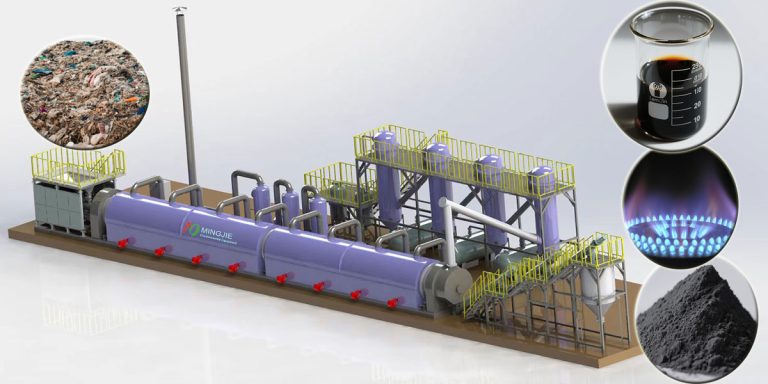

With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

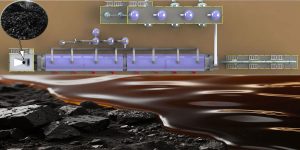

Waste Plastic Pyrolysis Products Applications

Plastic pyrolysis plant can transform discarded plastics into valuable products, such as fuel oil, synthesis gas, and carbon black. These plastic pyrolysis products have broad application prospects in various fields, including energy, chemicals, and materials. It is gradually changing our view of plastic waste and providing a new way to

Plastic Pyrolysis Technology for Recycling Plant

Plastic pyrolysis technology is an economical and efficient method for processing waste plastics, converting them into fuel oil, syngas, and carbon black. Currently, plastic pyrolysis technologies are primarily categorized into conventional pyrolysis, catalytic pyrolysis, and plasma pyrolysis. Conventional pyrolysis is the most basic pyrolysis method, directly decomposing the plastic at

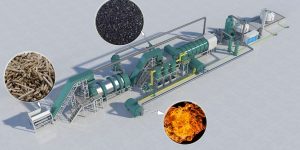

Pyrolysis in Biomass to Efficient Biochar Production

The pyrolysis in biomass is currently the most commonly used method for producing biochar. Pyrolysis involves placing biomass feedstock in an oxygen-deficient or oxygen-reduced carbonization furnace, where it undergoes a high-temperature pyrolysis reaction to produce biochar. As the core equipment for biochar production, biomass pyrolysis machines play a crucial role

Waste Tyre Recycling Pyrolysis Market Analysis

The entire tire lifecycle consists of three key steps: tire production, waste tire collection, and waste tire recycling. Waste tyre recycling plants prioritize waste tires based on quality, from high to low. High-quality tires are directly retreaded, medium-quality tires are used to produce recycled rubber and rubber powder, and low-quality

Waste Tire Disposal – Pyrolysis Plant Project

Murfitts Industries, the UK’s largest tire recycler, and tire giant Michelin have jointly announced a waste tire disposal and pyrolysis plant project. The tire pyrolysis plant focuses on recovering energy and materials from waste tires. Murfitts plans to invest £14 million to build a waste tire recycling and pyrolysis facility

Biochar Making Equipment for Sustainable Biomass Solution

Mingjie biochar making equipment is a sustainable waste biomass solution. It uses biomass pyrolysis technology to convert biomass into a solid carbonaceous material – biochar under oxygen-free and high-temperature conditions. The biochar making machine can process a variety of biomass raw materials, including agricultural waste, forestry residues, and organic waste

Impact of Biomass Carbonization Equipment on Carbon Sinks

Biomass carbonization equipment has a positive impact on carbon sinks. It converts waste biomass into biochar through continuous pyrolysis technology, thereby reducing greenhouse gas emissions. Biomass carbonization equipment can process a variety of waste biomass, such as crop straw, forestry waste, and livestock manure, converting it into biochar with both

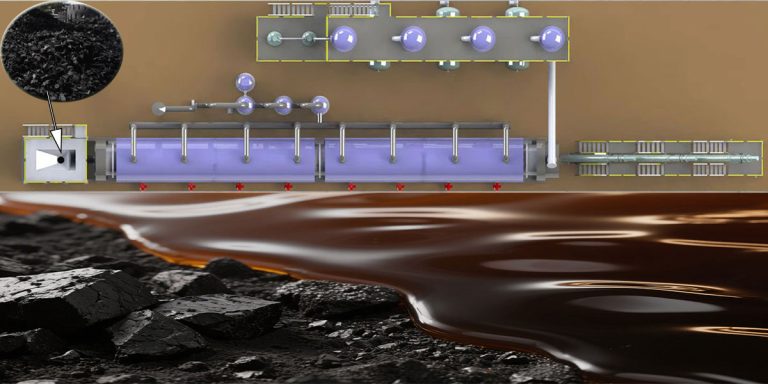

Plastic Energy Pyrolysis from Waste to Fuel Oil

Advanced recycling encompasses innovative technologies that go beyond mechanical recycling. Pyrolysis, one of the more established forms of advanced recycling, appears poised for growth in the coming years. Pyrolysis technology uses heat between 300°C and 600°C in the absence of oxygen to decompose various waste products, such as plastics, municipal

Plastic Pyrolysis Recycling

Pyrolysis is a leading and growing technology for upcycling waste plastics. Plastic Pyrolysis Recycling plant is particularly suitable for recycling PP, PE, and PS plastics to produce syngas, fuel oil, and solid carbon black products. Plastic pyrolysis plant can process plastics that are currently difficult to recycle using mechanical recycling

MJ-2 Small Plastic Pyrolysis Machine for Sale to Morocco

On August 18, 2025, Mingjie Group completed the shipment of MJ-2 skid-mounted small plastic pyrolysis machine for sale to Morocco. The small-scale pyrolysis plant is one of our best-selling pyrolysis equipment, capable of processing 1-2 tons/day of waste plastic/tire. It features low cost, a small footprint, and requires no installation.