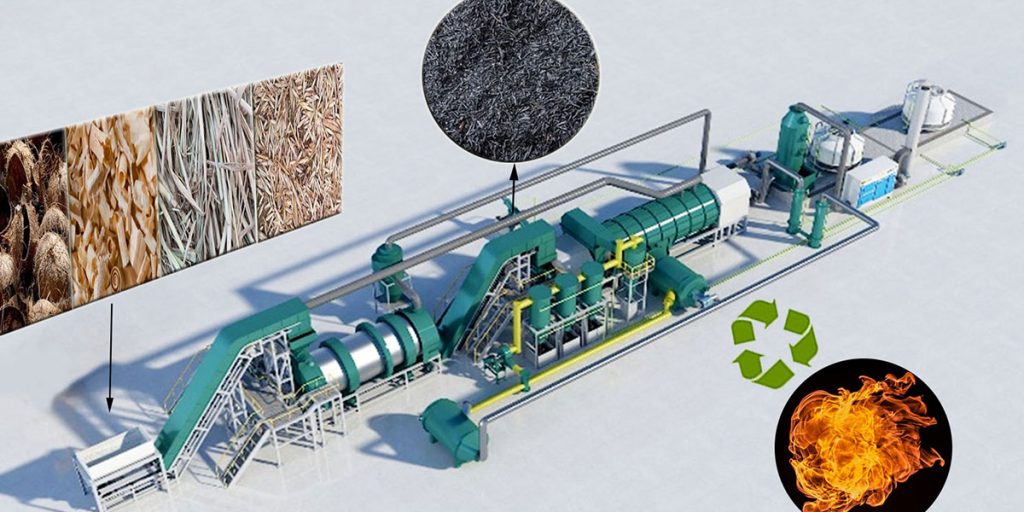

Biomass carbonization furnaces commonly suffer from low biochar production efficiency and poor environmental performance. This has hindered the development of the biochar industry. To address these issues, Mingjie Group has designed a continuous carbonization plant.

The continuous carbonization plant is mainly composed of feeding system, drying system, carbonization reactor, cooling tower, flue gas purifier, tail gas treatment device, PLC controller, fan and other equipment. Continuous carbonization equipment features high efficiency, energy conservation, environmental friendliness, and a high degree of automation.

Continuous Carbonization Plant Structure

The carbonization reactor features a double-layer insulation structure, which not only insulates heat but also prevents burns caused by excessively high outer temperatures.

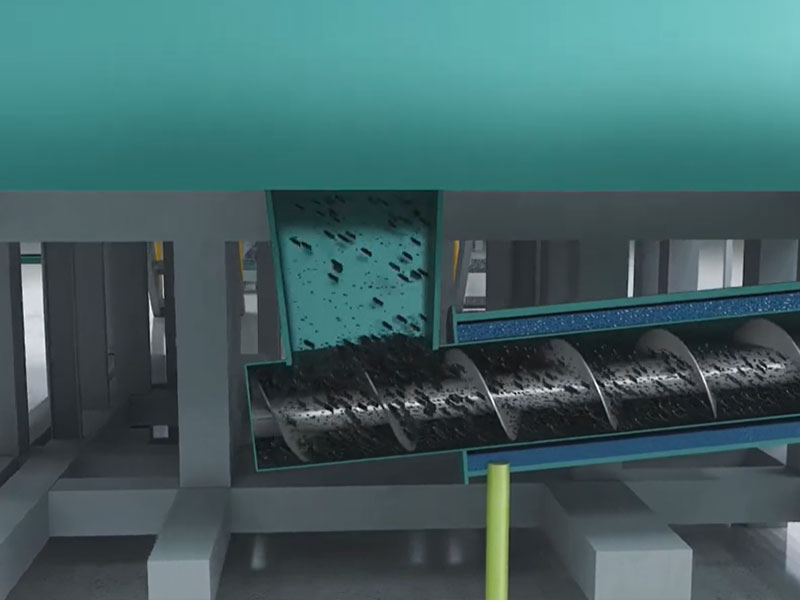

The carbonization reactor adopts a rotary kiln design, consisting of a slightly tilted, rotating cylinder. The material is lifted and tumbled by the inner wall of the cylinder, moving forward and fully exposed to the hot air flow. This ensures uniform heating of the biomass, and the residence time can be adjusted by adjusting the rotation speed and inclination angle, achieving continuous carbonization.

