Advanced recycling encompasses innovative technologies that go beyond mechanical recycling. Pyrolysis, one of the more established forms of advanced recycling, appears poised for growth in the coming years. Pyrolysis technology uses heat between 300°C and 600°C in the absence of oxygen to decompose various waste products, such as plastics, municipal solid waste, tire rubber, and biomass feedstock. Plastic energy pyrolysis uses heat to break down plastics, transforming and reconstructing their molecular structure.

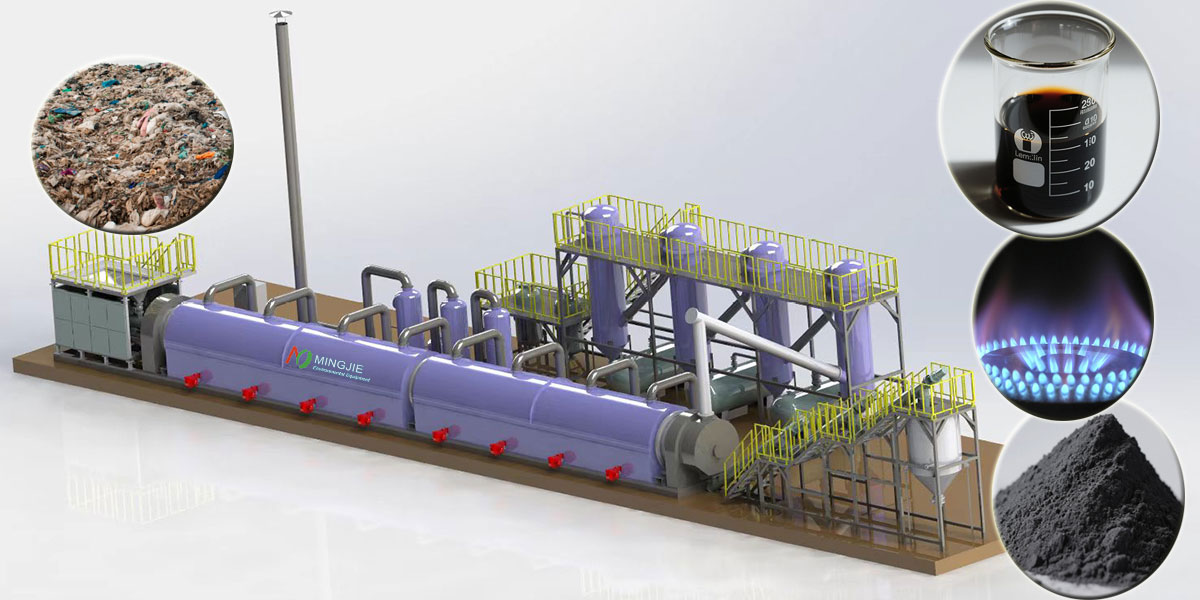

The main products of plastic pyrolysis are pyrolysis oil, syngas, and carbon black. Pyrolysis oil can be used in second-life plastic products or refined into products such as gasoline and diesel in pyrolysis oil distillation plants. Furthermore, syngas extracted from pyrolysis can be further processed to produce renewable hydrogen.

Plastic energy pyrolysis can address the landfill and pollution problems of plastic waste. Plastic pyrolysis plant converts waste plastics into high-value-added energy products – fuel oil, carbon black, and syngas. It can also reduce reliance on fossil fuels for transportation, and plastic pyrolysis oil provides a renewable alternative for industrial applications.

Major Corporate Investments in Plastic Energy Pyrolysis Projects

Oil majors and large chemical companies are eyeing plastic energy pyrolysis projects as they look to integrate renewable feedstocks into their processes.

Since 2019, Shell has invested in pyrolysis technology to reduce plastic waste. That same year, Shell’s Energy and Chemicals Park in Norco, Louisiana, USA, began using fuel oil produced through plastic energy pyrolysis. In November 2019, Shell announced an ambitious goal: to use 1 million tons of plastic waste annually across its global facilities by 2050.

A new pyrolysis oil upgrader is being added to Shell Chemicals Park Moerdijk in the Netherlands. The upgraded capacity will be 50,000 tons per year, with production expected to begin in 2024. In 2023, Shell announced several strategic collaboration agreements to improve access to plastic waste feedstock and enable long-term storage of pyrolysis oil.

Since December 2022, ExxonMobil has been operating an advanced plastic pyrolysis recycling plant in Baytown, Texas, USA. The pyrolysis plant is one of the largest in North America, with a capacity to process 80 million pounds of plastic waste annually. ExxonMobil announced plans to build a second advanced recycling unit at the Baytown facility to address growing demand for recycling.

In Malaysia, Petronas Chemicals Group Berhad (PCG) is expanding its plastic waste chemical recycling capabilities by converting end-of-life plastics into pyrolysis oil. In October 2023, PCG announced it had reached a final investment decision to build a 33 kg/year plastic waste pyrolysis plant in Pengerang, Johor. The plastic pyrolysis plant is expected to be operational in the first half of 2026.

Neste, a leading producer of sustainable fuel and renewable raw material solutions, has invested €111 million to build capacity at its Porvoo refinery in Finland to upgrade 150,000 tons of waste plastic into high-quality petrochemical feedstock. This plastic energy pyrolysis project has received support from the EU Innovation Fund and is expected to be completed in the first half of 2025.

In China, Sinopec is constructing a cotton field agricultural film recycling project at the Tahe Refinery. This project is my country’s first 10,000-ton-scale continuous pyrolysis industrial demonstration project for waste plastics. With a total investment of ¥162 million, the plastic recycling project uses pyrolysis technology to break down waste plastics into fuel oil, carbon black, combustible gas, and other products.

Continuous Pyrolysis Plant Manufacturer – Mingjie Group

Mingjie Group is a professional pyrolysis plant manufacturer in China. With over 20 years of experience in equipment manufacturing, we provide one-stop solutions for plastic energy pyrolysis.

Mingjie company offers skid-mounted small-scale pyrolysis equipment, batch pyrolysis plants, and continuous pyrolysis plants. We provide advanced exhaust gas purification systems and intelligent control systems, effectively addressing the current bottlenecks in physical recycling and the utilization of waste plastics.

Currently, Mingjie pyrolysis plants have been proven in multiple tire and plastic pyrolysis demonstration projects in South Korea, Thailand, the Philippines, and Vietnam. Mingjie plastic pyrolysis plants offer significant advantages in technological maturity, equipment reliability, cost-effectiveness, and international recognition.