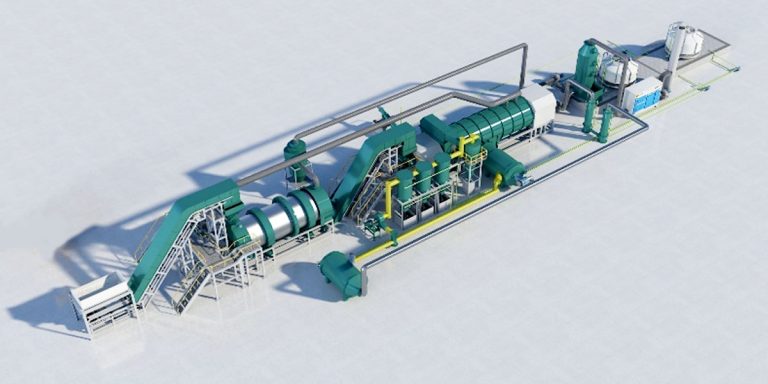

With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Tyre Pyrolysis Plant Manufacturer

Mingjie Group, a tyre pyrolysis plant manufacturer, uses innovative technology to transform waste tires into valuable energy and resources. By incorporating pyrolysis technology into its equipment, it embodies the circular economy concept of turning waste into treasure. Mingjie Group offers a variety of waste treatment solutions, including pyrolysis equipment for

Pyrolysis Of Rubber Tyres

With its triple advantages of volume reduction, harmlessness, and resource utilization, pyrolysis of rubber tyres is becoming a sustainable solution to the waste tire problem, giving “black waste” a green life. Amidst global industrialization and the widespread adoption of automobiles, rubber tires have become a crucial cornerstone of modern transportation,

Waste Tyre Pyrolysis Plant Supplier

Amidst the booming environmental protection industry, the tyre pyrolysis equipment market is experiencing significant growth. Mingjie Group, as a premium tyre pyrolysis plant supplier, offers comprehensive tyre pyrolysis solutions, enabling the conversion of waste tyres into diesel. Waste tyre pyrolysis is an effective and sustainable solution for solid waste management.

Biochar Manufacturing Machine for Biomass Processing

Driven by the dual goals of global carbon neutrality and the need for ecological and environmental governance, biomass pyrolysis machines, as a key device for converting waste biomass into biochar, are gradually gaining public attention. Biochar manufacturing machine provide innovative solutions for agricultural soil improvement and environmental pollution control. It

What is Biochar Plant

A biochar plant uses pyrolysis technology to convert waste biomass into biochar. Biochar is a carbon-rich solid formed by the high-temperature pyrolysis of waste biomass in an oxygen-free or anoxic environment. It has a high carbon content, a rich pore structure, a large specific surface area, and a high number

Best Biochar Machine Manufacturer

As one of the few solutions that can actively remove carbon from the atmosphere, biochar technology is playing an increasingly important role in global carbon neutrality strategies. Choosing the right biochar machine manufacturer is not only an economic decision, but also an investment in a sustainable future. With the improvement

Charcoal Production Equipment Converts Biomass to Biochar

Biochar is becoming a popular category in the voluntary carbon market. According to MSCI data, demand for biochar credits has doubled annually over the past two years. Charcoal production equipment, as an essential biomass-to-biochar conversion device, is increasingly becoming a critical bridge between waste management and resource recovery. Biochar, a

Tyre Pyrolysis to Fuel Plant

Mingjie tyre pyrolysis to fuel plant can convert waste tyres into valuable energy sources, such as pyrolysis oil, carbon black, steel wire, and syngas. It primarily utilizes pyrolysis technology for thermochemical conversion. In a specialized, oxygen-free or low-oxygen environment, pyrolysis equipment uses indirect heating to cause the organic polymer compounds

Waste Plastic Pyrolysis To Fuel Plant for Recycling

Mingjie plastic pyrolysis to fuel plant can process waste unsuitable for mechanical recycling. It will address the need for high-quality recycled material solutions, giving new life to plastic waste that currently cannot be mechanically recycled. This plastic waste is converted into pyrolysis oil, which can be used to replace raw

Wood Pyrolysis Products with High Value

Wood pyrolysis plant not only fully utilizes wood resources and produces high-value products, but also provides new ideas and solutions for sustainable development. The wood pyrolysis process produces a rich and diverse array of products. These wood pyrolysis products can be categorized by their physical state: gaseous, liquid, and solid.