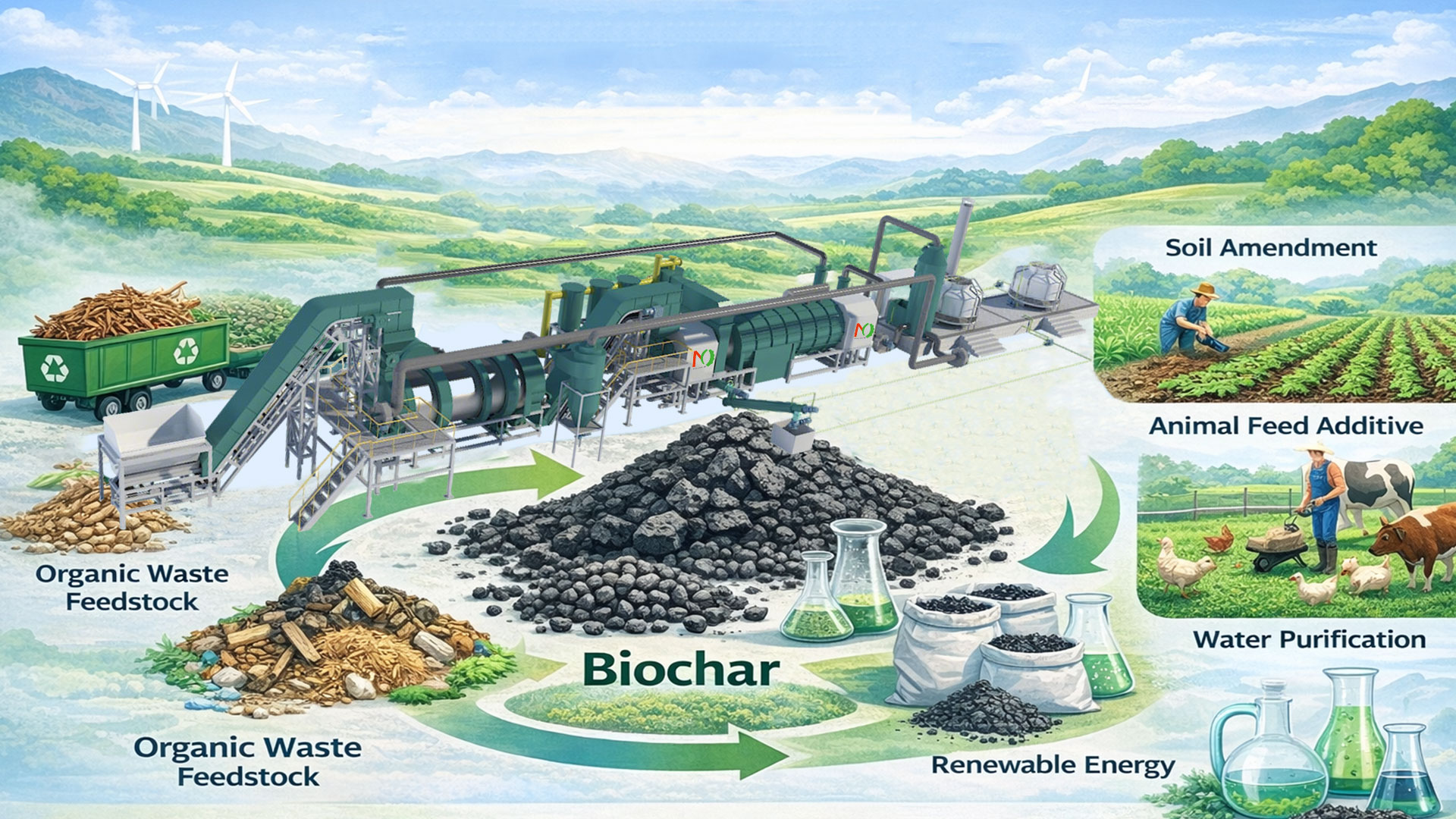

Continuous biochar production equipment is a crucial link connecting biomass resource utilization with the negative carbon economy. It not only achieves high-value conversion of waste biomass to biochar, but also provides a practical technological solution for sustainable development.