Biomass carbonization plant requires oxygen-deficient or oxygen-free conditions, so a screw is used as the discharge component. The carbonized granular carbonized product is conveyed via a spiral-shaped rotating blade, ensuring continuous and stable discharge.

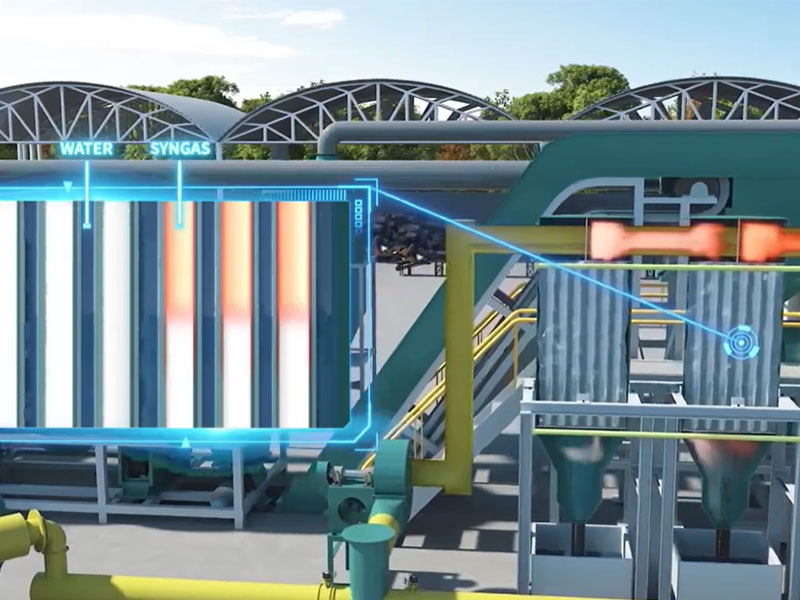

Both the carbonization reactor and the smoke oil condenser are equipped with temperature measuring devices.

The smoke oil condenser purifies the flue gas, tar, and other gases generated during the carbonization process. Water vapor is condensed into water through the furnace roof and then collected, providing environmentally friendly results.

Continuous biomass carbonization plant is an important environmentally friendly device used in biomass processing and biochar production. It converts biomass feedstock (such as wood, straw, rice husks, and fruit shells) into biochar, combustible gas, and tar. The biochar production process involves biomass pyrolysis, tail gas purification, and waste heat recovery.

Biomass Pyrolysis Process

Biomass pyrolysis is a thermochemical conversion process that converts biomass into high-value products through heating in an oxygen-deficient environment. The products of biomass pyrolysis are solid biochar (Biochar), liquid bio-oil (Bio-oil), and gaseous synthesis gas (Syngas).

The biomass pyrolysis process is not a single step, but rather proceeds through several stages: drying, pyrolysis, and carbonization.

During the drying stage, the biomass is heated, evaporating physically adsorbed water. This process consumes a significant amount of energy for feedstocks with high moisture content.

During the pyrolysis stage, the chemical bonds between cellulose and lignin undergo a dramatic breakage. This generates a large amount of volatile gases, steam, and tar precursors, while simultaneously forming a solid carbon structure.

During the carbonization stage, after the major volatiles are released, the fixed carbon content of the solid product is further increased.

