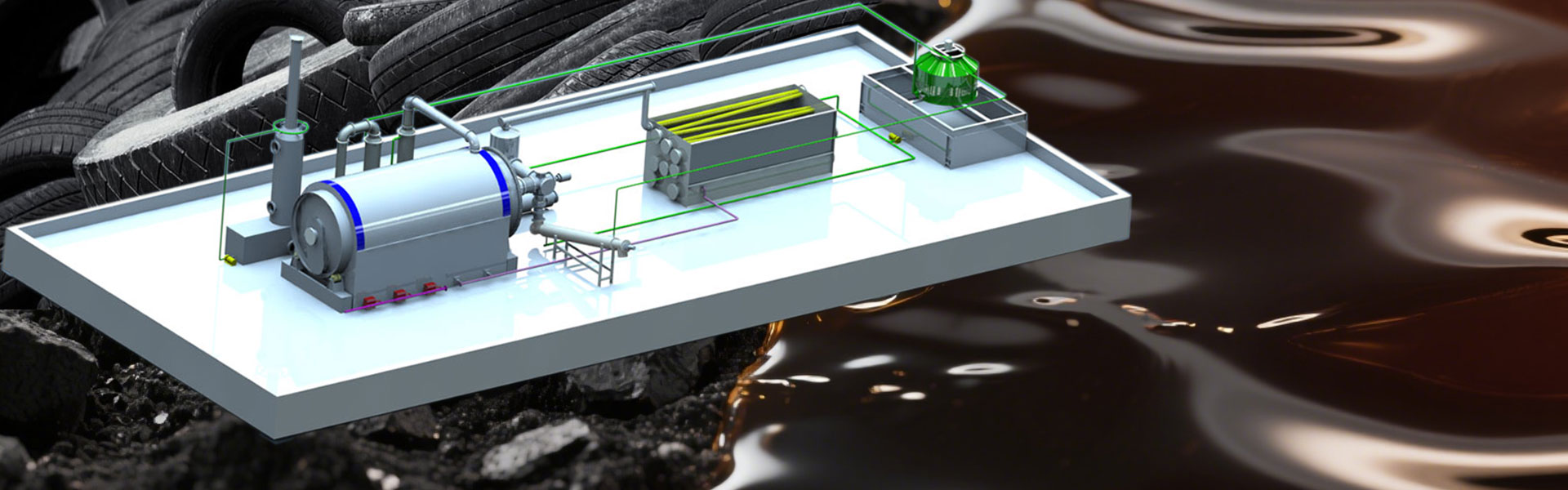

Tire To Oil Pyrolysis Plant transforms waste tires into tire pyrolysis oil (TPO) through pyrolysis process. In the pyrolysis plant, waste tires become raw materials for fuel oil, carbon black, steel wire and combustible gas resources with important economic value.

Batch Tyre To Oil Pyrolysis Plant

The production process of batch pyrolysis plant is intermittent. Its advantages are low investment in pyrolysis equipment and relatively simple operation, which is suitable for small-scale production or situations with high production flexibility requirements.

Some small and medium-sized tire to oil pyrolysis projects will adopt batch pyrolysis plants. It can process the entire tire without crushing.

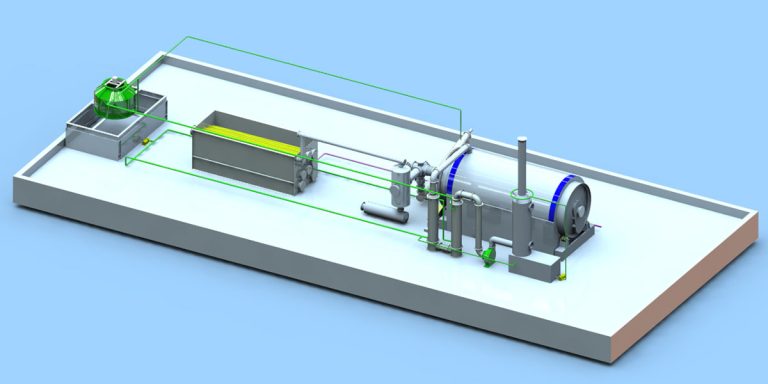

Continuous Tire To Oil Pyrolysis Plant

The continuous pyrolysis plant has a high degree of continuity in the production process, which can achieve large-scale and stable production. The fully automatic tire pyrolysis plant can improve production efficiency and reduce the cost per unit product. At the same time, it is also conducive to precise control of the production process and ensure the stability of product quality.

Some large tire pyrolysis projects will use continuous tire to oil pyrolysis plants. It continuously feeds the crushed tire rubber powder into the pyrolysis reactor for pyrolysis reaction to produce pyrolysis oil, carbon black and synthesis gas products.

If you’re interested in purchasing or learning more about Tire to Oil Pyrolysis Plant, you can contact Mingjie Pyrolysis Plant Manufacturer. Let me know if you need help finding specific models!

Tyre Pyrolysis Products

Pyrolysis of waste tyre refers to converting waste tire into pyrolysis oil (40%-45%), carbon black (30%-35%), steel wire (15%) and syngas (10%) under oxygen-free or oxygen-deficient and high temperature conditions.

Tyre Pyrolysis Oil

Tire pyrolysis oil is a liquid fuel oil formed by the oil and gas produced by the pyrolysis reactor through the condensation system. Tire pyrolysis oil has a high calorific value and can be directly burned as fuel for industrial boilers. It can also be converted into diesel through distillation equipment.

Tire pyrolysis oil is usually a dark, turbid, dense liquid with a strong odor. The components are mainly composed of monocyclic aromatic hydrocarbons and heavier hydrocarbon compounds, and also contain a small amount of impurities such as sulfur and nitrogen.

The calorific value of tire pyrolysis oil is generally greater than 40MJ/kg, and the density is 0.950-0.980g/ml. The flash point is lower than 25℃, and the pH value is about 7.6.

Carbon Black

Pyrolytic carbon black is the solid residue collected by the slag discharge system in the tire to oil pyrolysis plant.

In addition to carbon, tire pyrolysis carbon black also contains a certain amount of ash, a small amount of steel wire, heavy metals and other impurities. It has a large specific surface area and a certain adsorption capacity. Compared with commercial carbon black, the surface of tire pyrolysis carbon black contains a variety of carbon black mixtures, and its surface activity is relatively poor.

The non-condensable synthesis gas is collected into a storage tank through a gas recovery device and can be supplied to the burner of the heating system as fuel. The flue gas generated by the burner in the heating system is processed by a dust removal and purification system to ultimately meet the environmental protection requirements of gas emissions.

Tire To Oil Pyrolysis Plant Case

Because the Tire To Oil Pyrolysis project has high profits and fast return on investment, more and more people are investing in tire pyrolysis projects. Tire To Oil Pyrolysis Plant is equipped with some pollution prevention and control measures and safety devices, achieving environmental protection standards, energy saving and emission reduction, and safety and harmlessness. For example: water-cooled carbon black slag removal system, flue gas purification system, buffer tank, oil and gas separator and safety valve, etc.