With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Pyrolysis Technology: End of Life Tyre Recycling Solution

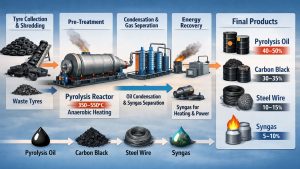

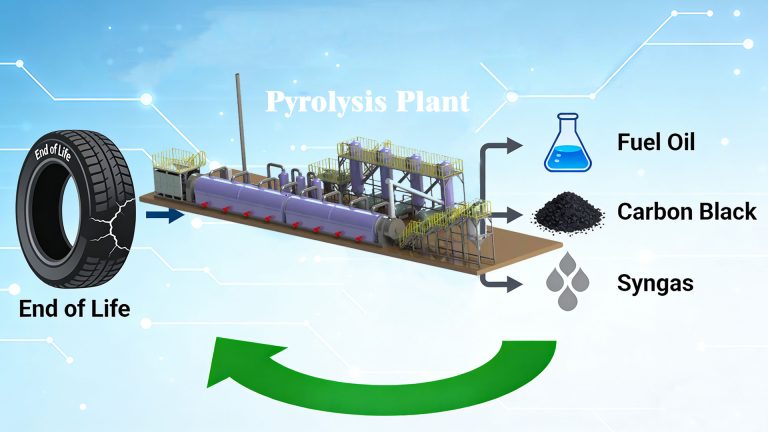

Pyrolysis technology, as an advanced end of life tyre recycling solution, can yield tyre pyrolysis oil (TPO), carbon black, steel wire, and syngas. Tyre pyrolysis oil and recovered carbon black are currently the main focus of market development. They can be used as raw materials in the rubber and chemical

Waste Tyre Disposal by Pyrolysis Technology

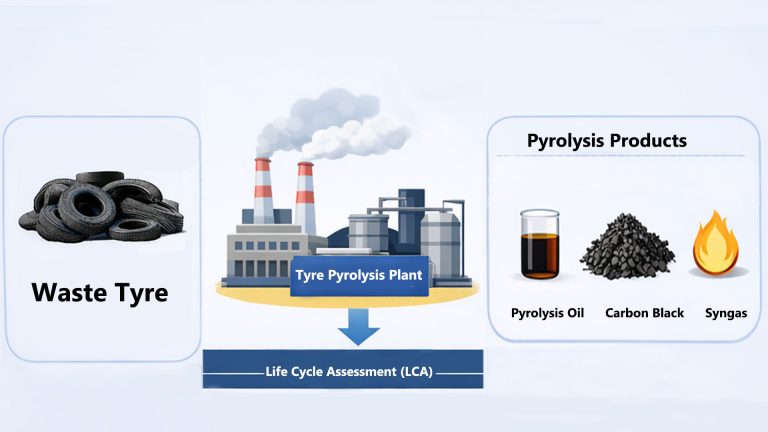

Pyrolysis technology is the most effective treatment technology for waste tyre recycling, and represents the current development direction of waste tyre disposal. Waste tyre pyrolysis is a chemical reaction process carried out in the absence of oxygen or in an inert gas, producing pyrolysis oil, carbon black, synthesis gas, and

Pyrolysis of Waste Tyre for Carbon Emission Reduction

Globally, the market for waste tyre processing is vast and growing. Market research reports indicate that the global waste tire processing market is expected to grow from approximately $15 billion in 2020 to approximately $20 billion by 2025. Pyrolysis of waste tyre, as a promising thermochemical conversion method, demonstrates unique

MJT-1000 Biochar Manufacturing Plant Running

On December 13, 2025, the MJT-1000 biochar manufacturing plant was successfully commissioned and began operation in South Korea. Mingjie biochar production equipment represents a sustainable energy solution. It utilizes continuous pyrolysis technology to convert waste biomass into biochar. Preparations Before Biochar Manufacturing Plant Operation The operation of biomass pyrolysis equipment

Shipment Update: 4 Sets MJ-15 Pyrolysis Equipments Shipped to Argentina

Recently, four sets of MJ-15 pyrolysis equipments were loaded onto a ship at a Chinese port and set sail for Argentina. After several days of road transport, the convoy successfully arrived at the port. Here, the four sets of pyrolysis equipments will be transferred from road transport to sea transport,

MJT-2000 Sawdust Biochar Machine Running

In early December 2025, the MJT-2000 sawdust biochar machine successfully commenced operation in Saudi Arabia. At the client’s site, this biochar production equipment demonstrated an astonishingly efficient and stable output capacity. It has been running continuously and stably for several hours, fully showcasing its excellent stability and reliability. The client

How to Make Biochar from Agricultural Waste

Mingjie biomass carbonization equipment can produce biochar from agricultural waste through continuous pyrolysis technology. It not only processes waste but also generates high-value biochar products. Biochar from agricultural waste is one of the most direct and important ways to achieve negative carbon emissions. It locks waste carbon sources into a

Sludge Biochar Making: Solid Product from Biomass Pyrolysis

In recent years, pyrolysis carbonization technology has developed rapidly, achieving the reduction and resource utilization of sludge. Biomass pyrolysis equipment converts sludge into a high-value functional material, with sludge biochar as the main solid product. Sewage sludge biochar typically possesses a well-developed porous structure, a large specific surface area, abundant

Waste Oil to Diesel Machine

Waste oil to diesel machine can process various waste oils, converting them into clean diesel fuel. The core principle of a waste oil to diesel plant is distillation. Waste oil is heated, vaporized, and condensed, separating and converting it into diesel fuel. Distillation equipment typically operates at a low pressure

MJ-15 Pyrolysis Plant for Sale to Argentina

On December 5, 2025, Mingjie Group completed the shipment of the MJ-15 pyrolysis plant for sale to Argentina from the factory. This customer purchased two pyrolysis units for processing solid waste, thereby converting waste into fuel oil. The MJ-15 pyrolysis plant features a large furnace door design and is equipped