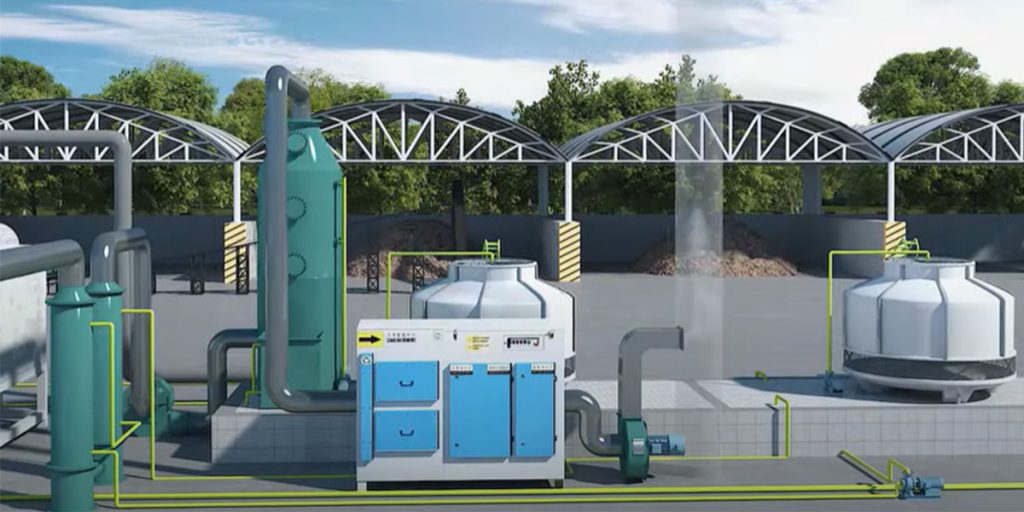

Tail Gas Treatment in Biochar Production

Tail gas treatment is a crucial step in the biochar production process. Its primary purpose is to reduce environmental pollution and recover valuable byproducts.

Biochar production is typically achieved through the pyrolysis of biomass under anoxic conditions. The biomass pyrolysis process produces several major off-gases.

- Volatile organic compounds (VOCs): such as tar and phenols.

- Carbon monoxide (CO) and carbon dioxide (CO₂): Products of incomplete and complete combustion.

- Methane (CH₄) and other light hydrocarbons: Products of biomass pyrolysis.

- Trace pollutants: such as sulfur compounds and nitrogen oxides.

Exhaust Gas Treatment Methods

Condensation: This method uses cooling equipment to lower the exhaust gas temperature, condensing high-boiling-point substances (such as tar) into liquids for separation. Its advantage is that it effectively removes most of the tar, facilitating subsequent treatment or resource recovery.

Scrubber: This method passes exhaust gas through a scrubber containing an absorbent (such as water, alkali solution, etc.) to absorb harmful gases (such as acidic gases SO₂ and NOx). Its advantage is that it effectively removes acidic gases and improves exhaust air quality.

Catalytic Oxidation: This method uses a catalyst to convert toxic and harmful gases into harmless substances (such as CO to CO₂). Commonly used catalysts include precious metals (such as platinum and palladium) or transition metal oxides. Its advantage is its high efficiency in converting harmful gases and is particularly suitable for treating low-concentration pollutants.

Combustion: Combustible gases (such as CO and CH₄) in the exhaust gas are directly introduced into a burner for complete combustion, producing CO₂ and H₂O. Its advantages are simplicity, directness, and the ability to effectively treat large amounts of combustible gases. However, careful control of combustion conditions is required to avoid secondary pollution.

Activated carbon adsorption: Utilizes the powerful adsorption capacity of activated carbon to capture volatile organic compounds (VOCs) in exhaust gases. This method is suitable for treating low-concentration, high-volume exhaust gases, but requires regular replacement or regeneration of the activated carbon.

Integrated treatment systems: Combine the advantages of multiple methods to design a complete exhaust gas treatment process. For example, condensation can be used to remove most tar, followed by a scrubber to remove acidic gases, and finally, catalytic oxidation or combustion can be used to further purify the exhaust gas.

For each specific biochar production process, an appropriate exhaust gas treatment solution should be selected. Factors such as the specific production process, exhaust gas composition and concentration, treatment costs, and environmental regulations must be considered. This approach not only effectively protects the environment but also maximizes resource utilization.