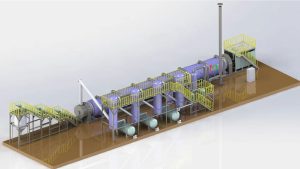

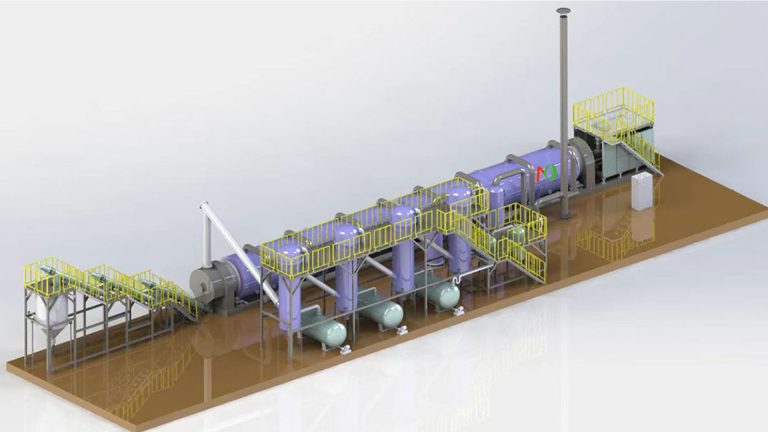

With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Waste Tire to Oil Plant for Resource Recovery

Tire pyrolysis plant can convert waste tires into pyrolysis oil (fuel), syngas (energy), steel wire (scrap metal), and carbon black. The main application areas of waste tire to oil plant include fuel oil production, carbon black manufacturing, and steel wire recycling. In 2024, global production of fuel oil extracted from

Waste Tyre to Oil Plant Market

The waste tyre to oil plant have become key technological equipment for solving the challenges of solid waste and hazardous waste treatment. Because of its core advantages of reduction, harmlessness, and resource utilization. Tyre pyrolysis plant provides efficient and feasible solutions for sustainable waste management systems, and the market is

Waste Tire to Oil Pyrolysis Technology

Waste tire to oil pyrolysis technology is an important method for processing rubber. The pyrolysis system primarily works by utilizing the principle that rubber undergoes cracking at high temperatures. In a high-temperature, oxygen-free or oxygen-deficient environment, the components of waste tires undergo complex chemical reactions. During the waste tire to

Waste Tire to Oil Pyrolysis Plant for Sustainable Development

Waste tire to oil pyrolysis plant has become an engineered solution that combines resource recycling and economic benefits. Facing the pressure of managing billions of waste tires globally each year, pyrolysis technology represents a way to transform waste into valuable resources. Tire pyrolysis plant not only recovers high-value pyrolysis products,

Waste Wind Blade Recycling Methods

Currently, there are two main methods for waste wind blade recycling: mechanical recycling and chemical recycling. Chemical recycling is further divided into solvent recycling and pyrolysis recycling. Wind turbine blades are the core components that convert wind energy into electrical energy. To adapt to harsh natural conditions, reduce the weight

How to Make Biochar from Animal Manure

Making biochar from animal manure is a highly promising waste resource utilization pathway. It connects animal husbandry, environmental protection, and agriculture, aligning with the concept of sustainable development. Mingjie biomass carbonization plant can convert animal manure into biochar. Animal manure is an excellent raw material for biochar production, primarily due

MJT-3000 Wood Biochar Production Plant Running

The MJT-3000 wood biochar production plant has been operational for 5 months since its installation in South Africa was completed. It can process 2500-3000 kg of wood chips per hour and convert them into biochar. The biochar production equipment utilizes continuous pyrolysis technology to fix the carbon in biomass into

Waste Biomass Pyrolysis for Green Energy

The core contribution of waste biomass pyrolysis technology to energy and environmental protection lies in transforming waste into valuable resources. It not only produces renewable energy, but also achieves long-term carbon sequestration and reduces environmental pollution from waste. Biomass pyrolysis involves heating biomass (straw, wood chips) under oxygen-deficient conditions to

Waste Plastic Recycling for Low Carbon

According to statistics, hundreds of millions of tons of waste plastic are generated globally every year, but the proportion that is effectively recycled remains low. How to achieve efficient waste plastic recycling has become an important issue in the circular economy and sustainable development. Common waste plastics include PET, HDPE,

Waste Plastic Disposal by Pyrolysis Technology

In municipal solid waste management, pyrolysis technology demonstrates exceptional volume reduction capabilities in the waste plastic disposal. It is gradually becoming a key force in alleviating the pressure on landfills and incineration facilities. Pyrolysis technology, as a new method for waste plastic disposal, differs fundamentally from traditional landfill and incineration.