With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Plastic to Diesel Plant

The plastic to diesel plant helps reduce oil consumption, carbon dioxide emissions, and the amount of waste requiring disposal. Furthermore, plastics can be converted into useful products. The pyrolysis process for converting plastic into diesel is one of the most dynamic areas in the plastics industry today. The key advantage

Plastic to Fuel Machine

The core of the The plastic to fuel machine converts mixed plastics into pyrolysis oil, syngas, and carbon black in an oxygen-free environment. One ton of plastic can produce 700 liters of diesel fuel, with carbon emissions 60% lower than fossil fuels., which converts waste into energy, lies in pyrolysis

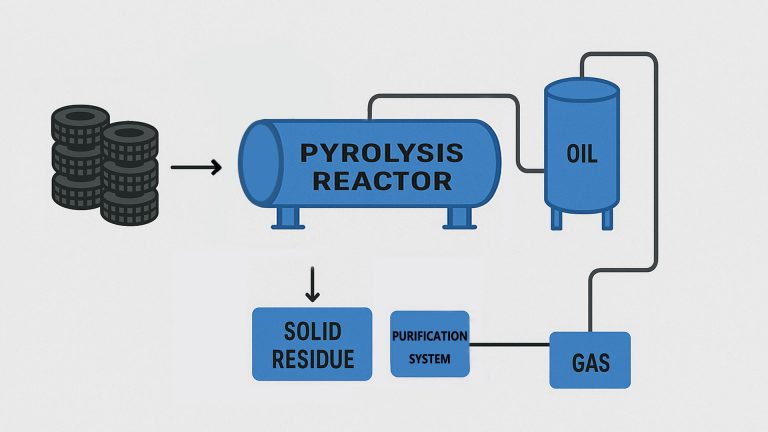

Extracting Oil from Tyres by Pyrolysis Plant

Extracting oil from tyres relies on pyrolysis plant to complete this chemical conversion process. Rubber is the key component in this conversion. During pyrolysis, the oxygen-free, high-temperature environment inside the pyrolysis plant breaks the chemical bonds in the rubber molecular chains. The previously tightly linked macromolecular structure is broken down,

Tire to Oil Plant Turns Rubber into Fuel

The tire to oil plant is an industrial facility specifically designed to convert waste tires into reusable resources. It plays an increasingly important role in resource recycling and environmental protection. The tire to oil plant operates on the principle of pyrolysis technology. This is a process that decomposes organic matter

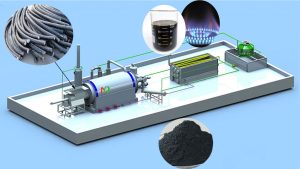

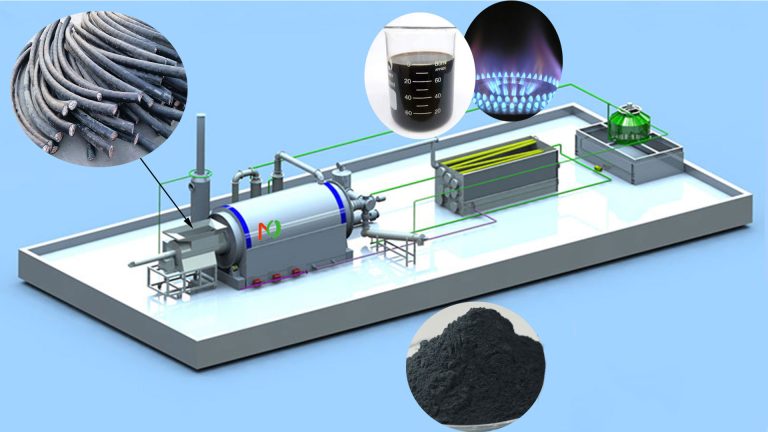

Pyrolysis of Waste Cable

Pyrolysis of waste cable involves heating the cable insulation layer under anaerobic or oxygen-deficient conditions to cause thermal decomposition of the polymer molecules. The pyrolysis of waste cable process occurs within a temperature range of 300-450℃ and lasts for 90-120 minutes. Within this temperature range, the carbon-carbon bonds in the

