When selecting waste tyre pyrolysis machine, companies need to comprehensively consider several key factors, such as equipment quality, production capacity, environmental performance, and after-sales service. This ensures the tire pyrolysis equipment meets their production needs and maximizes both economic and environmental benefits.

The waste tire pyrolysis machine uses pyrolysis technology to realize the resource utilization and treatment of tire waste. The final products such as pyrolysis oil and carbon black produced by the tire pyrolysis equipment can be used in many fields.

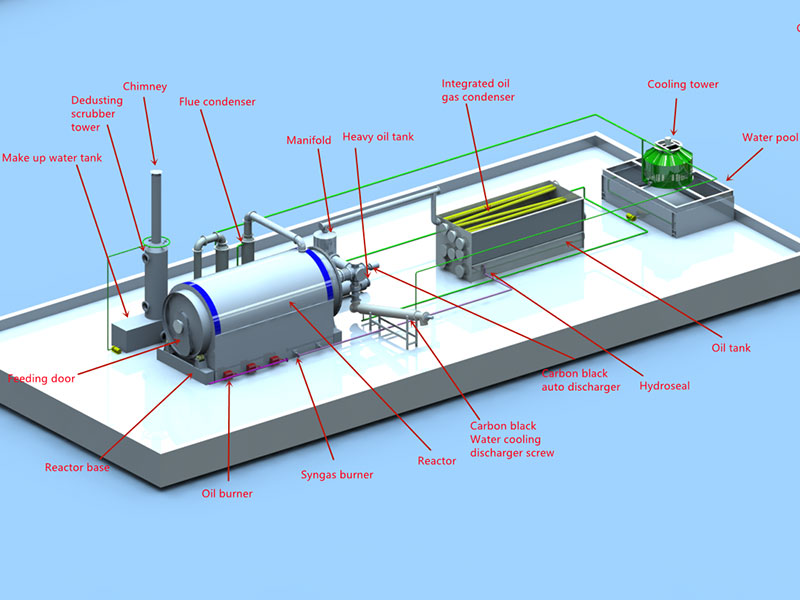

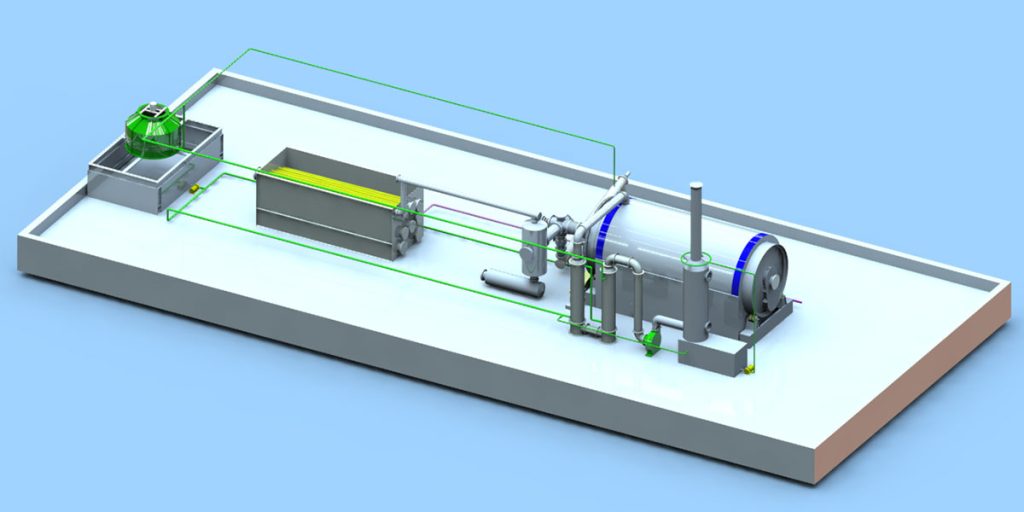

What are the Key Components of Waste Tyre Pyrolysis Machine? Feed system, pyrolysis reactor system, oil and gas condensation system, solid product discharge system, and exhaust gas treatment system.

Equipment Quality

Quality is paramount when choosing a waste tyre pyrolysis machine. High-quality pyrolysis machines are constructed from high-strength, high-temperature, and corrosion-resistant materials. Key components, such as the reactor, heating system, and condensing unit, should exhibit excellent performance and stability.

The reactor is the core component of the waste tire pyrolysis machine, and the material is the main factor affecting the tire pyrolysis plant cost. Waste tire pyrolysis reactors are typically constructed of 304 stainless steel (resistant to 600-700°C) or Q345R steel (resistant to 450°C).

The manufacturing process of the pyrolysis equipment is also crucial, ensuring overall equipment quality and reliability, extending its service life.

Waste Tyre Pyrolysis Machine Capacity

Production capacity is also a key factor. Tyre to Diesel Recycling Plant should select equipment with appropriate production capacity based on their production scale and market demand.

