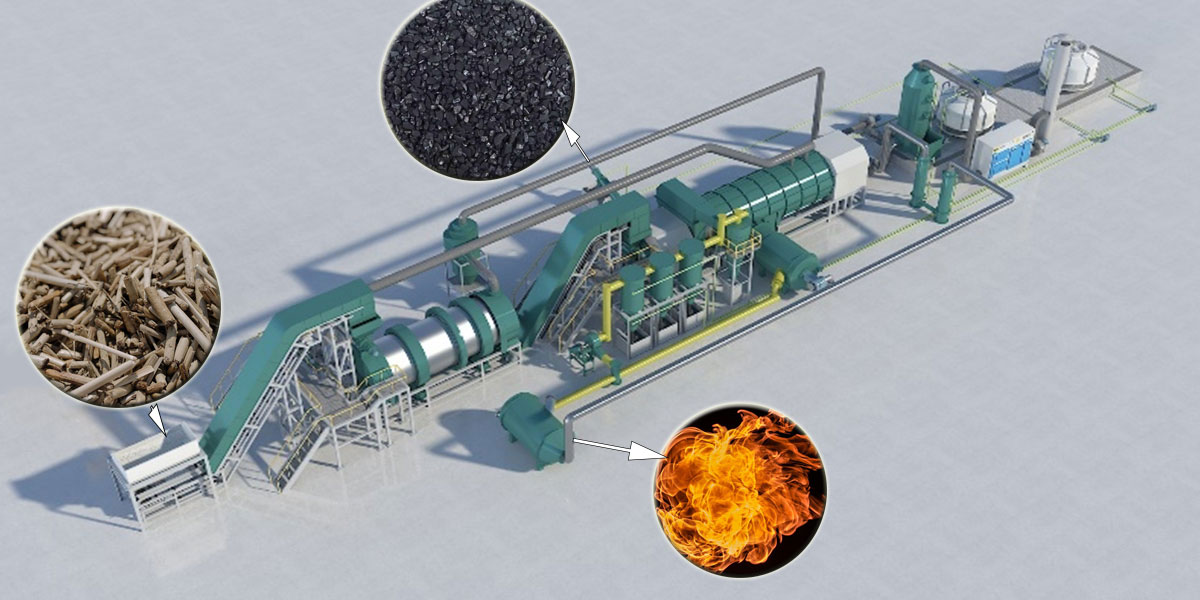

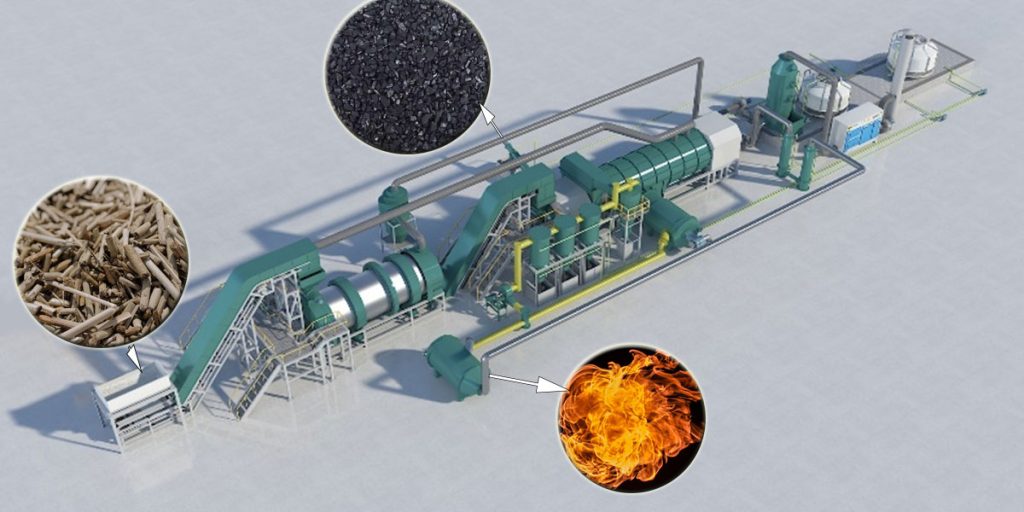

Biomass carbonization equipment has a positive impact on carbon sinks. It converts waste biomass into biochar through continuous pyrolysis technology, thereby reducing greenhouse gas emissions.

