Both tyre pyrolysis and plastic pyrolysis convert waste into pyrolysis oil, carbon black and syngas through pyrolysis plants. But the composition of their pyrolysis products is different. Tyre pyrolysis oil is extracted from waste tires containing rubber, carbon black and other additives. Plastic pyrolysis oil is extracted from various plastic wastes such as polyethylene, polypropylene and polystyrene.

The difference in pyrolysis raw materials leads to differences in the physical and chemical properties (calorific value, viscosity and composition) of pyrolysis oil. These differences ultimately affect the different applications of pyrolysis oil.

Different Raw Materials in Plastic and Tyre pyrolysis

Plastics Pyrolysis: Plastics suitable for pyrolysis include polyethylene (PE), polypropylene (PP), polystyrene (PS), and ABS. Plastics come in a variety of forms, including films, pipes, plates, and injection molded parts. They are relatively soft and generally do not contain metal components. The pretreatment of waste plastics is relatively simple, usually requiring only preliminary treatment such as cleaning and crushing.

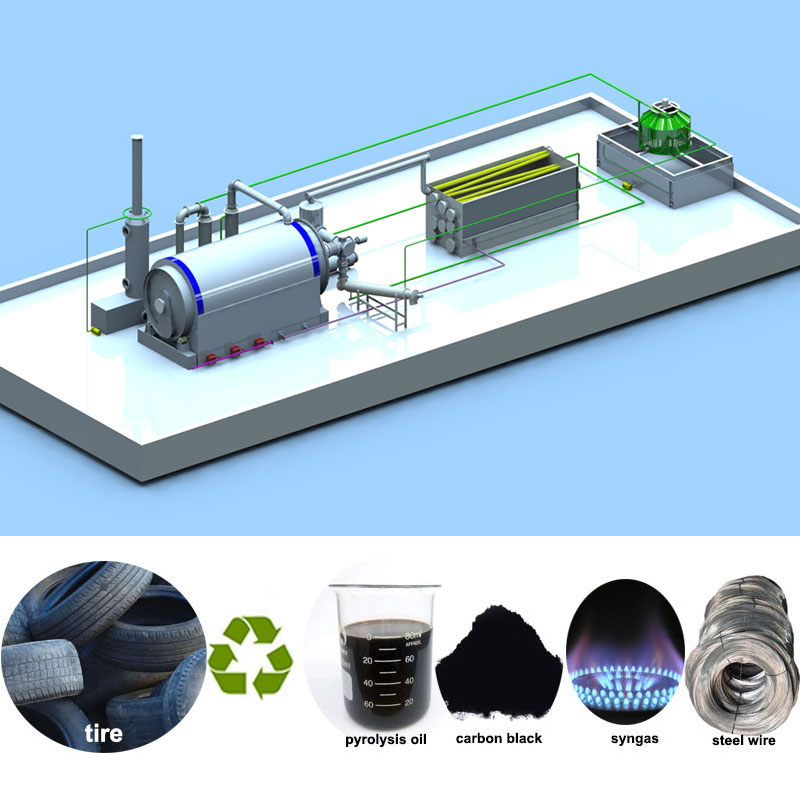

Tyres Pyrolysis: Tyres are mainly composed of natural rubber, synthetic rubber, carbon black, steel wire, and a variety of additives. They have a complex structure, a tough texture, and contain metal components. This usually requires more complex pretreatment of tires before tire pyrolysis, such as cutting, crushing, and removing steel wires.