With the advancement of global carbon neutrality goals, continuous biochar production is moving from demonstration projects to large-scale commercialization. Its value extends beyond the biochar product itself, encompassing multiple benefits, such as carbon credits, increased agricultural yields, waste reduction, and energy recovery.

Continuous biomass pyrolysis machine is key to the industrialization of biochar plant, enabling a continuous flow from raw material biomass input to biochar product output.

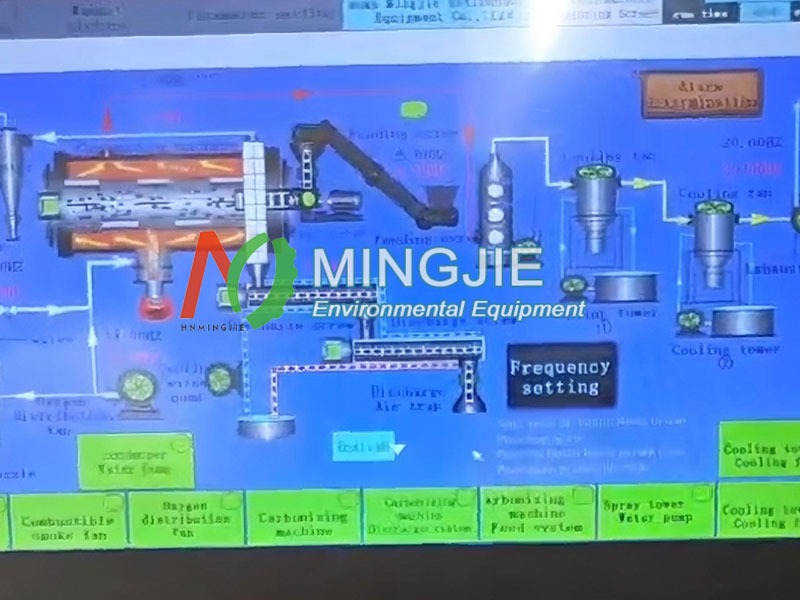

Continuous biochar production equipment operates 24 hours a day, significantly increasing the processing capacity of waste biomass. Simultaneously, efficient energy recovery and utilization, along with automated control, reduce labor and energy costs. The continuous, closed environmental system facilitates the integration of advanced flue gas treatment units, ensuring that emissions fully meet standards. The real-time monitoring and data recording system of the continuous biochar production line provides perfect support for generating carbon credits.

How is Continuous Biochar Production Achieved?

Mingjie biomass carbonization plant achieves continuous biochar production through continuous biomass pyrolysis technology. It is a complete biochar production line. It mainly includes a feeding system, drying system, pyrolysis and carbonization reaction system, condensation system, exhaust gas treatment system, and PLC control system.

