Pyrolytic carbon black (PCB) is a black powder obtained by separating and purifying the pyrolysis products of waste rubber or plastic. Pyrolytic carbon black is a key product in the resource recovery of solid waste. Its core component is carbon (70%-95%), along with small amounts of ash, volatile matter, and residual rubber/plastic cracking products.

Pyrolysis plant can reduce the pollution caused by landfill incineration of waste rubber/plastic while producing PCB, thereby reducing reliance on petroleum-based carbon black.

Scrap tire pyrolysis is currently a popular method for treating waste tires. Scrap tire pyrolysis plant can pyrolyze waste tires into tire oil, carbon black, steel wire, and combustible gas. Carbon black accounts for 30%-35% of the products, making it the second largest product of tire pyrolysis.

Tire Pyrolytic Carbon Black

Global production of pyrolytic carbon black (PCB) has shown significant growth over the past few years. According to the latest statistics, global annual production of crude carbon black and recycled carbon black (rCB) from the pyrolysis of scrap tires has reached 1.2 million tons and 180,000 tons, respectively. This achievement is the result of the effective utilization of 4.5 million tons of scrap tires.

Carbon black from waste tire pyrolysis has broad application prospects. Furthermore, its low cost meets the needs of sustainable development and overcomes the geographical and seasonal limitations of biochar production.

Carbon black is primarily composed of charcoal, along with trace amounts of hydrogen, oxygen, and nitrogen. The pyrolytic carbon black produced from waste tire is a black, solid powder, also known as “crude carbon black,” which can be reused.

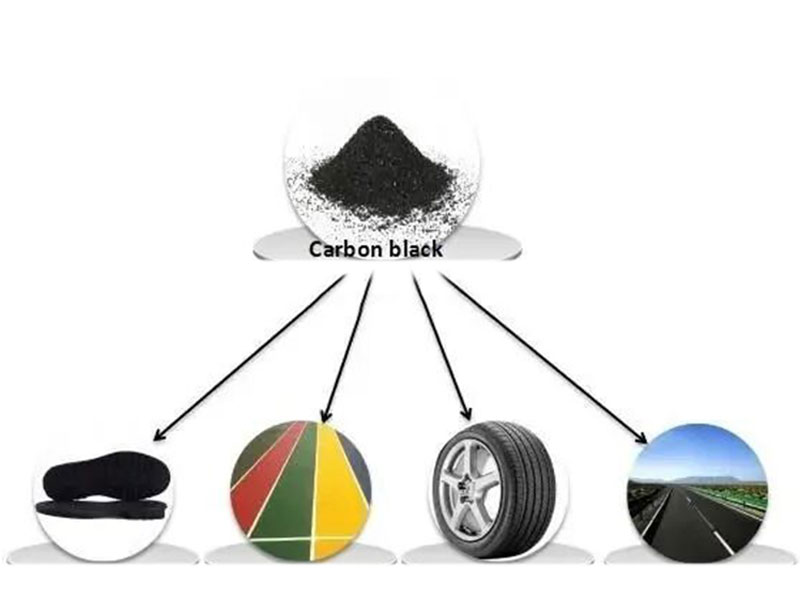

Properly treated and properly processed, crude carbon black has high economic value. It can be used as a reinforcing agent and filler in rubber products, including tires. Tire pyrolytic carbon black enhances the strength, durability, and colorability of rubber products. Therefore, it is often used as a raw material in various industries and fields.

There are several recycling methods for tyre pyrolysis carbon black:

- Carbon black from tyre pyrolysis can be made into pelletized carbon black and briquettes for heating and combustion, with a calorific value comparable to coal.

- Tyre pyrolysis Carbon black can be further processed and ground into powder.

- Carbon black can be processed into masterbatch and sold to the plastics industry for coloring. Carbon black pigments are excellent for coloring plastics.

In addition, tyre pyrolysis carbon black has many other uses, such as road paving, and possesses significant potential.

Advantages of Waste Tyres Pyrolysis

Traditional methods for the disposal and reuse of waste tires include open-air dumping, landfills, retreading and recycling, dock reefing, recycled rubber and rubber powder, and incineration. The vulcanization process in rubber tire production significantly enhances the tire’s tensile strength, wear resistance, chemical resistance, and thermal stability, making it difficult to biodegrade and process. This makes traditional waste tire disposal methods inefficient and difficult to address secondary pollution.

Unlike traditional methods for the disposal of waste rubber tires, pyrolysis not only recovers petroleum derivatives but also the carbon black and steel wire used in tire manufacturing. This recovery of nearly all components has made pyrolysis of waste rubber tires a highly sought-after method.

Regarding the pyrolysis products of waste rubber tires, the collection and processing of pyrolysis gas and pyrolysis oil are relatively mature. However, carbon black from tire pyrolysis is gaining increasing attention due to its complex composition and diverse applications.

Pyrolysis of scrap tires is currently one of the most effective ways to address waste tire pollution and recycle resources. This carbon black can be further processed and utilized as a carbon black substitute. Compared to traditional carbon black production, this process can significantly reduce carbon emissions by approximately 80%.

According to statistics, 89.5% of global carbon black consumption is consumed by the rubber industry, with tyre pyrolysis carbon black accounting for 67.5%. Traditional carbon black production is energy-intensive and highly polluting. Finding sustainable carbon black alternatives that can save energy and reduce carbon emissions is a major concern for the rubber industry.

Utilizing carbon black from scrap tire pyrolysis has practical implications for the rubber industry, including resource conservation, environmental protection, and carbon emission reduction.