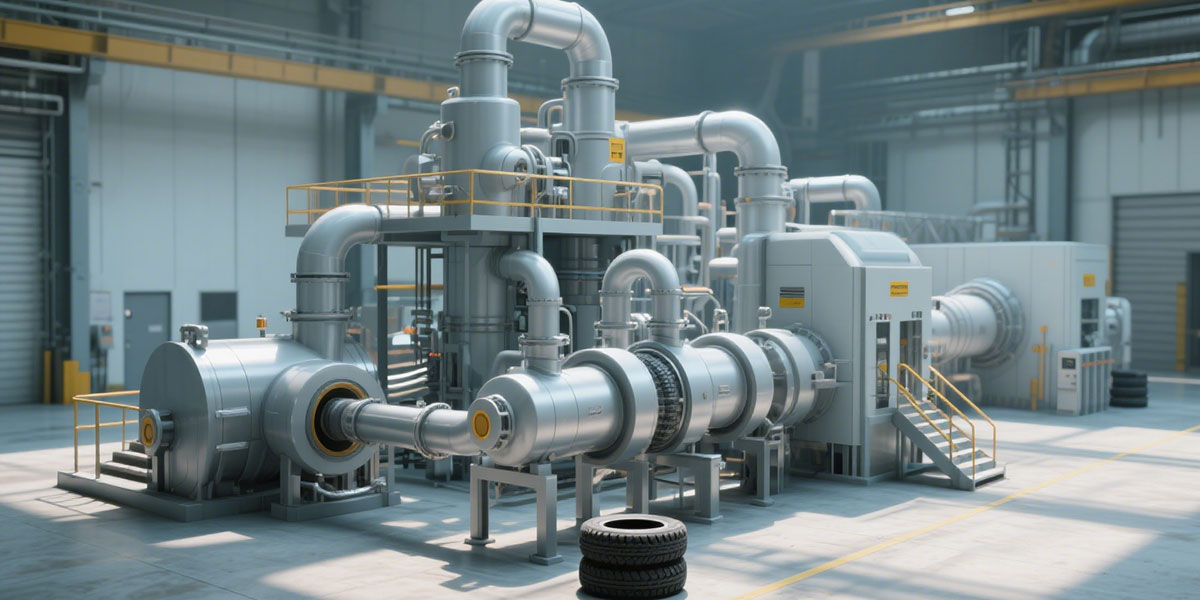

How Does Scrap Tyre Recycling Plant Process Waste Tire?

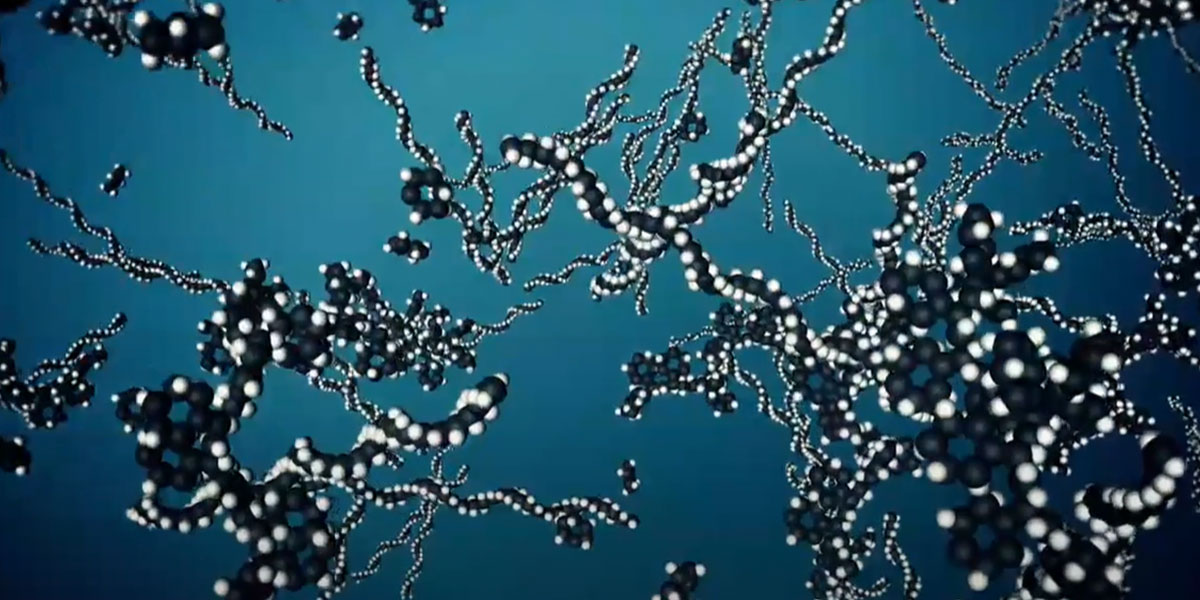

The scrap tyre recycling plant utilizes mechanical recycling and pyrolysis technology to achieve resource utilization, ensuring an environmentally friendly and efficient process. The following are the main processing steps and methods: Pretreatment Stage Sorting When tires arrive at a scrap tyre recycling plant, they go through pre-processing. This stage begins by sorting them based on … Read more