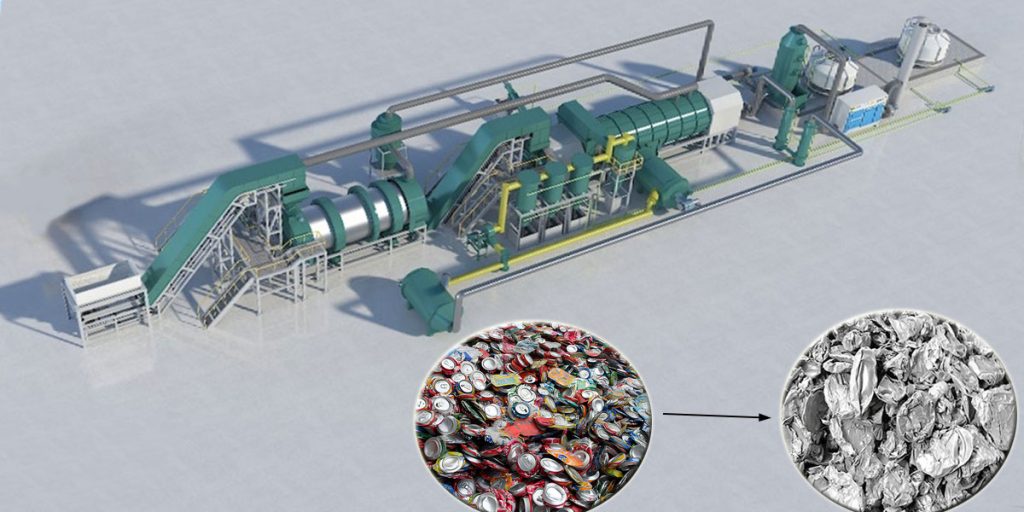

Biomass carbonization equipment can not only convert waste biomass into biochar, but also remove paint from metal cans. Therefore, biomass carbonization equipment is also called metal cans depainting machine.

Traditional paint removal methods for aluminum cans include chemical immersion and mechanical polishing. These methods not only waste resources but also pose significant threats to the environment and human health. Pyrolysis carbonization technology offers a new solution to the paint removal problem of aluminum cans. It is a more efficient, environmentally friendly, and safer method.

Continuous pyrolysis carbonization technology is a highly efficient and environmentally friendly processing method widely used for paint removal and recycling of materials such as aluminum beverage cans. Biomass carbonization equipment not only improves aluminum recovery rates but also reduces production costs, becoming an important solution in the aluminum can recycling field.

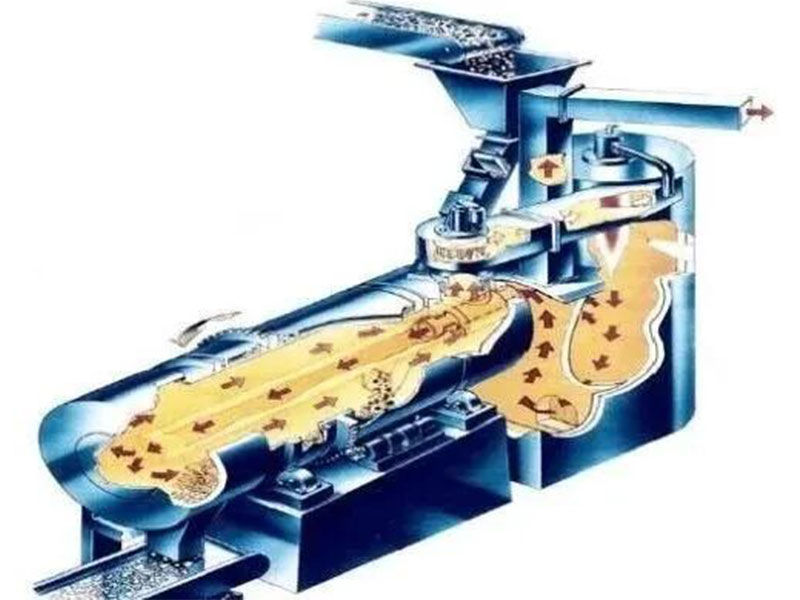

The metal cans depainting machine heats materials in an oxygen-deficient or low-oxygen environment, causing the organic coating on the surface to decompose and peel off.

How to Remove Paint from Metal Cans by Pyrolysis Carbonization?

The entire process of Metal Cans Depainting Machine can be divided into the following key stages:

Drying and Preheating Stage: In this stage, the material undergoes preliminary treatment at temperatures ranging from room temperature to 130°C. The preheating stage primarily involves evaporating internal moisture, preparing the material for the subsequent pyrolysis process.

Volatile Matter Analysis Stage: When the temperature rises to 130°C to 450°C, the organic matter gradually decomposes under the influence of heat, releasing volatile gases. This stage is crucial for coating removal.

Carbonization Stage: When the temperature exceeds 450°C, the coating on the material surface begins to completely decompose and peel off. Clean aluminum is exposed, laying the foundation for subsequent recycling.

Factors Affecting Paint Removal from Metal Cans

Temperature and an oxygen-deficient environment are two key factors in the paint removal process of metal cans by pyrolysis carbonization.

Temperature

Temperature is one of the core elements of pyrolysis carbonization. Generally, the suitable temperature range for pyrolysis aluminum can paint is between 450 and 800℃.

When the temperature is below 450℃, the organic matter in the paint layer decomposes slowly. It may even fail to decompose completely, resulting in incomplete paint removal. Some paint remains on the aluminum can surface, affecting subsequent recycling.

When the temperature is too high, exceeding 800℃, although the paint layer can decompose rapidly, the aluminum can itself faces the risk of oxidation. This reduces the purity and quality of the aluminum. Experiments have shown that raising the temperature to 900℃ resulted in significant oxidation on the aluminum can surface, significantly reducing the quality of recycled aluminum products.

Therefore, precisely controlling the temperature within the appropriate range is crucial to ensuring efficient paint removal in metal cans depainting machine.

Oxygen-Deficient Environment

An oxygen-deficient environment also plays an indispensable role in the pyrolysis process.

Under oxygen-deficient conditions, the combustible gases produced by paint decomposition can avoid a violent combustion reaction with oxygen. If the carbonization equipment takes place in an oxygen-rich environment, the combustible gases will react rapidly with oxygen and burn immediately upon generation. This not only fails to achieve energy recovery and utilization but may also cause safety problems.

At the same time, an oxygen-deficient environment can reduce the possibility of aluminum cans being oxidized at high temperatures, protecting the integrity and purity of the aluminum can substrate.

To create an oxygen-deficient environment, sealed metal cans depainting machine is usually used. Inert gas is introduced into the pyrolysis equipment to reduce the oxygen content to an extremely low level, creating favorable conditions for pyrolysis carbonization reaction.

Advantages of Metal Cans Depainting Machine

High-efficiency processing: The metal cans depainting machine adopts continuous pyrolysis design, enables the equipment to process large volumes of materials. This significantly improves production efficiency and meeting large-scale recycling needs.

Environmentally friendly and energy-saving: The pyrolysis and carbonization processes effectively reduce the emission of harmful substances, while recovering pyrolysis gases and bio-oils, improving resource utilization.

Quality control: Segmented heating technology ensures precise temperature control at each stage. Thereby it can guarantee pyrolysis processing effectiveness and the quality of the final product.