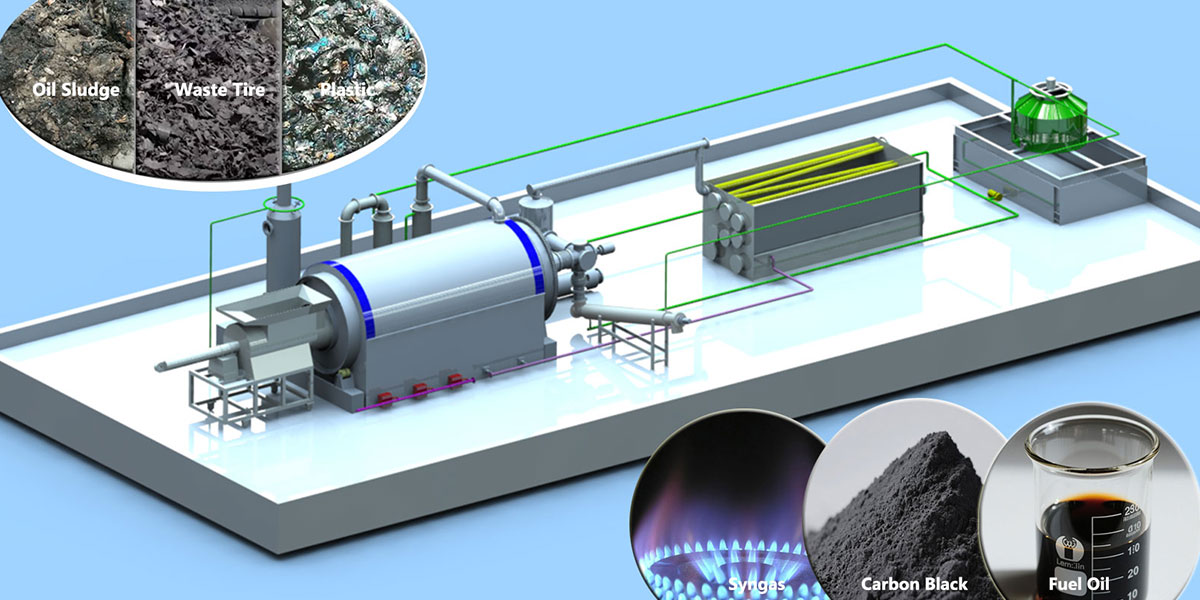

What is semi-continuous pyrolysis? Semi-continuous pyrolysis is mainly the process of feeding solid waste into the pyrolysis reactor in a semi-continuous manner. Through indirect heating, the organic components in the solid waste undergo thermal decomposition reactions at high temperatures to generate gas, liquid and solid products.

Compared with full continuous pyrolysis, semi continuous pyrolysis can flexibly adjust the feeding time and reaction conditions according to the properties and treatment requirements of the solid waste. Compared with batch pyrolysis, it can improve the efficiency of solid waste treatment to a certain extent and reduce the idle time of pyrolysis equipment.

How is semi continuous pyrolysis achieved? Semi continuous pyrolysis of solid waste is achieved through semi continuous pyrolysis plant. The semi continuous pyrolysis plant mainly includes feeding system, pyrolysis reactor, and product separation system.

What Equipment is Needed for Semi Continuous Pyrolysis?

Pyrolysis Reactor

The pyrolysis reactor is the core device of semi-continuous pyrolysis. Mingjie pyrolysis plant mainly adopts rotary kiln reactor. The rotary kiln reactor heats the material evenly through rotation, has strong adaptability, and can handle large-scale solid waste. As the power source of the semi continuous pyrolysis equipment, the motor provides power for the entire pyrolysis process.

The reactor provides a special place for solid waste pyrolysis reaction. The creation of its internal environment is crucial for the smooth progress of the pyrolysis reaction. During the pyrolysis process, the reactor needs to create a specific environment of high temperature and anaerobic.

High temperature conditions can provide sufficient energy for macromolecular substances to break their chemical bonds and cause decomposition reactions.

The anaerobic environment is to avoid the occurrence of oxidation reactions. It ensures that the pyrolysis reaction can proceed along the expected path and prevents the product from being oxidized. Thus, the purity and quality of the pyrolysis products are guaranteed.

Take the pyrolysis of waste tires as an example. In the reactor, when the temperature rises to 280-320℃ in a slightly positive pressure oxygen-free environment, the chemical bonds of the high molecular rubber hydrocarbons in the tires are broken, realizing the transformation of macromolecular substances into small molecular substances.

Draft Fan

The induced draft fan is responsible for exhausting the waste gas generated in the semi continuous pyrolysis equipment. The blower can effectively control the pressure inside the equipment by adjusting the air supply volume. A good balance needs to be maintained between the blower and the induced draft fan.

The induced draft fan is an important part of ensuring the smooth progress of the pyrolysis process. It ensures that the exhaust gas can be discharged in a timely and efficient manner, maintaining a good environment inside the pyrolysis equipment. During the pyrolysis reaction, a large amount of exhaust gas will be generated. These exhaust gases contain a variety of components, such as pyrolysis gas, water vapor, and some incompletely reacted substances. The induced draft fan uses its powerful exhaust capacity to extract these exhaust gases from the core pyrolysis areas such as the reactor, so that they can smoothly enter the subsequent processing links.

The induced draft fan plays a vital role in maintaining the pressure balance in the pyrolysis equipment system. During the semi continuous pyrolysis process, the pyrolysis reaction in the reactor will continuously produce gas, causing the internal pressure to increase. If these gases cannot be discharged in time, excessive pressure may threaten the safe operation of the equipment and even cause dangerous accidents. The induced draft fan can effectively reduce the pressure in the reactor by continuously extracting exhaust gas, keeping it within a stable and safe range.

