With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

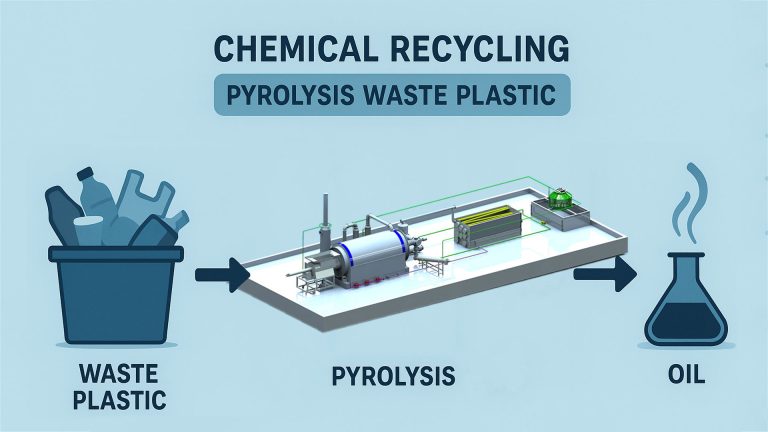

Chemical Recycling Pyrolysis Waste Plastic

Pyrolysis is the core technology of chemical recycling, which can convert waste plastics into fuel oil and achieve recycling. Compared to traditional landfill and incineration, chemical recycling pyrolysis is the most efficient and environmentally friendly method for solving waste plastic pollution problems. Pyrolysis Plant achieves zero toxic gas leakage and

Sludge Disposal Methods: From Pollution to Resource Transformation

With increasing environmental awareness and emphasis on sustainable development, sludge disposal methods are constantly evolving. Various advanced sludge treatment technologies have emerged, progressing from simple dewatering and landfilling to today’s diversified treatment methods such as anaerobic digestion, aerobic fermentation, drying and incineration, and pyrolysis carbonization. More and more wastewater sludge

Wood Chips Pyrolysis Machine for Energy Convertion

Wood chips pyrolysis machine can convert wood processing residues into high-value-added biochar. It shows broad application prospects in energy supply, soil improvement, and environmental pollution control. Wood chips, as one of the main wastes generated by the forestry and wood processing industries. They have long been mostly incinerated or discarded,

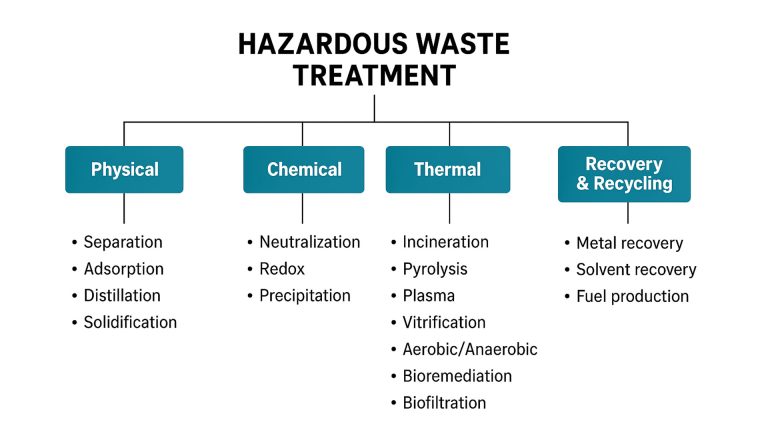

Hazardous Waste Treatment by Pyrolysis Technology

Advanced hazardous waste treatment technologies, including physical, chemical, and thermal processes, are transforming the landscape of waste management. Regulatory policies emphasizing waste reduction, recycling, and sustainable disposal practices are driving market growth. Governments worldwide are implementing stricter regulations to minimize environmental impact, leading to increased demand for hazardous waste treatment

How Biochar Projects Create Carbon Assets

Biochar is considered one of the most promising and uniquely valuable carbon assets. Unlike biocoal, which primarily relies on carbon substitution for emission reduction, the core value of biochar lies in its ability to achieve carbon removal or negative emissions. This is becoming increasingly valuable in the international community’s pursuit

Online Guidance for MJT-100 Mobile Biochar Production Equipment

On November 15, 2025, Mingjie Group provided online installation guidance and training for the Chilean customer on MJT-100 mobile biochar production equipment. Following the technicians’ instructions, the customer successfully mastered the operation of the biochar production equipment. Ultimately, the mobile biochar machine completed the conversion of biomass pellets into biochar.

Pyrolysis for Solid Waste Treatment Reduces Carbon Footprint

Pyrolysis for solid waste treatment has shown great potential in reducing carbon footprint. Among various waste treatment solutions, pyrolysis technology is becoming an important pathway to reduce carbon footprint and achieve resource recycling. Both landfilling and incineration of solid waste produce significant carbon footprints. Studies show that solid waste landfills

Solid Waste Pyrolysis Equipment: Turning Waste into Treasure

Faced with the surge in solid waste production and the severe pollution caused by traditional treatment methods, pyrolysis equipment has garnered significant attention as a green solution that turns waste into valuable resources. Solid waste pyrolysis equipment decomposes waste at high temperatures in an anaerobic or oxygen-deficient environment. It can

2025 Biochar Carbon Removal Market Data Analysis Report

From 2022 to the first half of 2025, the cumulative contracted volume of biochar carbon removal (BCR) credits reached 3.04 million tons. Among them, sales in the first half of 2025 alone reached 1.6 million tons. The average annual purchase volume per buyer increased from 542 tons in 2022 to

Petroleum Sludge Treatment by Pyrolysis Technology

Pyrolysis technology is characterized by its high efficiency, environmental friendliness, and resource recovery. It is considered one of the most promising technologies for petroleum sludge treatment and disposal. Petroleum sludge is one of the major hazardous solid wastes generated during petroleum extraction, transportation, refining, and storage. Oil sludge can come