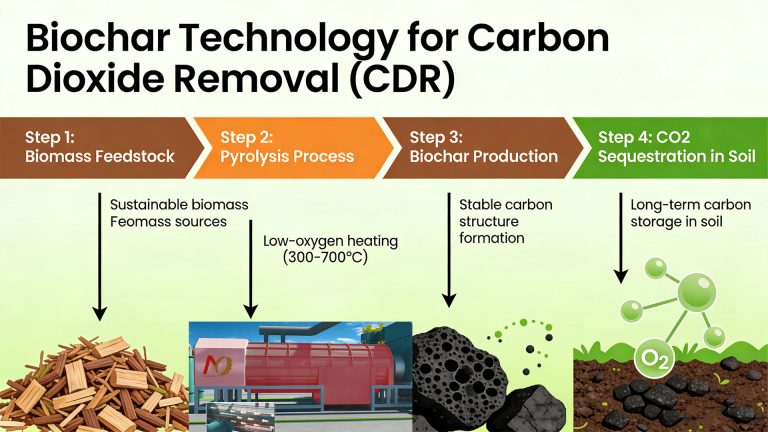

Small charcoal making machine has low cost, suitable for customers with limited budgets. It adopts continuous pyrolysis technology, providing an efficient and environmentally friendly solution for the production of small-scale biomass to biochar. Biomass pyrolysis technology can convert waste biomass into products such as biochar, syngas and tar.

The main equipment of a small biochar production line is a crusher, dryer, and biomass pyrolysis machine. The raw materials for small charcoal making machine can be found everywhere in the countryside, such as straw, rice husks, corn cobs, sawdust, miscellaneous wood, branches, peanut shells, nut shells, etc. Generally, about 2.5 tons of raw materials can be processed into 1 ton of charcoal.

Small-scale biomass pyrolysis machines have a very broad application prospect in the energy field, providing a new way to solve energy shortages and environmental problems. However, an unavoidable question is facing many investors and users: what is the cost of small charcoal making machine? This is not only related to the investment decisions of enterprises and individuals, but also affects the popularization and promotion of this technology.

Small Charcoal Making Machine Cost

The small charcoal making machine cost is an important expense that investors need to consider first. The biomass to biochar production equipment price varies due to many factors, covering models, specifications, technical parameters and brands. The price range of small biomass pyrolysis machines on the market is relatively wide, ranging from tens of thousands of dollars to hundreds of thousands of dollars.

Taking a small-scale biomass pyrolysis machine for laboratory use with a small processing capacity and a relatively simple structure as an example, its price is usually around 60,000 to 70,000 US dollars. This type of small charcoal making machine is mainly used for experimental research and small-batch production in scientific research institutions or small enterprises. And the processing capacity is only a few kilograms to more than ten kilograms each time. It can accurately control the temperature and meet the strict requirements of the experiment for temperature accuracy.

The biomass carbonization machine with a slightly larger processing capacity is suitable for small-scale production, such as biochar equipment with a daily processing capacity of 1-2 tons. The price of small-scale biomass pyrolysis equipment is about 200,000 to 300,000 US dollars. This type of biochar production equipment is more complex in structure and is equipped with a variety of components, such as a spiral feeder, a fan, and a combustion system to achieve continuous production and improve production efficiency.

Factors Affecting the Biochar Production Equipment Cost

The technical level and equipment quality of small charcoal making machine have a profound impact on costs. This impact is not only reflected in the purchase cost of the equipment, but also gradually manifested in the long-term use process.

Pyrolysis Technology

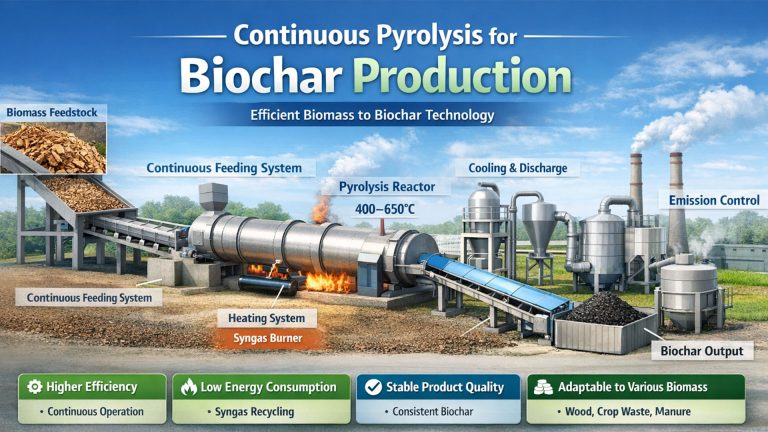

From a technical perspective, advanced pyrolysis carbonization technology can significantly improve energy utilization efficiency and reduce operating energy consumption costs. The continuous pyrolysis process enables biomass to absorb heat more fully during the pyrolysis process, improve the rate and conversion rate of the pyrolysis reaction, and thus reduce energy waste.

At the same time, advanced temperature control systems can accurately control the temperature of the pyrolysis reaction to avoid increased energy consumption due to excessive temperature fluctuations.

In this way, although the purchase cost of a small charcoal making machine may be relatively high. But in the long run, the energy cost saved will be a considerable amount, effectively reducing the total cost.

Equipment Quality

In terms of equipment quality, high-quality small charcoal making machines have higher stability and reliability, which can reduce equipment failures and maintenance times, and reduce maintenance costs. Mingjie biomass carbonization equipment uses high-strength steel and advanced manufacturing technology, and key components such as reactors and heating systems have undergone strict quality inspections and optimized designs.

This enables biochar production equipment to maintain good performance during long-term operation, greatly reducing economic losses caused by equipment downtime and maintenance. They tend to have a longer service life. This also reduces the depreciation cost of the small charcoal making machine to a certain extent.

Large Continuous Biomass Carbonization Plant Price

As for large-scale continuous biochar production line, the biomass carbonization plant price may be as high as millions of US dollars. These large-scale biochar production equipment usually have a higher degree of automation and can achieve large-scale industrial production. It can process several tons or even tens of tons of biomass raw materials per day.

The processing capacity of the biomass pyrolysis plant is undoubtedly one of the key factors affecting the price. The larger the processing capacity of the biochar production equipment, the more complex its internal structure and production process are. It needs to be equipped with high-power motors, durable materials and more sophisticated control systems to ensure the stability of the biochar pyrolysis machine. This increases the cost of the biochar production line, which in turn leads to price increases.

The technical level of the biomass carbonization machine is also an important factor in determining the price. Such as efficient continuous pyrolysis process, precise temperature control system, waste heat recovery technology, flue gas purification system and automatic control system. These systems can improve pyrolysis efficiency, reduce energy consumption, reduce manual intervention, and thus improve product quality and production efficiency.