Feeding System

The feeding system adopts semi continuous feeding method to ensure the controllability and stability of the feeding process. It is mainly composed of storage bin, feeder and conveying device. The storage bin is used to temporarily store solid waste. The feeder can be based on the set time interval and feed amount. The conveyor belt transports the solid waste evenly and stably to the pyrolysis reactor.

Pyrolysis Products Separation System

The pyrolysis products of gas, liquid and solid need to be separated. The gas product is removed from impurities by condensation, adsorption. The liquid product is refined by static stratification, distillation system. The solid product is processed by screening, magnetic separation to achieve effective separation of different products.

The manifold plays a key role in connecting and distributing pyrolysis products in semi continuous pyrolysis equipment. It guides the pyrolysis products from the reactor to the corresponding processing equipment or storage container to ensure that the pyrolysis products can be reasonably processed and utilized.

During the semi continuous pyrolysis process, the manifold transports the pyrolysis gas to the subsequent purification and utilization device. It guides the pyrolysis oil to the residual oil tank for storage. The residue is transported to the slag discharge system for processing.

Condenser

The condenser is a highly efficient condensing device that integrates multiple functions. It plays an important role in further condensing and separating pyrolysis products in the pyrolysis equipment. The three-in-one condenser usually integrates cooling, condensation and separation functions. It can deeply process the pyrolysis gas, fully condense the condensable gas into liquid, and effectively separate it from the non-condensable gas.

In the plastic pyrolysis project, the three-in-one condenser can condense most of the oil and gas in the pyrolysis gas into liquid fuel oil, which improves the recovery rate of fuel oil. At the same time, the non-condensable gas is separated and can be used as fuel gas for heating the pyrolysis equipment.

Slag Discharge System

The slag discharge system is a key component of the pyrolysis equipment responsible for handling the pyrolysis solid residue. Mingjie’s slag discharge system mainly uses a water-cooled spiral slag discharge, which can timely and effectively cool and discharge the carabon black. It pushes the residue along the spiral groove through the rotation of the spiral blade, thereby realizing the transportation and discharge of the residue. The slag discharge system plays a vital role in maintaining the normal operation of the pyrolysis equipment and ensuring the continuity of pyrolysis.

Pyrolysis Oil Tank

The pyrolysis oil tank is a container specially used to store the pyrolysis oil produced during the semi continuous pyrolysis process. Pyrolysis oil is an important component from solid waste pyrolysis. It has certain economic value, and can be used as fuel oil or chemical raw material.

Flue Condenser

The flue condenser is mainly used to recover the heat in the pyrolysis gas, and further cool and purify the pyrolysis gas. It uses the heat exchange principle to transfer the heat in the pyrolysis gas to the cooling medium to reduce the temperature of the pyrolysis gas. The water vapor and part of the condensable gas condense into liquid, thus achieving the dual purpose of heat recovery and gas purification.

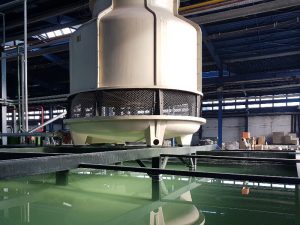

Cooling Tower

The cooling tower is mainly responsible for cooling the circulating water in the pyrolysis equipment to ensure the stable operation of the entire system. During the semi continuous pyrolysis process, many equipment needs to be cooled by circulating water to maintain its normal operating temperature. The cooling tower uses the principle of latent heat of evaporation of water to transfer the heat of the circulating water to the air. The circulating water temperature is reduced, thereby cooling the equipment.

Exhaust Combustion Chamber

The exhaust combustion chamber is used to treat the incompletely burned gas generated during the semi continuous pyrolysis process to reduce environmental pollution. In the pyrolysis reaction, some incompletely burned gas containing harmful substances may be generated. If it is directly discharged into the atmosphere, it will cause serious pollution to the environment. The exhaust combustion chamber provides a high temperature and sufficient oxygen environment to allow these incompletely burned gases to undergo secondary combustion. The harmful substances in them are converted into harmless substances, such as carbon dioxide and water. The purified gas is then discharged into the atmosphere.

In the municipal solid waste pyrolysis project, the exhaust combustion chamber performs secondary combustion treatment on the waste gas containing carbon monoxide generated by incineration. It effectively reduces the content of pollutants in the waste gas and reduces the harm to the environment.

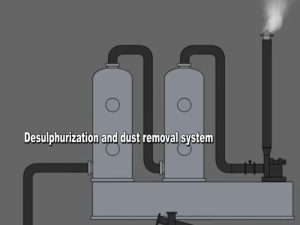

Spray Tower

The spray tower plays an important role in purifying pyrolysis gas and removing harmful substances in semi continuous pyrolysis plant. Its working principle is to use the spraying effect of liquid to wash and absorb pollutants in pyrolysis gas.

In the spray tower, liquid enters from the top of the tower and is sprayed into mist or raindrops through the nozzle. Pyrolysis gas enters from the bottom of the tower and is in close contact with the mist or raindrop liquid for mass transfer, so that the soluble components in the gas are absorbed. Thus, the purification of pyrolysis gas is achieved.

For example, when treating pyrolysis gas containing acidic gas, alkaline solution can be used as spray liquid. Through acid-base neutralization reaction, acidic pollutants in pyrolysis gas can be effectively removed.