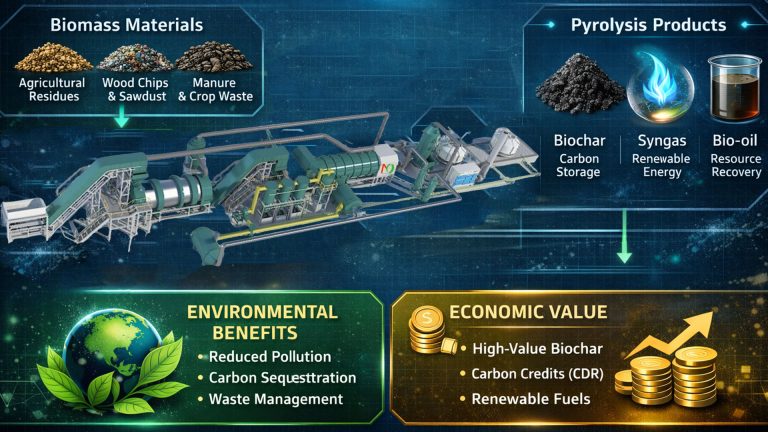

With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Biochar Manufacturing Equipment for Carbon Removal

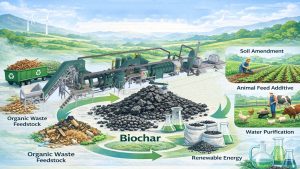

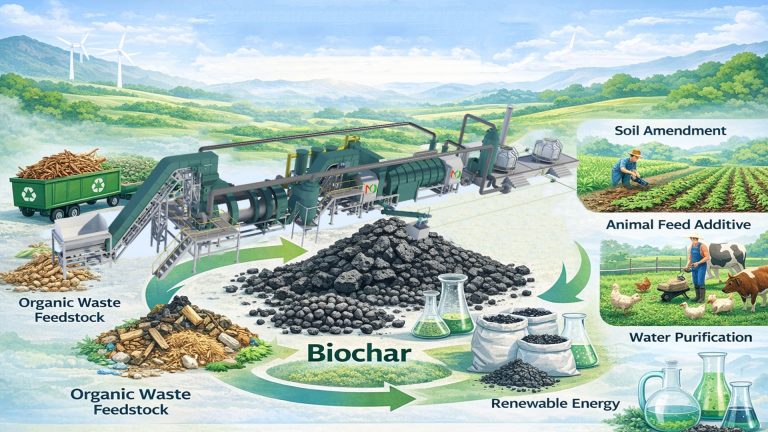

Mingjie biochar manufacturing equipment utilizes a continuous pyrolysis system. The slow pyrolysis process is designed to maximize fixed carbon yield. The biomass carbonization plant integrates multiple stages, including drying, pyrolysis, gas combustion, and product cooling. It achieves continuous biomass feeding and stable biochar production. Unlike biomass energy, biochar is produced

Animal Manure Pyrolysis for Clean Energy Transition

Animal manure has long been considered an environmental burden, but it is now poised to become a key resource in the clean energy transition. Chemical conversion technologies (especially manure pyrolysis) can transform manure into carbon-rich biochar. Studies have shown that pyrolysis technology can efficiently utilize cattle and poultry manure to

Carbonizer Machine for Waste Biomass Recycling

In the field of waste biomass resource recycling, continuous carbonizer machine is playing a crucial role. Mingjie biomass carbonizer machines have been successfully operating in biochar production projects in several countries, including South Africa, Chile, Saudi Arabia, and South Korea, receiving positive feedback. The biomass carbonizer machine is a core

Continuous Biochar Production Equipment for Sustainability

Continuous biochar production equipment is a crucial link connecting biomass resource utilization with the negative carbon economy. It not only achieves high-value conversion of waste biomass to biochar, but also provides a practical technological solution for sustainable development. With the advancement of global carbon neutrality goals, continuous biochar production is

Continuous Biomass Pyrolysis – Sustainable Solution

Continuous biomass pyrolysis is a key technology with significant environmental value, energy value, and carbon reduction potential. Through large-scale, continuous operation, biomass pyrolysis equipment provides a sustainable solution for biomass waste treatment. It continuously converts biomass into biochar, syngas, and bio-oil. Biochar is an important vehicle in the current carbon

