Practice has proven that slow pyrolysis is the optimal technology for producing rice husk biochar. Rice husk can be converted into high-value biochar through pyrolysis and carbonization. Rice husk biochar production equipment is the core of this conversion process.

For rice husks, their inherently high silicon content presents both a challenge and an opportunity. During the slow pyrolysis process, the silicon is retained and fixed within the biochar, making its structure more stable and its porosity more developed. However, this also places higher demands on the wear resistance of biomass pyrolysis equipment.

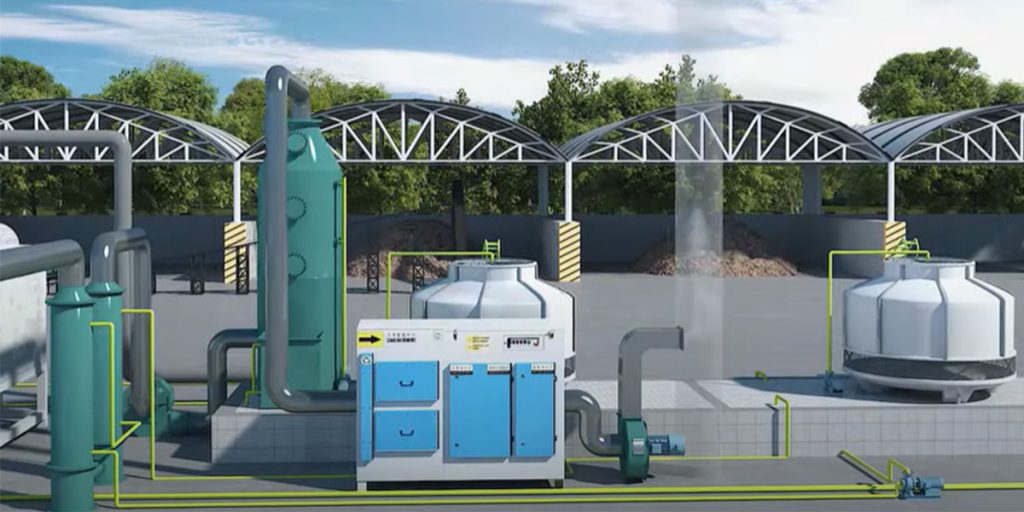

A complete rice husk biochar production equipment system integrates multiple functional units. Each unit plays a vital role in ensuring the smooth pyrolysis and carbonization process and the quality of the rice husk biochar.

Core Components of Rice Husk Biochar Production Equipment

Pretreatment System

The rice husk pretreatment system includes a dryer and conveyor. Rice husks typically contain a high moisture content, and the drying system reduces their moisture content to below 15% through drying. This significantly improves pyrolysis efficiency and reduces energy consumption. Furthermore, a stable conveying system ensures continuous feeding.

Rice Husk Feeding System

The feeding system is the starting point of the entire rice husk biochar production line. It is responsible for evenly and stably delivering the raw rice husks to the pyrolysis reactor. Key components of this system include the hopper, conveyor, and feed control valve.

The hopper is used to store a certain amount of rice husks, ensuring a continuous supply of raw material.

Common conveyors include screw conveyors and belt conveyors. Screw conveyors are suitable for short conveying distances and limited space, effectively preventing rice husk leakage and the intrusion of foreign matter. Belt conveyors are more suitable for long-distance conveying and high-capacity production lines. However, they require strict sealing measures to prevent dust contamination.

The feed control valve adjusts the feed rate based on the operating conditions of the pyrolysis reactor. It ensures that the amount of rice husk entering the reactor matches the pyrolysis capacity, thereby preventing incomplete reaction and material accumulation within the reactor.

Pyrolysis Reactor

The pyrolysis reactor is the core component of the rice husk process. Within the reactor, the rice husk undergoes a pyrolysis and carbonization process, ultimately producing biochar and syngas. The Mingjie pyrolysis machine utilizes a rotary kiln reactor, a rotating cylindrical structure. This continuously turns the material, ensuring uniform heating and a thorough reaction. The Mingjie biomass pyrolysis reactor is highly adaptable to rice husk particle size and moisture content, making it widely used in large-scale rice husk biochar production lines.

Heating System

The heating system provides the necessary heat for the pyrolysis reaction within the reactor. The initial heating method for the pyrolysis reactor can be electric heating, gas heating, or biomass fuel heating. Syngas is generated during the biochar production process. After purification, it can be used as a heating source for the reactor.

Gas Treatment System

The rice husk pyrolysis process produces a large amount of pyrolysis gas, which primarily contains combustible components such as methane, hydrogen, and carbon monoxide, as well as harmful substances such as tar and dust. Direct discharge of these gases into the atmosphere not only pollutes the environment but also wastes precious energy resources. Therefore, the gas treatment system is a crucial component of rice husk biochar production equipment.

Common dust collectors for pyrolysis gas treatment include cyclone dust collectors and bag filters. Cyclone dust collectors have a simple structure and low cost, but their dust removal efficiency for fine dust is relatively low. Bag filters have high dust removal efficiency and effectively remove fine dust, but they are prone to clogging and require regular cleaning and replacement of filter bags.

Tar removers are used to remove tar from pyrolysis gas. Mingjie Biomass Pyrolysis Plant uses the condensation method to separate synthesis gas and tar. It uses a condenser to cool the pyrolysis gas, condensing the tar into liquid and separating it.

The spray tower further purifies the syngas, removing impurities such as tar. The purified, high-quality syngas is then fed back into the reactor combustion chamber, providing over 95% of the heat required for the pyrolysis process. This is key to the economic viability of Mingjie continuous biomass pyrolysis equipment.

Biochar Collection System

After rice husks are pyrolyzed and carbonized in a reactor, the resulting biochar reaches a high temperature (typically above 500°C). If exposed directly to air, it can easily burn or oxidize, affecting the quality and yield of the biochar. Therefore, timely cooling and collection of the biochar is essential.

Mingjie rice husk biochar collection and cooling system primarily utilizes water-cooled coolers. Water-cooled coolers offer high cooling efficiency but consume a lot of water. The cooled biochar is collected in a collection device, which can be a silo or packaging machine.