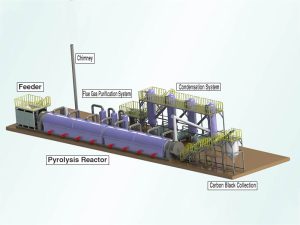

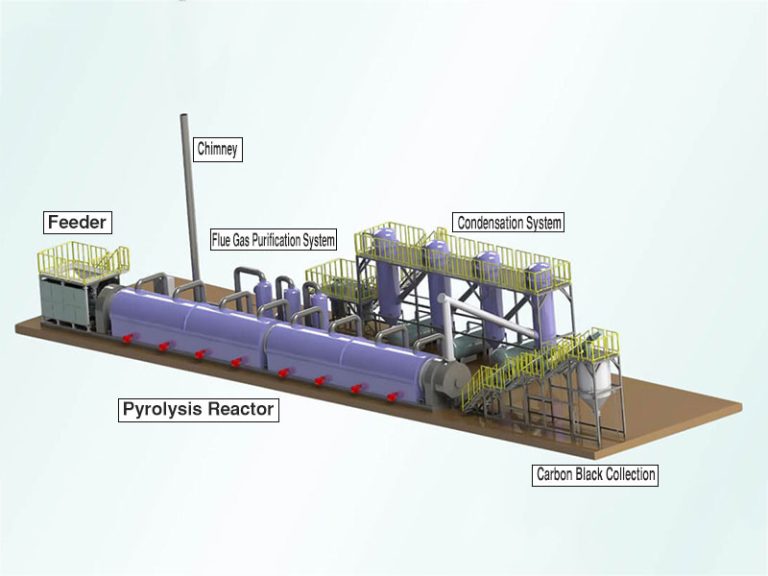

With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Tire To Diesel Recycling Plant – Converts Waste into Energy

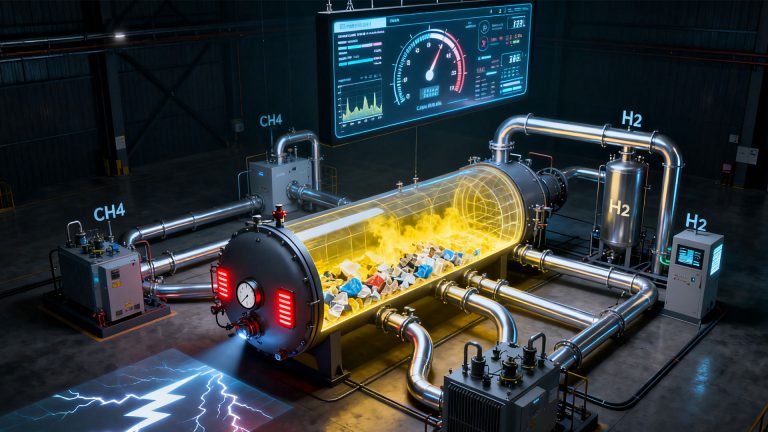

The key technology supporting the operation of tire to diesel recycling plant is pyrolysis. Pyrolysis is a process that breaks down organic matter into smaller molecules under high temperatures in an oxygen-free or low-oxygen environment. For waste tires, pyrolysis effectively breaks down the complex polymer structure of the rubber in

Pyrolysis Waste to Oil

The global pyrolysis waste to oil market is showing strong growth. According to data from relevant market research institutions, the global waste-derived pyrolysis oil market reached a considerable size in 2024. It is expected to grow further through 2030, maintaining a compound annual growth rate (CAGR) during the forecast period.

Environmental Impact of Continuous Tire Pyrolysis Equipment

The environmental impact of continuous tire pyrolysis equipment is a complex issue that requires an objective approach. While it offers significant positive environmental benefits, it also carries potential negative impacts that must be strictly managed. The environmental impact of continuous tire pyrolysis equipment is highly dependent on the sophistication of

