Pyrolysis technology, with its unique advantages, has become a more environmentally friendly and efficient method for oily sludge treatment. Oil sludge pyrolysis involves heating oil sludge at high temperatures in an oxygen-free environment, causing chemical reactions such as cracking and condensation.

Pyrolysis plant achieves the reduction, harmlessness, and resource recovery of oil sludge. This converts the organic matter within it into gaseous, liquid, and solid products.

The oil sludge pyrolysis process, carried out in a closed system, effectively controls the generation and emission of harmful substances such as dioxins. It also reduces the emission of pollutants such as waste gas and wastewater, minimizing its impact on the environment.

Pyrolysis equipment can effectively treat oily sludge. This not only solves the environmental pollution problems caused by oily sludge, but also converts it into a usable resource, which has important environmental and economic significance.

How to Achieve Optimal Pyrolysis of Oily Sludge Treatment?

Pretreatment

Pretreatment plays a crucial role in paving the way for the oily sludge treatment process. Screening and dehydration are two key steps in this oil sludge pyrolysis process.

Screening effectively removes large impurities, such as rocks and metal, from the sludge. These impurities can affect the proper functioning of the pyrolysis equipment during the pyrolysis process and may also cause wear and damage.

Dehydration is also crucial. Sludge typically contains a certain amount of water, and excessive water can have a number of adverse effects on pyrolysis.

During the initial heating phase of pyrolysis, a significant amount of heat is used to evaporate the water. This not only consumes significant energy, reducing energy efficiency, but also prolongs the oily sludge treatment process. Excessive water content can also make it difficult for the sludge to form a stable layer within the pyrolysis reactor. This affects uniform heat transfer and, consequently, hinders the pyrolysis reaction.

The sludge’s water content can be reduced to an appropriate range through mechanical dehydration combined with hot air drying.