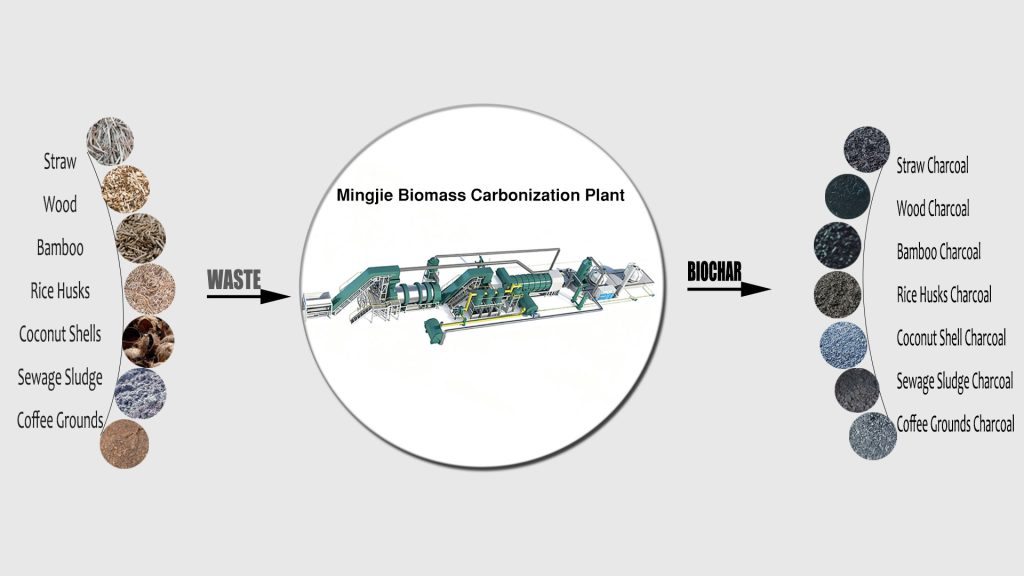

The selection of raw materials plays a decisive role in the quality and performance of biochar. Ideal biomass raw materials should have a high carbon content, low ash and moisture content, and good pyrolysis performance. Common high-quality raw materials include wood, straw, and rice husks.

When selecting wood, hardwoods (oak, maple) usually produce higher-quality biochar due to their higher carbon content and density. Straw is widely available and inexpensive, but may contain impurities and high moisture content. Rice husks have a unique physical structure, and the biochar produced from them exhibits special properties in certain applications.

Raw Material Pre-treatment

Pre-treatment is an important step in ensuring the continuous production of biochar.

First, crushing is necessary. For larger biomass raw materials, a crusher is needed to crush them into a suitable particle size. Generally, a particle size of less than 20 mm is required to ensure uniform heating during the subsequent carbonization process.

Secondly, drying is crucial. If the raw material has a high moisture content, it will increase energy consumption, reduce carbonization efficiency, and may also affect the quality of the biochar. Therefore, raw materials with high moisture content need to be dried, generally requiring a moisture content of less than 15%. In addition, for some raw materials with poor fluidity, granulation may be needed to improve their flowability.

Biomass Pyrolysis Carbonization Process

Pyrolysis carbonization are the core steps in the continuous production of biochar, and their operating parameters directly affect the yield and quality of the biochar. During the pyrolysis process, the heating rate and residence time must be strictly controlled.

A heating rate that is too slow will prolong the production cycle and reduce production efficiency. A heating rate that is too fast may lead to uneven pyrolysis of the biomass raw materials, affecting the quality of the biochar.

The residence time needs to be reasonably adjusted according to the characteristics of the raw materials and the performance of the carbonization reactor. This ensures that the biomass is fully pyrolyzed and converted into biochar.

Cooling and Collection of Biochar

The cooling process is crucial for maintaining the stable performance of biochar. Mingjie pyrolysis plants typically use water cooling to cool the biochar. Water cooling involves heat exchange between circulating water and the biochar, achieving rapid cooling. The collected biochar is then promptly packaged and stored, usually in sealed bags or containers.

Advantages of Continuous Biomass Pyrolysis Equipment

Continuous biomass pyrolysis equipment demonstrates significant advantages in several aspects.

From a production efficiency perspective, continuous biochar production equipment enables uninterrupted supply of biomass raw materials and continuous pyrolysis reactions. This allows biochar to meet the demands of large-scale industrialization and rapid market growth, promoting its widespread application in various fields.

In terms of cost control, continuous pyrolysis equipment reduces production costs by optimizing process flow and energy utilization. Continuous production reduces energy consumption during equipment startup and shutdown, improving energy efficiency.

Regarding product quality, continuous pyrolysis machine ensures the stability and consistency of biochar quality through precise control of production parameters. High-quality and stable biochar products can improve user effectiveness and satisfaction. This greatly helps to enhance market confidence in biochar and promote the healthy development of the biochar market.

Continuous biochar production complies with environmental policies and offers significant environmental benefits. The exhaust gas and wastewater generated during biochar production can be treated to meet emission standards. Some of the exhaust gas can also be recycled as fuel, achieving resource recycling and energy conservation and emission reduction.