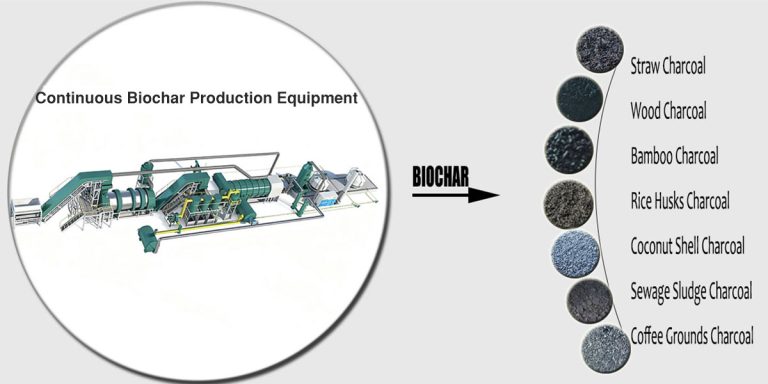

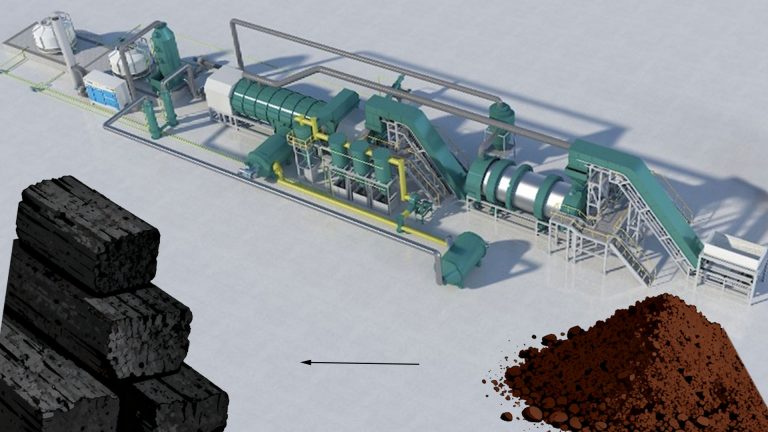

Continuous Biochar Production Equipment for Carbon Emission Reduction

Continuous biochar production equipment converts biomass into biochar, while also operating a complete carbon reduction system. Continuous biochar production equipment is a key component in achieving carbon reduction. Its application value is reflected in the following three aspects. Direct Emission Reduction – Biomass to Biochar Production Biomass carbonization plant achieves

Industrial Plastic Pyrolysis Plant

Mingjie industrial plastic pyrolysis plant is a waste plastic processing and recycling line, designed for waste municipal plastics, marine plastics, and medical plastics. As a leading Chinese manufacturer of pyrolysis technology and equipment, Mingjie Group boasts an advanced pyrolysis technology R&D and equipment manufacturing industrial park. We are committed to

Global Biomass Carbonization Project Development Panoramic Analysis Report

Biomass carbonization technology, as a core technology for converting biomass into high-value-added carbon materials, is gaining increasing attention and application worldwide. Against the backdrop of global climate change and energy transition, biomass carbonization projects are being implemented and applied in various countries. It not only provides a sustainable way to

Solid Waste Pyrolysis Equipment Running in South Africa

Recently, Mingjie company received feedback from South African customers about their waste tire pyrolysis project. The client stated that their waste tire pyrolysis project has started running and has achieved good results. The following pictures show the solid waste pyrolysis equipment running site. The successful operation of the client’s tire

Plastic Waste to Energy Pyrolysis

Plastic waste to energy pyrolysis technology is moving from the laboratory to industrial scale. It’s not the sole solution to the plastics crisis, but rather a powerful and indispensable complement to mechanical recycling. Pyrolysis plant can transform plastic waste into a valuable resource, contributing to a sustainable future. The main

Impact of Biomass to Biochar Production Plant on Global Ecology

The emergence of biomass to biochar production plant has brought a timely relief to the global environment. It is having a positive and far-reaching impact in many key areas, becoming a powerful tool for protecting the Earth’s ecology. Every day, vast quantities of biomass waste are generated, from straw in

Complete Guide to Making Biochar from Coffee Grounds

Coffee, one of the most consumed beverages worldwide, generates millions of tons of coffee grounds waste annually. These grounds are a high-quality raw material for biochar production. Biochar from coffee grounds can not only improve soil fertility, but also sequester carbon, reduce emissions, and purify water. The pyrolysis carbonization process