With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Beverage Cans Depainting Machine

The beverage cans depainting machine utilizes pyrolysis technology, eliminating the need for chemical reagents throughout the process. Furthermore, in an oxygen-free or low-oxygen pyrolysis environment, the gases produced by paint decomposition are primarily recyclable pyrolysis gases. After purification, these gases can be reused as fuel, significantly reducing harmful emissions. The

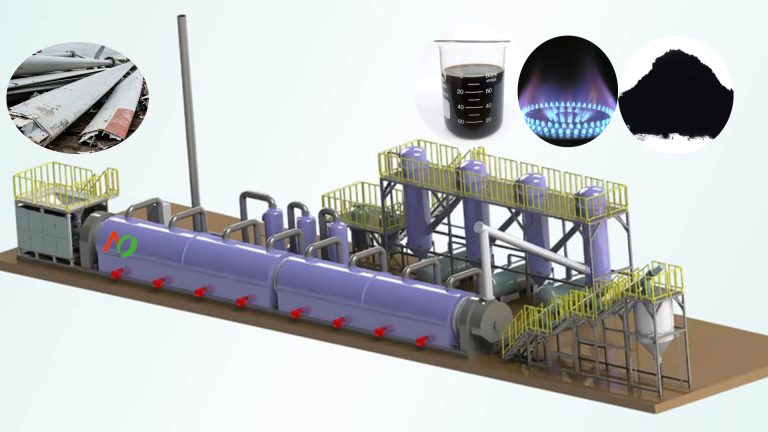

Waste Wind Turbine Blade Pyrolysis

Pyrolysis has emerged as one of the most promising methods for the sustainable treatment of waste wind turbine blades (WWTBs). This is because it effectively recovers high-value products (glass fiber) and generates pyrolysis gas and pyrolysis oil, thereby reducing landfill space waste and harmful emissions. Compared to other end-of-life treatment

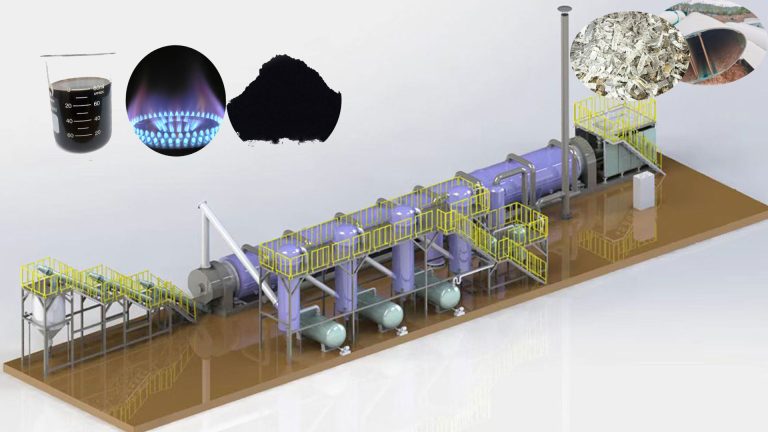

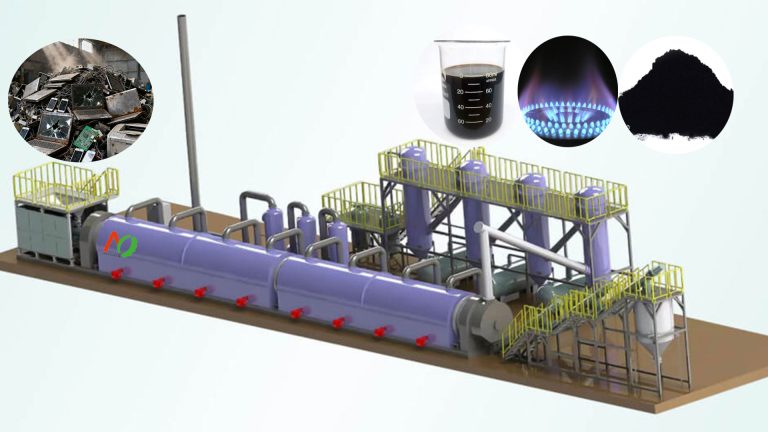

Waste Printed Circuit Board PCB Pyrolysis

Printed circuit board PCB pyrolysis has environmental advantages, while simultaneously utilizing resources such as metals and resins from waste circuit boards. Pyrolysis technology allows for the large-scale processing of waste circuit boards, reducing secondary pollution while recovering resources. PCB pyrolysis involves heating circuit boards under anaerobic or oxygen-deficient conditions, causing

Wind Turbine Blade Recycling

Pyrolysis offers a more advanced method for wind turbine blade recycling. Wind turbine blade pyrolysis involves heating and decomposing organic matter under anaerobic conditions. It can recover glass fibers while converting resins into oil, gas, or solid char, the latter of which can be used as energy. Behind the booming