Biomass carbonization equipment can process a variety of waste biomass, such as crop straw, forestry waste, and livestock manure, converting it into biochar with both economic and ecological value, thus achieving resource recycling.

Waste biomass, processed by carbonization equipment, becomes an important material for soil conditioners, adsorbents, and energy feedstocks. Biomass to biochar production equipment promotes resource recycling and achieves efficient carbon sequestration.

Efficient Carbon Sequestration, Increases Carbon Sink Storage

During operation, biomass carbonization equipment converts biomass into biochar through pyrolysis, a process that efficiently fixes carbon. Biochar is rich in carbon, and its unique physical and chemical structure makes it extremely stable in the soil, allowing it to store carbon for long periods of time.

Compared to conventional biomass decomposition processes, biochar produced by biomass carbonization equipment is more resistant to microbial decomposition. This allows it to retain carbon in the soil for a long time, forming a stable carbon reservoir and significantly increasing carbon sink capacity.

Related research shows that for every ton of biochar added, approximately 0.5-0.8 tons of additional carbon is fixed in the soil. This data clearly demonstrates the significant effect of biochar in increasing carbon sink capacity.

Reduce Greenhouse Gas Emissions, Assist in Carbon Sequestration

If biomass is not carbonized, it may release significant amounts of greenhouse gases through natural degradation or incineration. When biomass degrades naturally, microbial decomposition converts the carbon it contains into greenhouse gases such as carbon dioxide and methane, which are released into the atmosphere. Incineration, however, releases a significant amount of carbon in the form of carbon dioxide over a short period of time, exacerbating the greenhouse effect.

Biomass carbonization plant changes this situation. During the pyrolysis carbonization process, the carbon in the biomass is converted into biochar and fixed there. The resulting syngas can be used as an energy source rather than being released directly into the atmosphere.

Biomass carbonization equipment operates under oxygen-free or low-oxygen conditions. Even if a small amount of greenhouse gases is produced, the emissions are significantly reduced compared to natural degradation and incineration.

Research shows that using biomass carbonization equipment to process biomass can reduce greenhouse gas emissions by approximately 30% to 50% compared to traditional treatment methods. This plays a significant role in mitigating global climate change and contributing to the growth of carbon sinks.

Biomass Carbonization Equipment Applications

Based on current applications, biomass carbonization equipment plays a vital role in multiple sectors, including energy, agriculture, and environmental protection.

In the energy sector, biochar, a clean, renewable energy source. It can be directly burned for power generation or heating. Some remote areas use biomass carbonization equipment to convert abundant local biomass resources into biochar, which is then used in small power stations to provide electricity and heat to local residents, achieving energy self-sufficiency.

Biomass carbonization machine can also be used as an additive to carbon-based fuels, improving the combustion efficiency of traditional fuels. Adding an appropriate amount of biochar to coal not only ensures more complete combustion but also increases its calorific value.

In the agricultural sector, biomass carbonization equipment facilitates the resource utilization of agricultural waste. Agricultural waste such as crop straw and fruit shells, after carbonization, becomes a high-quality soil conditioner. Biochar improves soil permeability and water retention, enhancing soil fertility. Biomass charcoal also absorbs heavy metals and harmful substances in the soil, reducing their harm to crops.

In the environmental protection sector, biomass carbonization equipment offers a new solution for waste treatment. Mingjie biomass carbonization plants can also process waste such as sludge from municipal sewage treatment plants and manure from livestock and poultry farms, achieving waste reduction, harmlessness, and resource utilization.