Choosing Pyrolysis Equipment

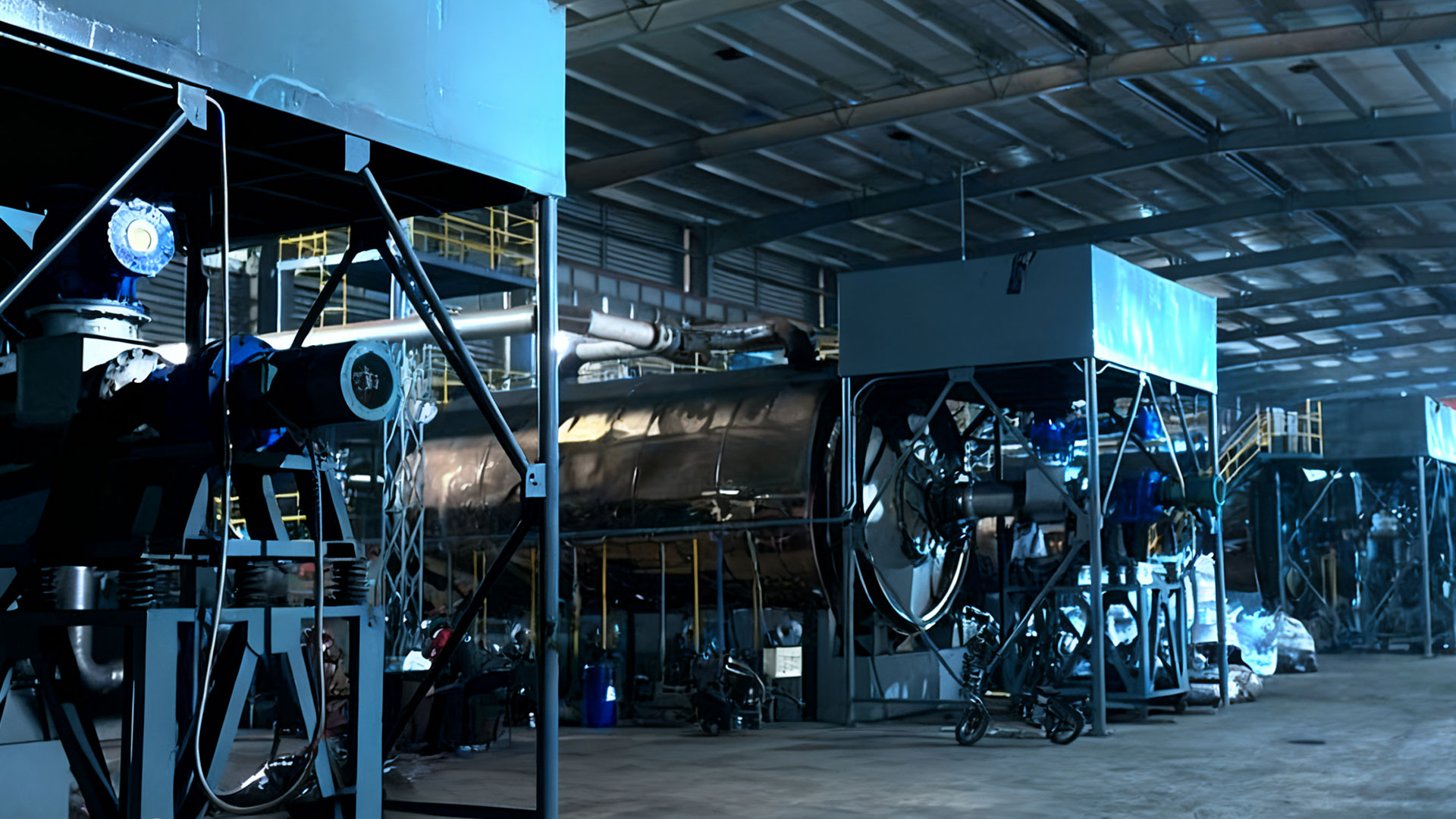

Rotary kilns are a common type of pyrolysis equipment used in oily sludge treatment, offering uniform heating and high pyrolysis efficiency. They are suitable for treating oil sludge of all sizes, from small-scale sludge treatment projects to large-scale industrial production.

Mingjie oily sludge pyrolysis equipment offers outstanding advantages, including high processing capacity, low energy consumption, and environmentally friendly performance. Their internal design incorporates a rational heat transfer structure, ensuring uniform heating of the material and improving pyrolysis efficiency.

The oil sludge treatment equipment is also equipped with a comprehensive oil and gas collection and purification system. This system utilizes highly efficient condensation, separation, and purification technologies. These systems effectively collect and purify the oil and gas generated by pyrolysis, ensuring product quality and safety.

A multi-stage condensation unit allows for the separate collection of oil and gas with different boiling points, improving oil purity and recovery rate. Advanced desulfurization, denitrification, and dust removal technologies purify pyrolysis exhaust gases to meet environmental standards and reduce environmental pollution.

Precise Control of Oil Sludge Pyrolysis Process

Temperature Control: Pyrolysis temperature is a key factor influencing oily sludge treatment results. It requires precise control based on the properties of pyrolysis objectives. The optimal pyrolysis temperature may vary for different sludge types.

- For sludges containing a higher proportion of light oil, the pyrolysis temperature can be appropriately lowered, generally around 350-450°C.

- For sludges containing a higher proportion of heavy oil, a higher pyrolysis temperature is required, typically between 450-550°C.

In practice, a staged heating method can be used. Preheating is performed at a lower temperature to fully volatilize the water and light components in the sludge. The temperature is then gradually increased to pyrolyze the heavy oil. Research has shown that a gradient heating method can better adapt to the pyrolysis requirements of different sludge components, improving oily sludge treatment efficiency and pyrolysis product quality.

Residence Time: The optimal residence time setting directly affects the pyrolysis treatment effect. Sludges with different components have optimal residence time windows.

- Light oil sludge, due to its relatively simple composition, undergoes rapid pyrolysis, with a residence time of approximately 60 minutes sufficient to fully decompose most organic matter.

- Heavy oil sludge, however, has a complex molecular structure and requires more time for pyrolysis, typically 90-120 minutes.

In actual oily sludge treatment, a variable-speed screw feeder can be used. It automatically adjusts the conveying speed based on the characteristics of the sludge, enabling precise control of residence time. This ensures optimal processing efficiency and pyrolysis product quality.