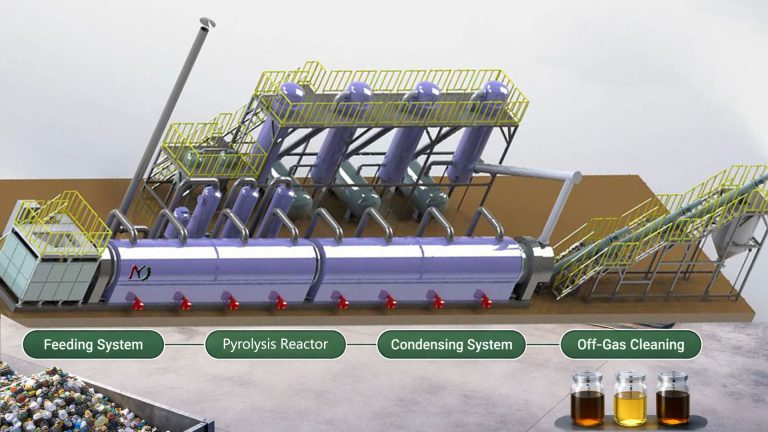

Continuous Plastic Pyrolysis – Low Carbon Solution

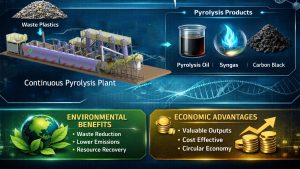

Continuous plastic pyrolysis, as a chemical recycling technology, is gradually becoming an important solution for plastic recycling and low-carbon transition. Continuous pyrolysis plants continuously convert waste plastics into pyrolysis oil, syngas, and solid residue, achieving resource utilization. Compared to batch processes, continuous plastic pyrolysis demonstrates more significant overall benefits in

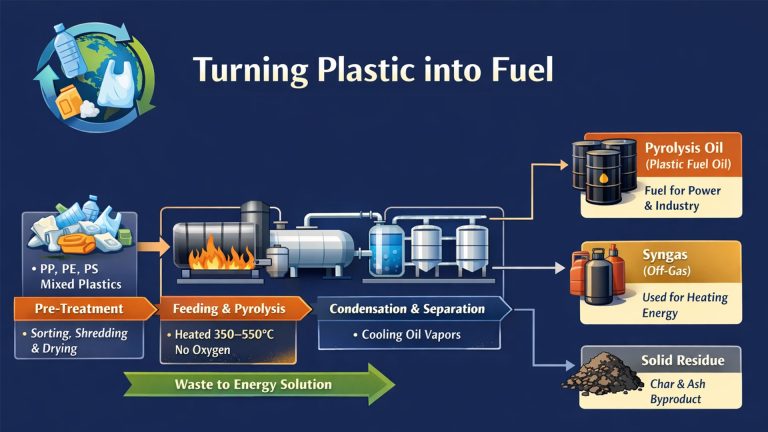

Waste Plastic to Fuel Conversion

The core of waste plastic to fuel conversion lies in reversing the polymerization process. Pyrolysis technology can transform these plastic wastes back into their original form—fuel. This offers a potential solution for closing the pollution loop. Plastics are long-chain polymers formed from small monomer molecules extracted from petroleum through polymerization

Continuous Waste Tyre to Oil Pyrolysis Plant

The continuous waste tyre to oil pyrolysis plant demonstrates exceptional environmental performance, making it a green pioneer in the field of waste tire processing. Its pyrolysis process takes place in a completely enclosed system, effectively placing an environmental shield over the entire process. This tightly controls potential pollution within the

Waste Plastic into Fuel Machine Market

In the waste plastic into fuel machine market, continuous pyrolysis machines hold a significant market share. The high efficiency and scalability makes them the preferred choice for large-scale plastic pyrolysis projects. Batch pyrolysis machines, due to their flexibility and lower investment costs, are attractive for smaller operations and pilot projects.

Turning Plastic into Fuel – Pyrolysis Waste to Oil

The core principle of turning plastic into fuel is pyrolysis technology. As a typical chemical recycling method, it is becoming an important solution connecting waste management and energy utilization. Due to its high efficiency, pyrolysis technology currently dominates the field of turning plastic into fuel (PTF) technology. By 2025, pyrolysis