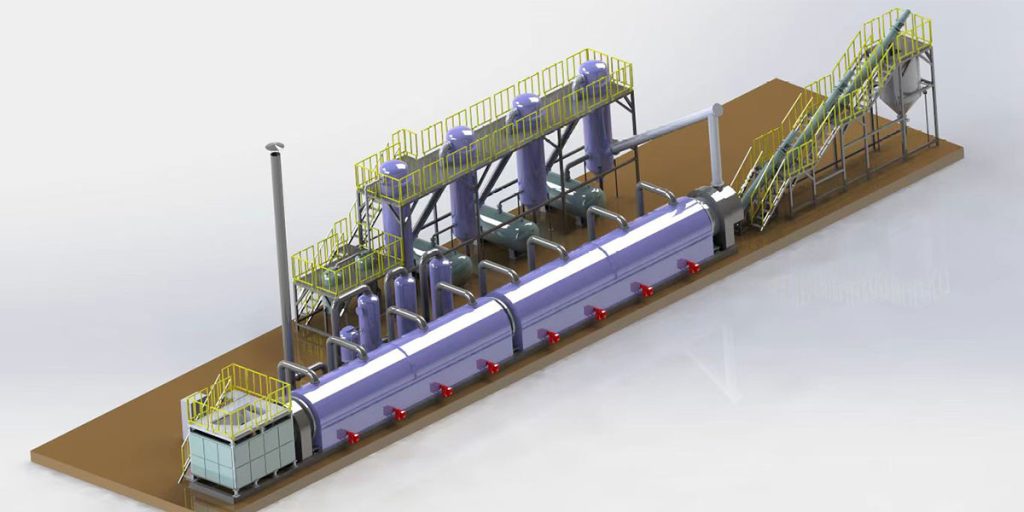

For example, large companies can choose continuous pyrolysis machines, which offer high efficiency and meet large-scale production needs. Mingjie Group provides MLL-20T and MLL-30 continuous waste tyre pyrolysis machines, with a processing capacity range of 25-40T/D.

Small companies can opt for batch or semi-continuous pyrolysis machines based on their specific needs. Mingjie Group offers MJ-6, MJ-10, MJ-12, MJ-15 batch pyrolysis plants, and MJL-15 semi-continuous pyrolysis plants. Their scrap tire processing capacity ranges from 6-15 tons/day.

The waste tire pyrolysis machine features a flexible component layout and modular design. This allows customers to customize the configuration, such as the feeding system, based on site conditions and production requirements. The feeding system can be divided into three types: manual, hydraulic, and screw feeding.

The continuous pyrolysis machine equipped with spiral feed is needed to process tires into rubber powder. Tire crushing equipment can achieve functions, such as tire cutting, crushing, and wire removal.

We provide waste oil distillation equipment further purifies the pyrolysis oil through distillation reaction. The tire pyrolysis oil is converted into non-standard diesel, which has higher utilization and commercial value.

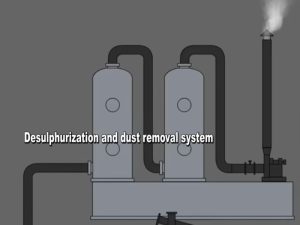

Environmental Protection System

Environmental protection systems are particularly important in Waste Tyre Pyrolysis Machine. Advanced waste tire pyrolysis plants are equipped with efficient exhaust gas treatment systems that purify exhaust gases generated during the pyrolysis process. These systems remove harmful substances and ensure emissions meet environmental standards.

To meet the high emission standards in some regions, Mingjie Group provides high-end exhaust gas treatment equipment. The treated exhaust gas can meet EU standards.

After-sales Service

Complete after-sales service for Waste Tyre Pyrolysis Machine is also essential. A reliable pyrolysis plant supplier will provide comprehensive after-sales support, including equipment installation and commissioning, operator training, regular maintenance, timely troubleshooting, and an adequate supply of spare parts.

Henan Mingjie Environmental Equipment Co., Ltd is a high-tech environmental enterprise, covering R&D, manufacturing , sales and exporting, We are committed to provide comprehensive solution for solid waste recycling, specializing in waste tires, waste plastics, and oil sludge reprocessing equipment, to get fuel oil and other renewable energy.

With more than 20 years manufacturing experience, a professional team for foreign trade and after-sale service, we take “ To Create Sustainable value for clients “ as pursuit. With abundant experience and foreseeing ability of this industry, we will continuously provide excellent service for clients.

All the products from Mingjie have been certified by CE and ISO, have been exported to Canada, Ireland, Czech Republic, Egypt, Brazil, Philippines, Korea, Jordan, Thailand, Malaysia, and England etc, has very stable clients and good reputation in Chinese market, Mingjie company will continuously to create value for our clients , strive to be the No.1 in the industry.