Metal Cans Depainting Machine

Biomass carbonization equipment can not only convert waste biomass into biochar, but also remove paint from metal cans. Therefore, biomass carbonization equipment is also called metal cans depainting machine. Traditional paint removal methods for aluminum cans include chemical immersion and mechanical polishing. These methods not only waste resources but also

Electrical Waste Pyrolysis Recycling

Electrical Waste Pyrolysis is a thermal decomposition process conducted under anaerobic conditions. This pyrolysis process of E-waste breaks down e-waste into pyrolysis oil, syngas, and solid residues. Pyrolysis plant can process various types of e-waste, including discarded computers, televisions, and smartphones. Its main advantage lies in its ability to recover

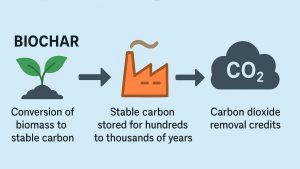

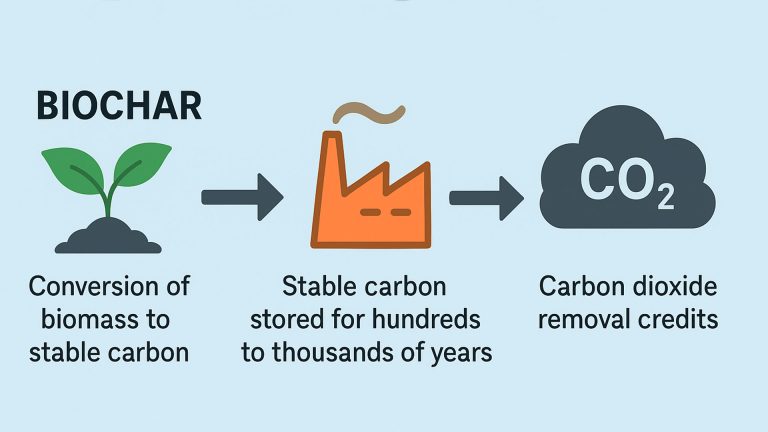

Biochar Market CDR Credits in 2025

The industrial biochar CDR market is tightening at an unprecedented pace. According to new data from the carbon removal market, 89% of biochar CDR credits have been committed by 2025, compared to just 62% in March. The latest analysis shows that buyers are scrambling to secure high-quality credits as demand

Distilling Waste Motor Oil

Waste motor oil is not worthless waste, it possesses enormous resource recycling potential. Distilling waste motor oil can give it new value. Distillation equipment can effectively separate the various components in waste motor oil. It removes impurities and harmful substances, regenerating the waste oil into high-quality base oils. These base

Installation of MJT-2000 Biochar Machine in Saudi Arabia

In November 2025, Mingjie Group provided on-site installation guidance for MJT-2000 biochar machine in Saudi Arabia. After the Saudi customer received the goods, we dispatched technicians to the site. The customer had completed the basic setup, and our technicians then began guiding the next step: assembling the biochar plant. The

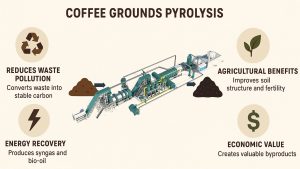

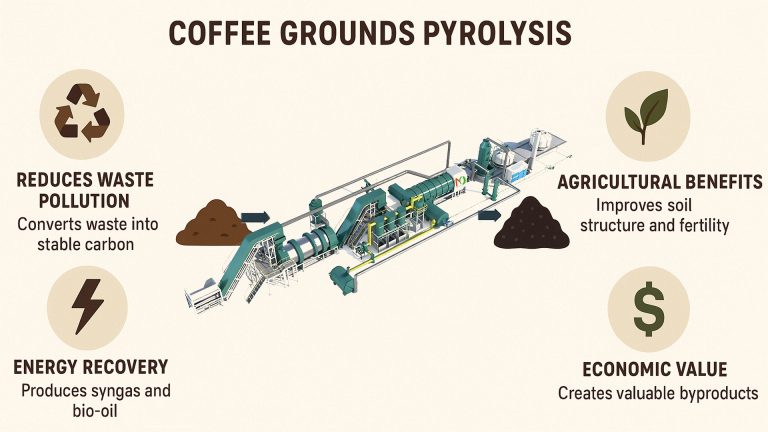

Coffee Grounds Waste Disposal by Pyrolysis Carbonization

Globally, approximately 9 million tons of coffee powder are consumed annually, generating about 18 million tons of wet coffee grounds. Most of these coffee grounds are treated as waste, disposed of through landfills or incineration. Pyrolysis carbonization technology offers a completely new approach to coffee grounds waste disposal, transforming them