Tire to Oil Plant Turns Rubber into Fuel

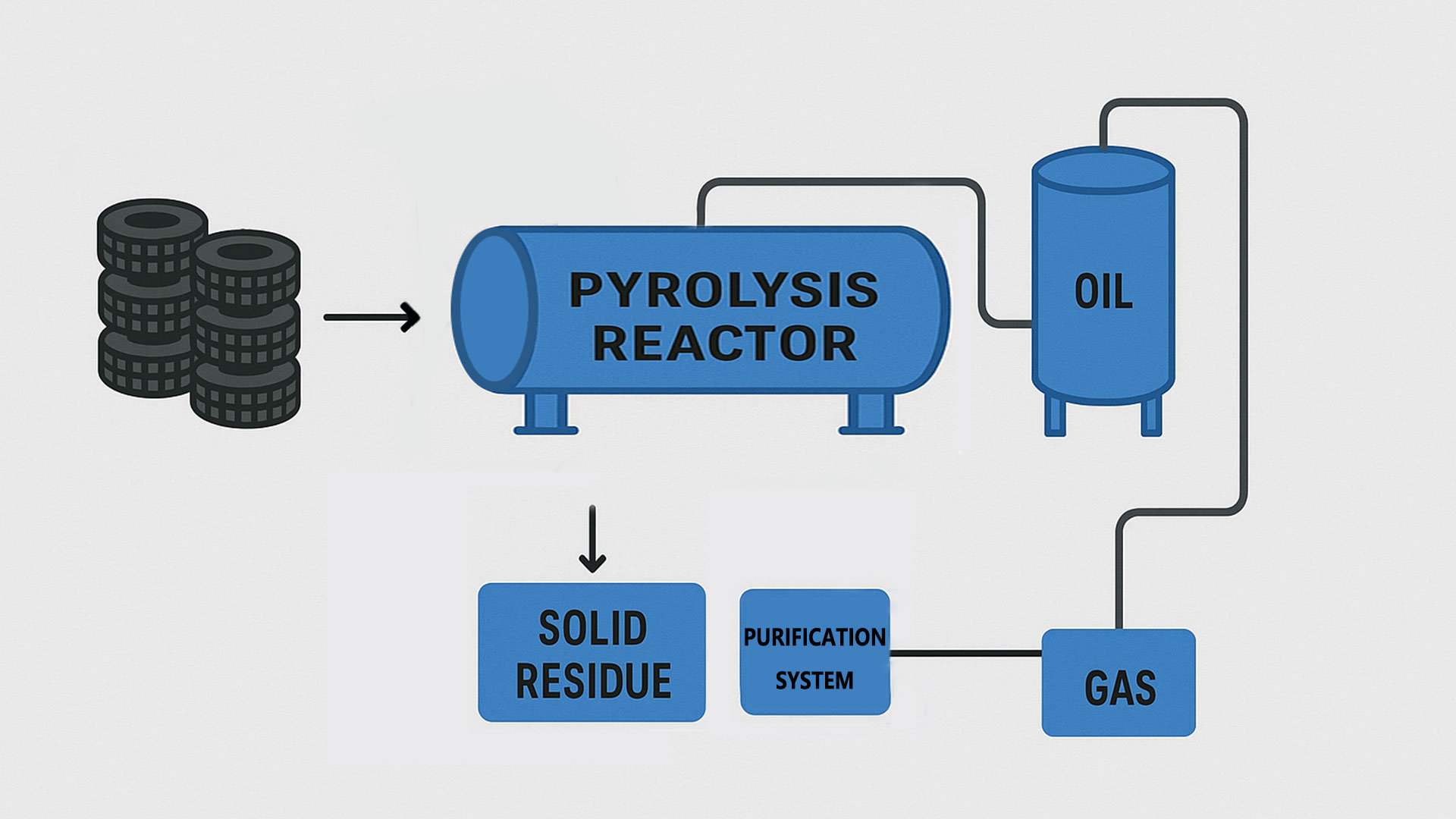

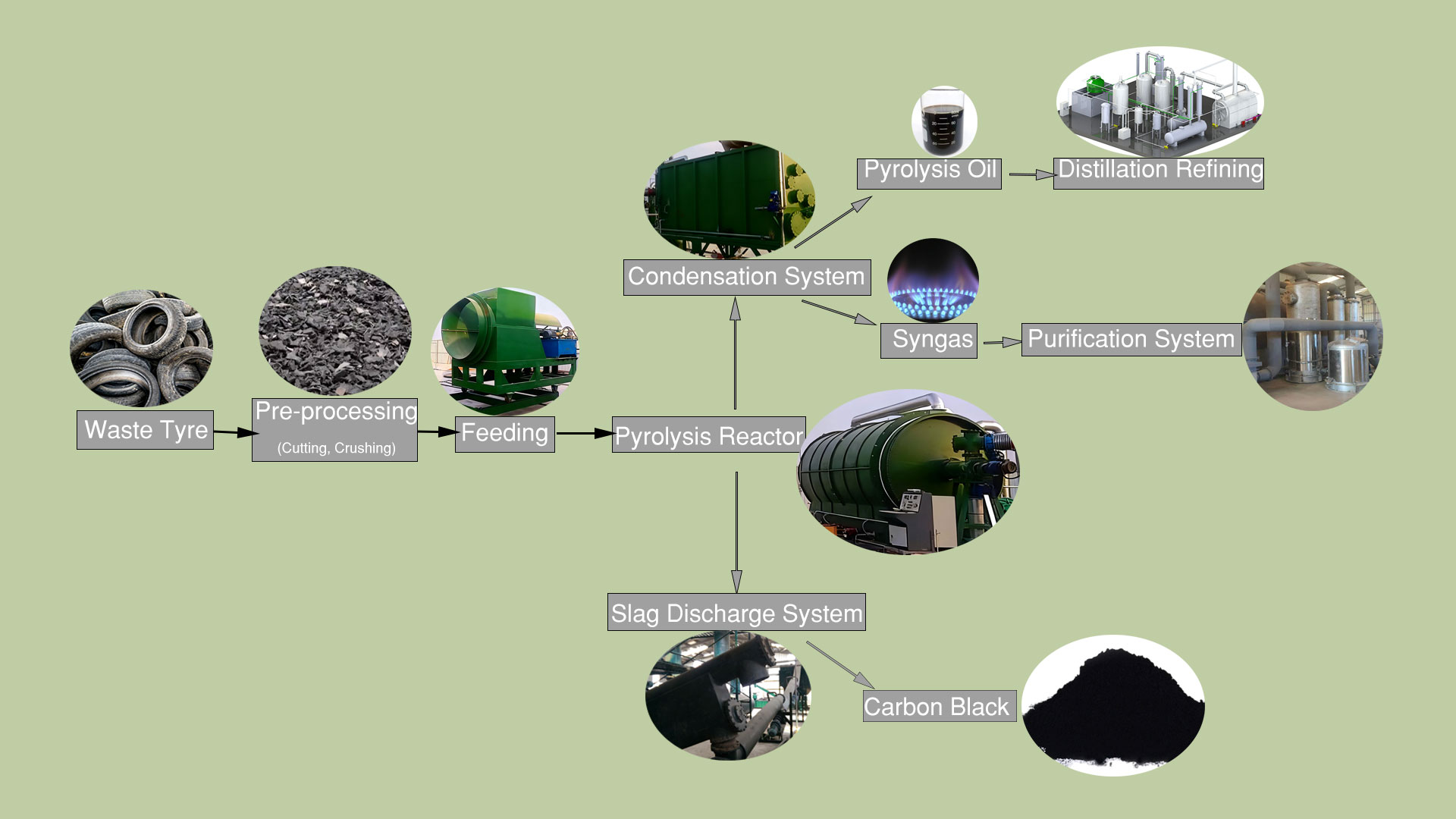

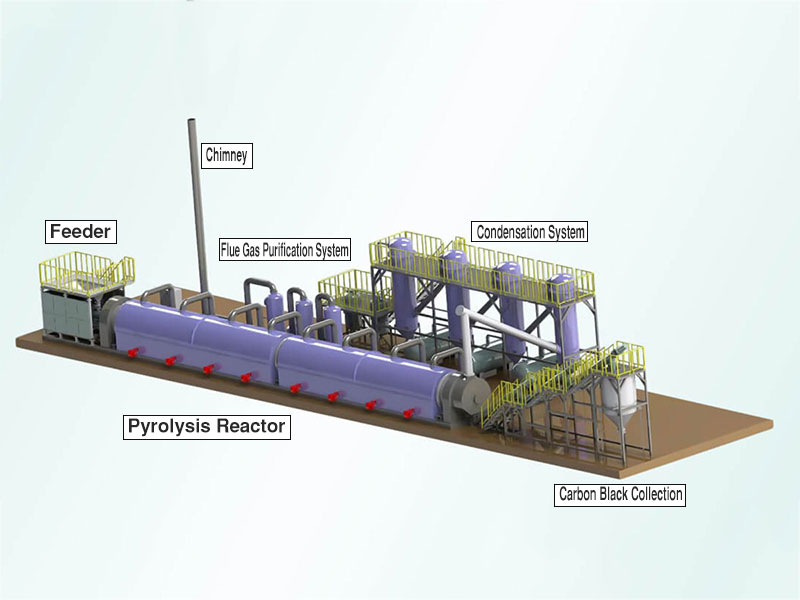

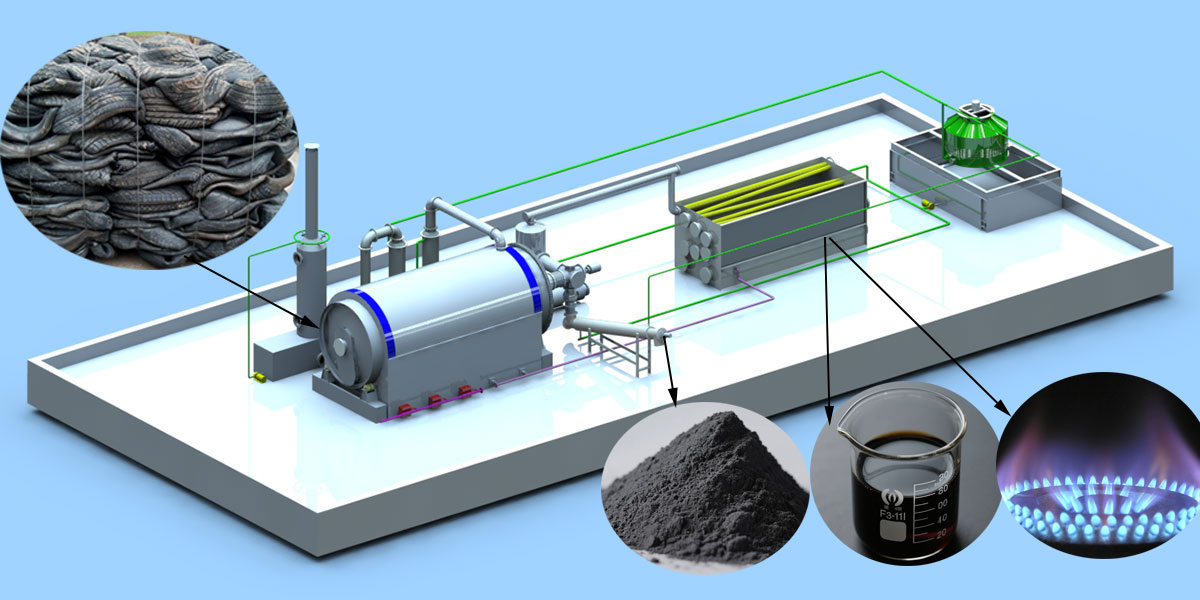

The tire to oil plant is an industrial facility specifically designed to convert waste tires into reusable resources. It plays an increasingly important role in resource recycling and environmental protection. The tire to oil plant operates on the principle of pyrolysis technology. This is a process that decomposes organic matter into smaller molecules at high … Read more