With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Wood Biochar Production Equipment

The wood biochar production equipment provided by Mingjie Group is a continuous biomass pyrolysis machine. It is a fully automatic charcoal manufacturing machine that integrates drying, preheating, and carbonization. It uses wood chips as raw material for direct continuous feeding and discharging. Most modern biochar plants utilize continuous pyrolysis systems.

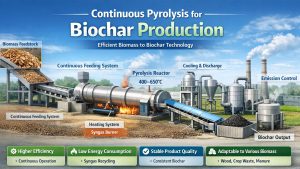

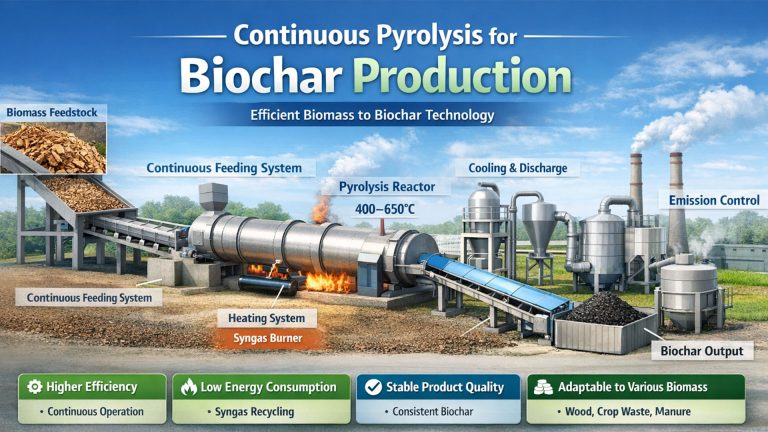

Continuous Pyrolysis for Biochar Production

Continuous pyrolysis for biochar production breaks away from the batch pyrolysis model, enabling continuous feeding of biomass raw materials and continuous discharge of biochar. The biochar production line can operate continuously 24 hours a day without interruption. It can process several tons or even tens of tons of biomass raw

Aluminum Plastic Waste Pyrolysis Equipment

Aluminum plastic composite materials are widely used in packaging, construction, electronics, medical, and many other fields due to their excellent properties such as lightweight, moisture resistance, heat insulation, and corrosion resistance. However, they are among the most difficult wastes to recycle. Currently, the most common treatment method is aluminum plastic

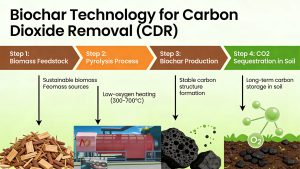

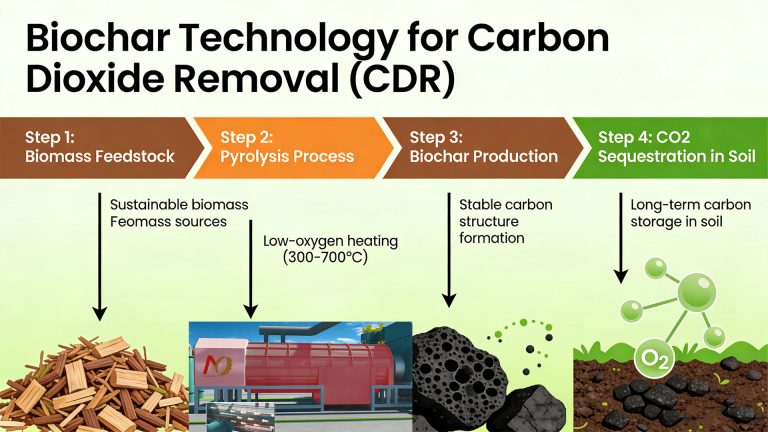

Biochar Technology for Carbon Dioxide Removal CDR

Biochar technology is a process that converts biomass waste (such as crop residues and wood waste) into a stable carbon-based solid material by heating it under oxygen-deficient conditions. This biochar technology was initially used to improve soil health and fertility. However, with the exacerbation of global climate change, biochar has

MJ-15 Plastic Pyrolysis Plant for Sale to Vietnam

In mid-January 2026, Mingjie Group completed the shipment of the MJ-15 plastic pyrolysis plant for sale to Vietnam. The pyrolysis equipment arrived at the port on January 19th. Before dawn, the workers were systematically loading the plastic pyrolysis plant for sale to Vietnam in the workshop. The pyrolysis reactor, feeding

How to Make Biochar from Wood Chips

Pyrolysis is currently the most commonly used method for producing biochar. Making biochar from wood chips is in a high-temperature, oxygen-deficient environment using biomass pyrolysis equipment. The manufacturing process of biochar involves transforming disordered biomass macromolecules through thermochemical conversion, rearranging them into highly ordered aromatic carbon structures. The continuous pyrolysis

Tyre Pyrolysis Carbon Black

Regarding the pyrolysis products of waste tyres, the collection and processing technologies for pyrolysis gas and pyrolysis oil are relatively mature. However, tyre pyrolysis carbon black is increasingly favored by researchers due to its complex composition and diverse applications. The global pyrolytic carbon black market is experiencing a period of

Plastic Pyrolysis To Fuel Oil Plant

The core equipment of plastic pyrolysis to fuel oil plant mainly includes pyrolysis plant and pyrolysis oil distillation plant. The pyrolysis equipment converts waste plastics into primary pyrolysis oil. The distillation equipment refines the primary pyrolysis oil into higher-value fuel. From plastic pyrolysis to fuel oil refining, these equipments is

Pyrolysis Oil Refining for Diesel Fuel Conversion

Pyrolysis oil is a liquid product obtained from the thermal decomposition of waste tires and waste plastics under oxygen-free or oxygen-deficient conditions. Crude pyrolysis oil contains sulfur, chlorine, oxygen-containing compounds, gums, asphaltenes, acidic substances, and highly unstable components. This not only corrodes equipment but also makes it difficult to use

Problems During the Pyrolysis Process of Plastic Waste

Waste plastic pyrolysis plant is an economical and efficient waste plastic treatment equipment that can convert waste plastics into fuel oil, combustible gas, and carbon black. However, the production of wax is a challenging problem during the pyrolysis process of plastic waste. At lower pyrolysis temperatures, the degree of plastic