With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Installation of MJ-12 Pyrolysis Plant in Egypt

On February 5, 2026, Mingjie Group completed the installation and commissioning of MJ-12 pyrolysis plant in Egypt. The pyrolysis plant can achieve the resource utilization and treatment of waste materials such as plastics, oil sludge, and tires. It has become the choice of many investors for waste recycling projects. The

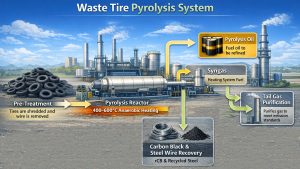

Waste Tire Pyrolysis System

The waste tire pyrolysis system, as a solution to the challenging problem of waste tire disposal, enables the resource utilization of waste tires. Through high-temperature decomposition, waste tires can be converted into various high-value products such as carbon black, pyrolysis oil, synthesis gas, and steel wire. Carbon black can be

Palm Kernel Shell Pyrolysis to Biochar Technology

Palm oil processing plants in Southeast Asia are mostly located in remote rural areas with insufficient power supply. Palm kernel shells, a readily available waste product in the region, can be converted into energy through pyrolysis technology, effectively addressing local energy supply problems. Compared to other biomass pyrolysis processes, palm

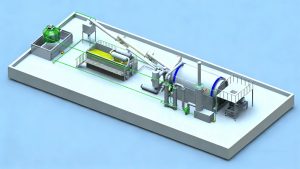

Small Scale Biochar Production Equipment for Sale

Small scale biochar production equipment is a compact device specifically designed and manufactured for small-scale production needs. It uses agricultural and forestry waste as its main raw material source, such as straw, wood chips, and fruit shells. Through a continuous pyrolysis process within the small scale biochar production equipment, these

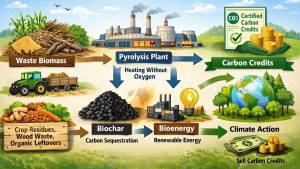

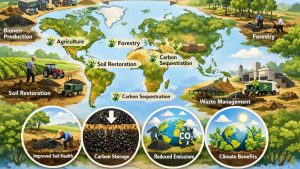

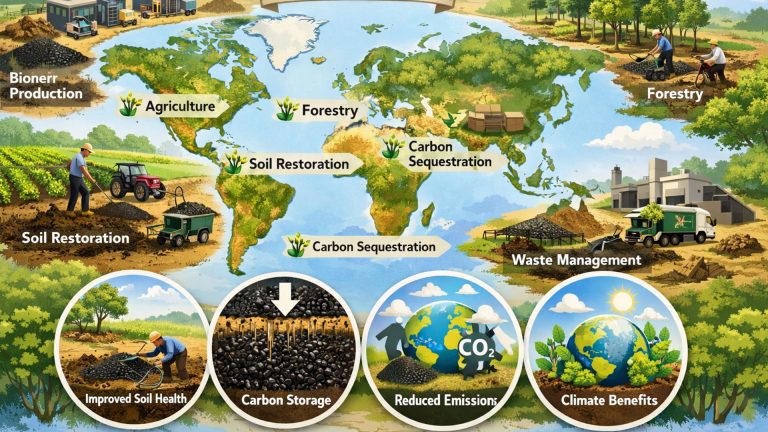

What is the Biochar Carbon Credit

Biochar carbon credit is becoming an important tool for addressing climate change and promoting sustainable agricultural development. It achieves long-term carbon sequestration by converting agricultural and forestry waste into stable carbonaceous materials, generating tradable carbon credits. In the past two years, the demand for biochar carbon credit has grown at

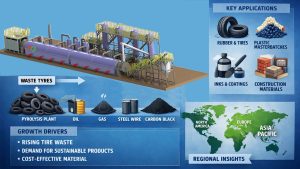

Semi Continuous Pyrolysis System for Waste Tyre Disposal

Market data shows that semi continuous pyrolysis system holds a prominent share in the segmented market of waste tire pyrolysis equipment. According to relevant industry research reports, semi-continuous pyrolysis devices are widely used in waste tire and plastic recycling due to their comprehensive performance advantages. They meet the needs of

2025 Waste Tyre Pyrolysis Carbon Black Market

In 2025, the global recycled carbon black market size from tire recycling reached US$91 million. This figure not only marks a significant achievement for the tire pyrolysis industry in solid waste treatment and resource recycling, but also foreshadows its vast development potential. In 2025, in terms of regional distribution, the

Global Biochar Market Outlook for 2026

The global biochar market is experiencing continuous expansion, driven by a focus on sustainable agricultural and environmental practices. The global biochar market size was US$859 million in 2025 and is projected to reach US$969 million in 2026, representing an annual growth rate of approximately 12.8%. The increasing applications of biochar

Plastic Pyrolysis Oil Market Price in 2025

In 2025, the pyrolysis oil market was valued at US$1.44 billion and is projected to grow from US$1.69 billion in 2026 to US$3.72 billion in 2031. Waste plastics accounted for 55.02% of the pyrolysis oil market share in 2025, while fuel accounted for 93.15% of the market size. The global

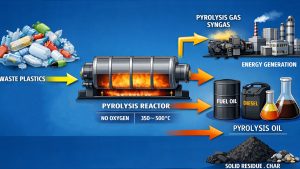

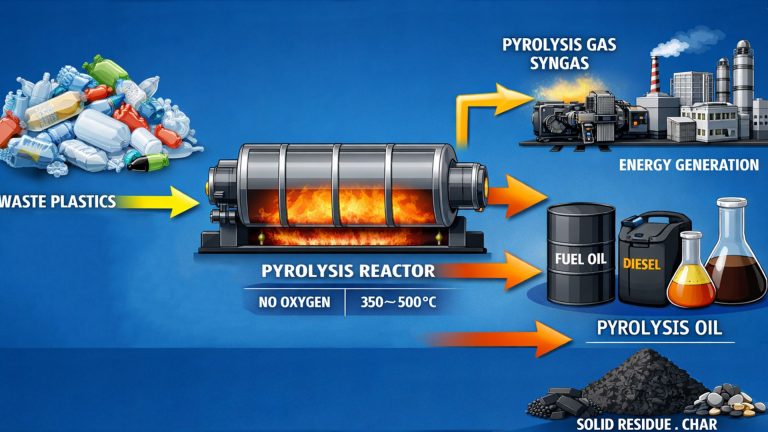

Pyrolysis Of Waste Plastics Into Fuels

Pyrolysis of waste plastics into fuels, a common method of thermochemical conversion, is a popular and promising option in municipal solid waste recycling. Compared to biological recycling, pyrolysis of waste plastics is easier to scale up and can handle unsorted and contaminated waste. Among numerous thermochemical pathways, pyrolysis has received