With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Bio Charcoal Production Equipment Selection

In the industrialized production of biochar, biomass pyrolysis equipment selection is a key factor in determining production efficiency, product quality, environmental compliance, and economic benefits. Bio charcoal production equipment suitability varies significantly across scales, feedstock types, and application scenarios, necessitating a systematic, multi-dimensional assessment. This can help avoid production losses

Biomass Charcoal Production Equipment with High Economic Returns

Charcoal production equipment uses pyrolysis technology to convert waste biomass into solid biochar. Biochar offers multiple benefits, including stable carbon sequestration, increased agricultural production, and environmental remediation. Biomass pyrolysis plants provide economical solutions for green agriculture and pollution control, while also opening up new avenues for carbon credit trading. Biochar

Unlocking Bio Charcoal Production: Key Takeaways and Practical Guidelines

There are many issues that need to be paid attention to during the bio charcoal production process. Bio charcoal production projects involve many key links, including raw material selection, production process control, product quality, safety and environmental protection. Raw Material Selection and Pretreatment Raw materials fundamentally determine the properties and

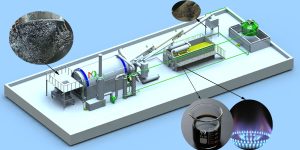

Oil Sludge Treatment Equipment for Resource Recovery

Resource utilization is a key development direction for oil sludge treatment. Mingjie Group provides pyrolysis equipment that helps reduce, decontaminate, and recycle oil sludge waste. Mingjie oil sludge treatment equipment converts oil sludge into fuel oil, carbon black, and syngas through high-temperature pyrolysis. Oil sludge pyrolysis plant not only reduces

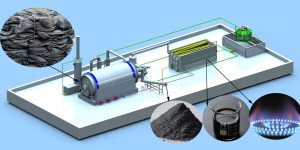

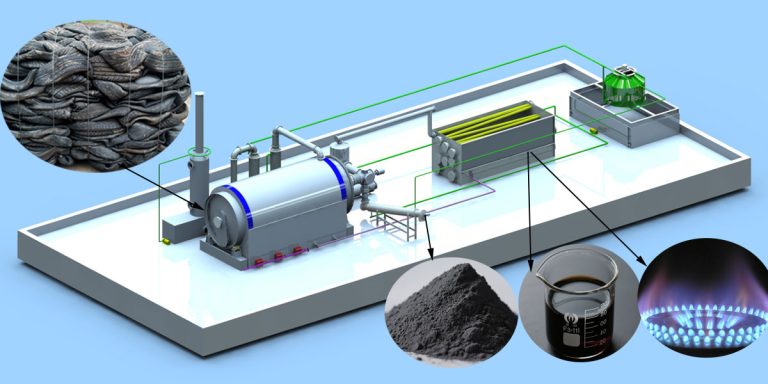

Rubber Pyrolysis Plant – Solution for Solid Waste Recycling

Rubber pyrolysis plant has become a key solution to the problem of rubber solid waste. It uses waste tires, hoses, seals, and other rubber products as raw materials. Through pyrolysis technology, the rubber pyrolysis plant converts waste rubber into fuel oil, combustible gas, and solid carbon black. Pyrolysis has proven

Bio Charcoal Making Machine

Bio charcoal making machine is closely related to the processing of waste biomass and the production of biochar. Biomass carbonization machine is the core equipment for converting various waste biomass into biochar. It plays a vital role in environmental protection and resource utilization. So what is biochar? Biochar is a

Continuous Bamboo Biochar Production Equipment

Choosing the right bamboo biochar production equipment is crucial for reducing costs and improving efficiency. Pyrolysis is the most common method for producing bamboo biochar. Biomass pyrolysis plant heats bamboo in the absence of oxygen, breaking it down to form biochar, bio-oil, and syngas. Mingjie Group provides continuous pyrolysis equipment

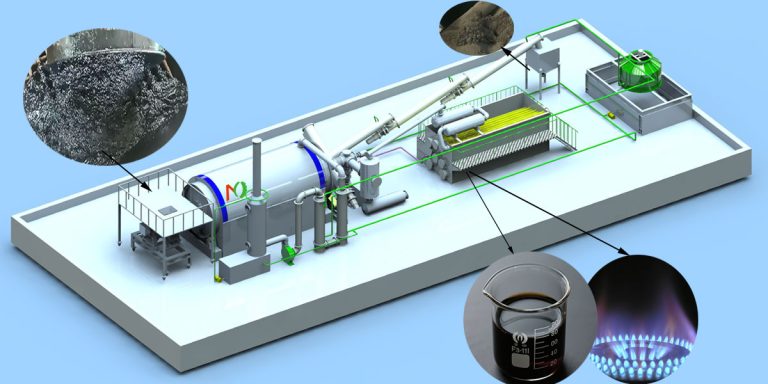

How to Achieve Efficient Production of Rice Husk Charcoal

Mingjie biomass carbonization plant enables efficient production of rice husk charcoal. It primarily utilizes continuous pyrolysis technology, enabling 24-hour continuous biomass feed and biochar discharge. The biomass carbonization equipment utilizes a double-layered cylinder structure to improve biochar production efficiency. The inner cylinder dries the material, while the stainless steel outer

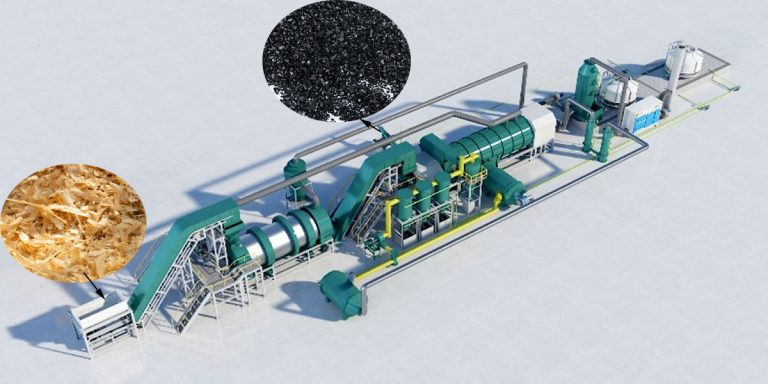

Continuous Carbonization Plant for Biochar Production

Biomass carbonization furnaces commonly suffer from low biochar production efficiency and poor environmental performance. This has hindered the development of the biochar industry. To address these issues, Mingjie Group has designed a continuous carbonization plant. The continuous carbonization plant is mainly composed of feeding system, drying system, carbonization reactor, cooling

Continuous Tyre Pyrolysis Technology

Continuous tyre pyrolysis technology can transform waste tires into high-value-added products of stable quality, including fuel oil, carbon black, steel wire, and combustible gas. Continuous pyrolysis can maximize the recovery and efficient utilization of waste tire resources. It offers high economic and environmental benefits and broad market prospects. Continuous pyrolysis