With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

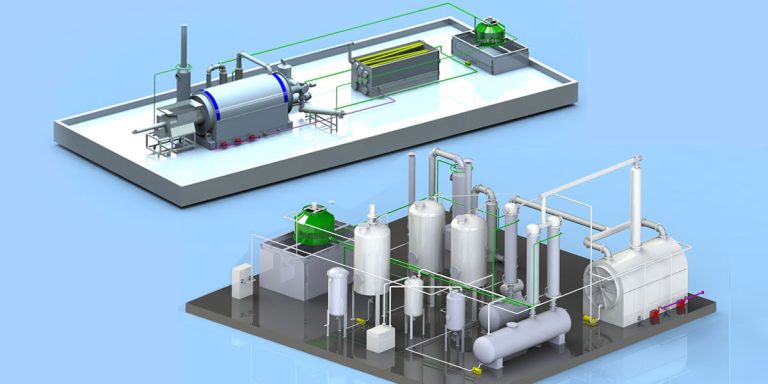

What Equipment is Needed for Pyrolysis Plastic To Diesel

Mingjie Group provides plastic pyrolysis plant and pyrolysis oil distillation plant for pyrolysis plastic to diesel. They play a key role in connecting upstream and downstream in the plastic waste resource utilization industry chain, and jointly realize the transformation of “waste plastic → pyrolysis oil → diesel”. The core of

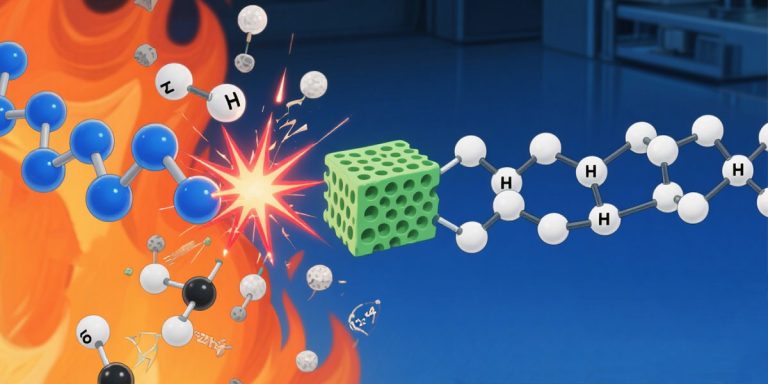

Waste Plastic Pyrolysis Process for Chemical Recycling

The plastic pyrolysis process uses chemical recycling to process waste plastics. The main components of waste plastics are high molecular polymers (polyethylene PE, polypropylene PP, polystyrene PS). Plastic pyrolysis plant decomposes plastic waste thermally under oxygen-free conditions, converting it into valuable products such as fuel oil, syngas, and carbon black.

Pyrolysis Plastic Waste To Energy Plant

Waste plastic pyrolysis oil (WPPO) is a new and potentially valuable raw material produced during the pyrolysis process of waste plastics. Plastic waste to energy plant recycles waste plastics through pyrolysis. They use heat at 300°C-600°C in the absence of oxygen to decompose waste plastics and municipal solid waste, producing

Pyrolysis Plant for Waste Plastic

As an innovative solid waste treatment solution, plastic pyrolysis is becoming a key force in solving plastic pollution and resource crises. The pyrolysis plant for waste plastic plays a crucial role in environmental protection and resource utilization. The pyrolysis plant for waste plastic consists of various systems, including feeding system,

MJT-1000 Biochar Machine For Sale to South Korea

On August 12, 2025, Mingjie Group completed the shipment of MJT-1000 biochar machine for sale to South Korea. It provides an efficient solution for converting biomass waste into charcoal. We provide customers with a series of supporting equipment, such as dryers, electric control cabinets, flue gas purification devices, etc. The

How to Make Cow Dung Charcoal Efficiently

The charcoal making machine can efficiently convert cow dung into biochar through continuous pyrolysis carbonization. The cow dung charcoal is rich in nutrients, such as phosphorus and potassium, making it a valuable soil fertilizer. Pyrolysis technology involves using high temperatures in an oxygen-free or low-oxygen environment to decompose and transform

Sawdust Charcoal Machine for Sale

In the world of wood processing, sawdust, these seemingly insignificant, fine debris, is an inevitable byproduct. In the past, it was often discarded as worthless waste, resulting in a significant waste of resources and a potential environmental burden. Sawdust charcoal machine can help realize the valuable value of sawdust by

Bamboo Biochar Making by Continuous Pyrolysis

With the widespread use of bamboo, the amount of waste bamboo is also increasing. Discarded bamboo products due to damage and aging have become a pressing issue. Biomass pyrolysis technology offers a new approach to addressing this challenge. Biomass carbonization plant uses continuous pyrolysis technology for bamboo biochar making. The

Organic Waste Pyrolysis Treatment

Pyrolysis technology provides an important way for solid waste resource utilization and energy recovery. Waste pyrolysis is particularly suitable for treating solid waste rich in organic matter (such as waste plastics, waste rubber, biomass waste, sludge, etc.) Pyrolysis is the most effective method for recycling organic waste. This method involves

Pyrolysis Of Solid Waste to Achieve Harmless Disposal

The primary purpose of pyrolysis of solid waste is to achieve harmless disposal. It is a thermochemical conversion technology. Pyrolysis of solid waste uses heat in the absence or absence of oxygen to break down organic matter into storable fuels (pyrolysis oil, syngas) and a solid residue (carbon black/biochar). This