In the world of wood processing, sawdust, these seemingly insignificant, fine debris, is an inevitable byproduct. In the past, it was often discarded as worthless waste, resulting in a significant waste of resources and a potential environmental burden. Sawdust charcoal machine can help realize the valuable value of sawdust by transforming it into biochar.

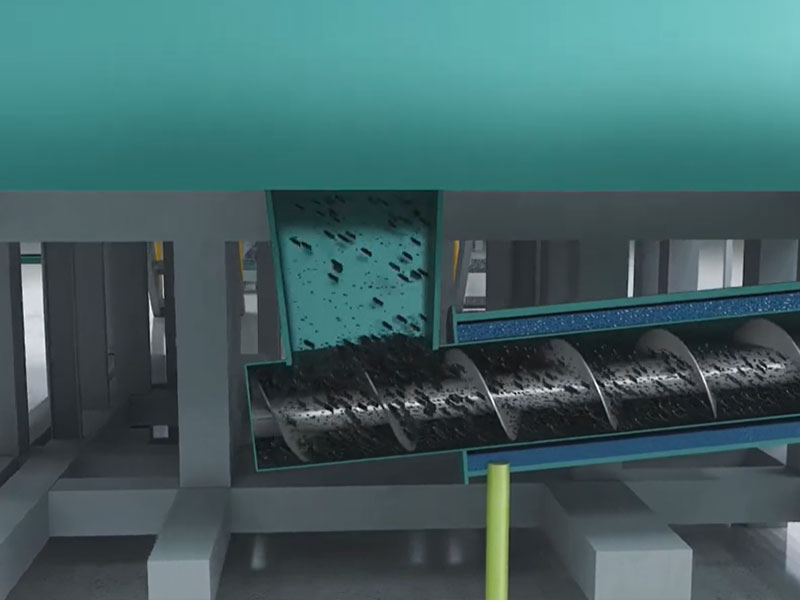

Originally scattered sawdust is collected and fed into the sawdust charcoal machine. Inside, it undergoes a series of miraculous transformations, becoming charcoal of multiplied value. This carbonization process imbues the sawdust with new life and value.

Among various charcoal making machine, the Mingjie sawdust charcoal machine, with its unique continuous pyrolysis technology and environmental advantages, holds an irreplaceable position.

Compared to traditional traditional charcoal-making methods, it is free from reliance on natural conditions and is no longer restricted by factors such as weather and site conditions, enabling stable and efficient charcoal production.

Unlike some charcoal making machine that can only process specific raw materials, the sawdust charcoal machine is highly adaptable to various raw materials. It can transform both softwood sawdust and harder hardwood sawdust into high-quality charcoal. This versatility makes Mingjie sawdust charcoal machine stand out in the charcoal making industry and the preferred equipment for many companies.

Working Principle of Mingjie Sawdust Charcoal Machine

Sawdust typically contains a certain amount of moisture. If this moisture is not removed, it will affect the carbonization effect during subsequent processing.

Pyrolysis carbonization of sawdust is carried out in an oxygen-free or low-oxygen environment. In the sawdust charcoal machine, the material is heated to high temperatures, typically between 400 and 800°C.

As the temperature rises, the moisture in the material is first completely evaporated, followed by the pyrolysis of organic matter. Components such as lignin and cellulose gradually decompose, producing combustible gases, such as carbon monoxide, hydrogen, and methane, tar, and carbon-rich charcoal.

As the pyrolysis reaction continues, the carbon content in the material increases. Other impurities are gradually removed, ultimately forming charcoal with a high fixed carbon content and excellent adsorption properties. The entire carbonization process requires strict temperature and time control to ensure charcoal quality and yield.

Sawdust Charcoal Machine Manufacturer

Sawdust charcoal machines are enjoying strong sales in the global market. As equipment that converts waste sawdust into high-value charcoal, sawdust charcoal machines are attracting increasing attention and favor in a growing number of countries and regions.

Mingjie Group is a sawdust charcoal machine supplier integrating R&D, manufacturing and sales. Our continuous biomass carbonization plant has a significant impact in both domestic and international markets, with exports to countries and regions such as Chile, South Africa, Vietnam, Tanzania, and Finland.

Advantages of Mingjie Biochar Making Machines

Sawdust charcoal making machines utilize advanced automation and efficient processing technology, enabling continuous production. We offer a variety of biochar production equipment models, including the MJT-100, MJT-500, MJT-1000, MJT-2000, MJT-3000, and MJT-5000.

Sawdust charcoal machines also demonstrate high energy efficiency. They fully utilize the heat generated during the sawdust forming and carbonization processes. Through a comprehensive heat exchange system, the charcoal making machine recycles this heat for use in drying and preheating the raw materials, significantly reducing energy consumption.

Charcoal making machines recycle waste sawdust, providing an effective solution to the waste problem in the wood processing industry. They use waste sawdust as raw material and, through a series of processes, transform it into economically valuable charcoal, achieving resource recycling. This not only reduces environmental pollution from waste but also creates additional economic benefits for businesses.

Sawdust charcoal making machines also produce low pollutant emissions during the production process. They utilize advanced exhaust gas treatment systems and environmentally friendly processes, effectively reducing the generation of waste gas, wastewater, and waste residue.

Sawdust biochar machines also produce charcoal with a high carbon content. This high carbon content ensures more complete combustion and produces less ash. This not only reduces the need for ash removal but also increases charcoal utilization.

Due to the strict control of process parameters and quality standards during biochar production, each batch of charcoal maintains a high degree of consistency in quality.