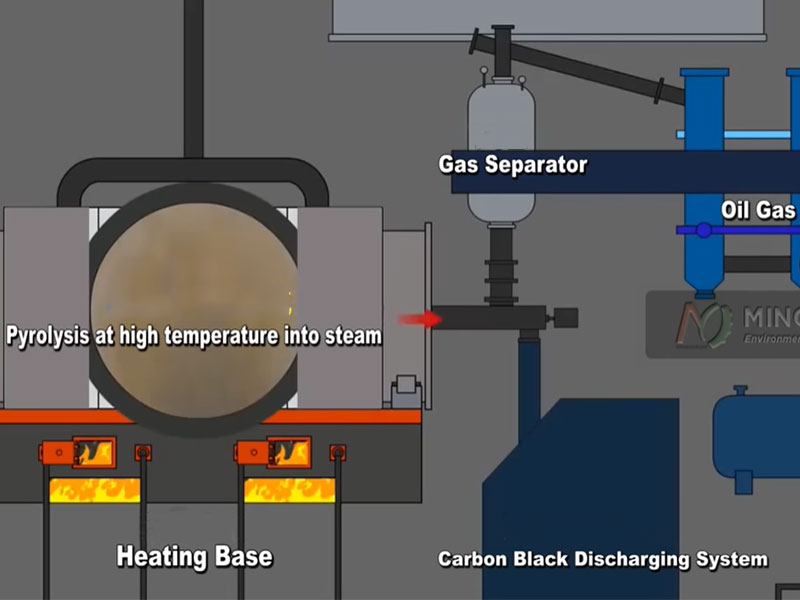

Different Pyrolysis Process

Plastic Waste Pyrolysis Process: The pyrolysis temperature of plastics is usually around 400-600 degrees Celsius, which varies depending on the type of plastic. In addition to traditional heating methods, new technologies such as microwave heating are often used for plastic pyrolysis. The pyrolysis reaction time of plastics is relatively short, depending on the type of plastic, pyrolysis process and plastic pyrolysis equipment.

Tire Pyrolysis Process: The temperature of tire pyrolysis is generally 300-700 degrees Celsius. Tyre pyrolysis often uses gas burner heating or electric heating to provide a high and stable temperature. Due to its complex composition, the pyrolysis reaction time of tire pyrolysis is usually long, generally taking several hours or even longer.

Different Pyrolysis Products in Waste Pyrolysis

Pyrolysis Waste Plastic Products: The products of plastic pyrolysis are mainly pyrolysis oil, syngas and a small amount of solid residue. After simple purification, pyrolysis gas can be used as fuel gas to provide energy for the pyrolysis process.

Pyrolysis Oil From Plastic: Pyrolysis oil generally contains a higher proportion of aliphatic hydrocarbons, with lower acidity and better stability. Plastic pyrolysis oil has lower density and viscosity, making it easier to handle and process. Since plastics decompose more thoroughly during the pyrolysis process, the possibility of containing solid residues is low and the calorific value is higher.

Plastic pyrolysis oil is suitable for use as fuel or further refined into higher value products, such as gasoline, diesel.

Tire Pyrolysis Products: The products of tire pyrolysis include pyrolysis oil, pyrolysis gas, carbon black and steel wire. Carbon black can be used to make rubber products, pigments, activated carbon, etc. Steel wire can be recycled for use in the metallurgical industry.

Tire Pyrolysis Oil: Tyre pyrolysis oil contains a higher concentration of aromatic hydrocarbons and sulfur compounds, which makes it more acidic and less stable. The density and viscosity of tire pyrolysis oil are relatively high, and it may contain more solid residues. The calorific value of tyre pyrolysis oil is usually lower than that of plastic pyrolysis oil. This is because tire pyrolysis oil has a higher water content and contains impurities.

Tire pyrolysis oil from tyres can be used as fuel for industrial burners or as a raw material for further refining by distillation plant. However, due to the presence of sulfur and other impurities, the amount of pollutants emitted during combustion is relatively large. It needs to be treated with desulfurization and other treatments to be more environmentally friendly.

Difference between Plastic and Tire Pyrolysis Plant

Batch pyrolysis plant can be used to process baled waste plastic or whole tires. Batch pyrolysis equipment is characterized by batch processing, not continuous feeding like continuous type. Therefore, the design of the pyrolysis plant needs to consider the differences in raw material properties between plastics and tires. For example, plastics may be more polymers, while tires have rubber, steel wire, fiber, etc.

The tire pyrolysis oil has a higher viscosity and is prone to pipe clogging. Therefore, the heating system and pipeline design of tire pyrolysis equipment may be different, such as better insulation or anti-clogging measures.

In terms of the structure of the pyrolysis reactor, tire pyrolysis may require more wear-resistant materials because of steel wire scraps and carbon black particles. Plastic pyrolysis equipment may focus more on anti-adhesion because plastics tend to agglomerate after melting.

In the process of pyrolysis product treatment, plastic pyrolysis may produce more pyrolysis oil and syngas, requiring an efficient condensation system. The oil and gas produced by tire pyrolysis may contain more sulfur and particulate matter, requiring additional purification treatment. Therefore, in batch pyrolysis equipment, the design of exhaust gas treatment and tar collection system may be different.