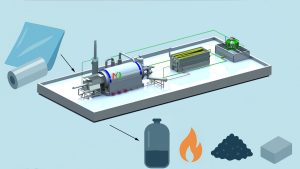

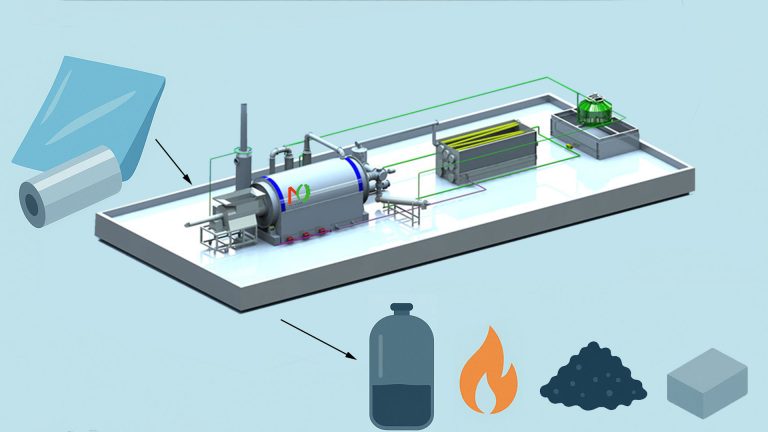

Aluminum Plastic Pyrolysis Recycling Technology

Aluminum plastic composites are typically made by tightly bonding polyethylene (PE) or polypropylene (PP) plastic film with aluminum foil using adhesives. This strong bond is a nightmare for traditional recycling processes. Aluminum plastic pyrolysis, as a more efficient and environmentally friendly resource recovery technology, is gradually becoming a solution for

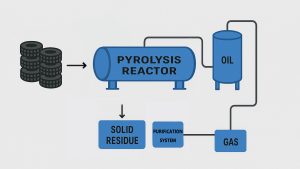

Waste Tyre to Oil Plant

The core function of waste tyre to oil plant is to convert waste tires into usable oil products through a series of processes. Pyrolysis is the key technology. The entire waste tyre to oil process can be broadly divided into four main stages: pyrolysis, condensation, separation, and distillation. Waste Tyre

How to Obtain Quality Pyrolysis Oil from Plastic

Precise temperature control is one of the most critical technical aspects in the production of pyrolysis oil from plastic waste. The pyrolysis temperature plays a decisive role in the oil yield and product quality of waste plastics. Different types of plastics, due to differences in their chemical structure and molecular

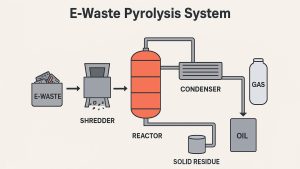

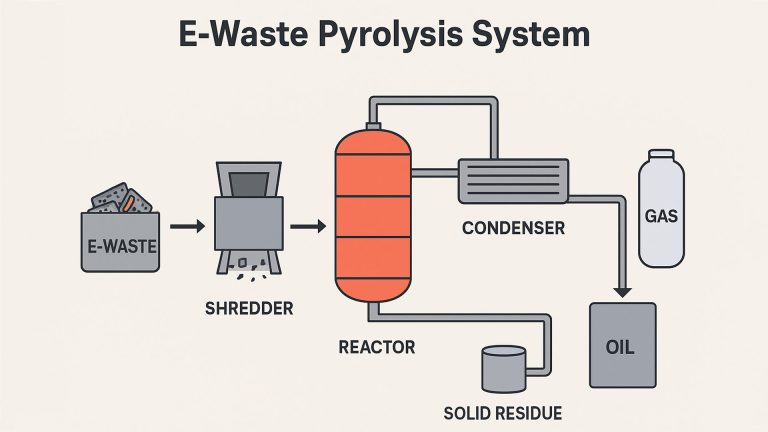

Pyrolysis Of E Waste for Resource Recovery

Pyrolysis of E Waste is primarily applied to the refined recycling of waste PCBs, the recycling of plastics from waste household appliances, the separation of cables and composite materials, and the deep resource recovery of waste mobile phone dismantling plants. The value of pyrolysis technology in the field of electronic

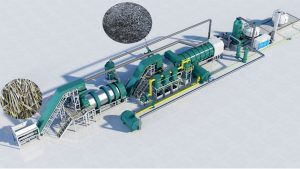

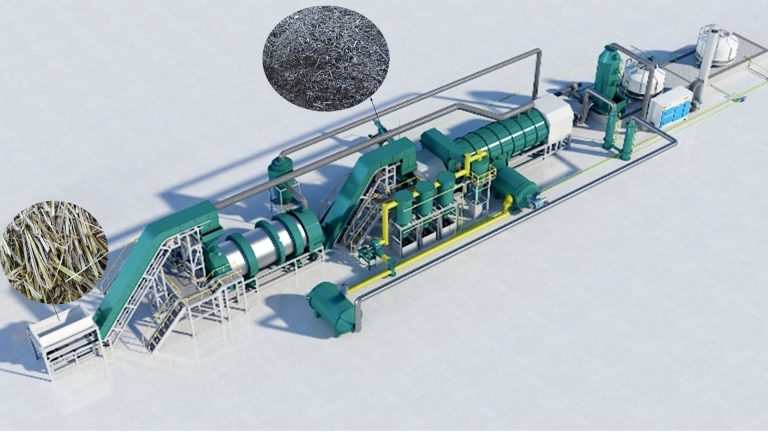

Straw Biochar Production Equipment

Straw biochar production equipment is key to converting straw into high-value biochar. It mainly includes several important systems: feeding system, pyrolysis carbonization reactor, biochar cooling and collection system, energy recovery system and exhaust treatment system. Mingjie’s straw biochar production equipment employs a continuous pyrolysis carbonization process, enabling 24-hour uninterrupted operation.